WARRANTY................................................................................................................................................................ 4

SAFETY SUMMARY ..................................................................................................................................................... 5

PRINCIPAL SAFETY STANDARDS............................................................................................................................ 5

CALIFORNIA PROPOSITION 65 WARNING........................................................................................................... 5

EMF INFORMATION............................................................................................................................................. 5

PERSONAL PROTECTION...................................................................................................................................... 6

FIRE PREVENTION................................................................................................................................................ 7

HIGH FREQUENCY RADIATION ............................................................................................................................ 8

ARC WELDING .................................................................................................................................................... 8

ELECTRIC SHOCK ................................................................................................................................................. 8

NOISE ................................................................................................................................................................. 9

ADDITIONAL SAFETY INFORMATION ................................................................................................................... 9

TABLE OF CONTENTS................................................................................................................................................ 10

INSTALLATION.......................................................................................................................................................... 11

WELDER SPECIFICATIONS ................................................................................................................................. 11

SITE SELECTION ................................................................................................................................................ 11

POWER SOURCE CONNECTION........................................................................................................................ 11

VENTILATION..................................................................................................................................................... 11

ADDITIONAL WARNINGS .................................................................................................................................. 12

ASSEMBLY................................................................................................................................................................ 12

TORCH LEAD AND SPOOL GUN ASSEMBLY........................................................................................................ 12

GAS CYLINDER AND REGULATOR CONNECTION............................................................................................... 12

SHIELDING GAS GUIDE...................................................................................................................................... 13

WIRE LOADING ................................................................................................................................................. 13

REPLACING THE WIRE LINER .............................................................................................................................. 14

HOW TO CHOOSE THE WIRE LINER FOR DIRECT AND EURO CONNECT TORCHES............................................. 14

FLUXCORE WIRE WELDING, “FCAW” ................................................................................................................. 15

MIG WELDING, “GMAW” .................................................................................................................................. 15

ALUMINUM WELDING ....................................................................................................................................... 15

ARRANGEMENT FOR WELDING WITH A SPOOL GUN........................................................................................ 15

SETTING THE WIRE DRIVE TENSION ................................................................................................................... 17

ADJUSTING THE SPOOL POSITION..................................................................................................................... 17

OPERATION.............................................................................................................................................................. 17

DESCRIPTION..................................................................................................................................................... 17

WELDER CONTROLS .......................................................................................................................................... 18

THERMAL OVERLOAD PROTECTION ................................................................................................................... 21

TECHNICAL DATA INFORMATION GUIDE............................................................................................................ 21

WELDING PREPARATION.................................................................................................................................... 21

FACTORS TO CONSIDER FOR BEST WELDING RESULTS....................................................................................... 22

WELDING WIRE SELECTION............................................................................................................................... 22

GAS SELECTION ................................................................................................................................................ 22

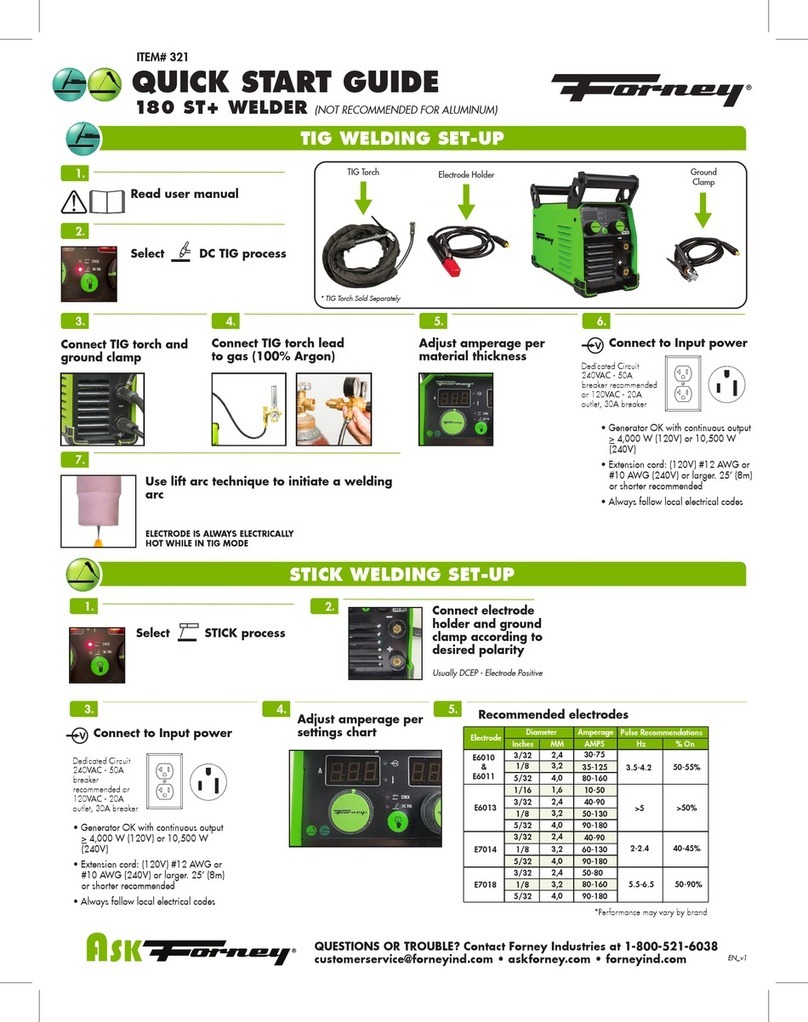

SETUP FOR STICK WELDING (SMAW) ................................................................................................................. 23

SETUP FOR TIG WELDING (GTAW) WITH LIFT ARC .............................................................................................. 23

MIG, GMAW, FLUXCORE WIRE (FCAW) MANUAL WELDING............................................................................... 24

MIG, GMAW, FLUXCORE WIRE (FCAW) SYNERGIC WELDING............................................................................. 25

MIG, GMAW, FLUXCORE WIRE (FCAW) WELDING SETTING CHART .................................................................... 26

MAINTENANCE & SERVICING................................................................................................................................... 27

GENERAL MAINTENANCE ................................................................................................................................. 27

TROUBLSHOOTING................................................................................................................................................... 27

WIRING DIAGRAM ................................................................................................................................................... 30

TOOLS AND SPARE PARTS LIST.................................................................................................................................. 31

PARTS DIAGRAM ...................................................................................................................................................... 32

MIG GUN TORCH SPARE PARTS LIST.......................................................................................................................... 33

USER NOTES ............................................................................................................................................................ 34

Table of Contents