Forno Classico Colosso 65 User manual

!

1!

Installation and

Operation Manual

COLOSSO

–

GO 65

-

26’’

COLOSSO

-

GO 80

-

32’’

COLOSSO

-

GO 100

-

40’’

COLOSSO

-

GO 120

-

48’’

COLOSSO

-

GO 140

-

55’’

COLOSSO

-

GO 160

-

63’’

COLOSSO SERIES

Gas

-

Fire Model

ITALIAN BRICK OVEN

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino info@fornoclassico.com

Goleta, CA 93117 USA www.fornoclassico.com

!

2!

!!

!

TA B LE& O F& C ON T EN TS !

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

COMMERCIAL OVEN SPECIFICATION APPENDIX

COLOSSO SERIES..............................................................3

CAUTIONS & WARININGS...............................................4-5

UNLOADING & WARNING...............................................6-7

INSTALLATION CLEARANCES........................................8-9

OUTDOOR INSTALLATION...............................................10

GAS SPECIFICATIONS................................................11-12

VENTING.....................................................................13-15

LIGHTING THE OVEN..................................................16-17

FLAME CONTROL............................................................18

GAS OVEN MANTENENS.................................................19

CURING THE OVEN..........................................................20

COOKING ENVIROMENT..................................................21

OVEN MAINTENACE.........................................................22

WARRANTY & LIABILITY...................................................23

!

!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino inf[email protected]

Goleta, CA 93117 USA www.fornoclassico.com

!

3!

INSTALLATION AND OPERATION MANUAL THE FORNO

CLASSICO COLOSSO SERIES

COLOSSO

-

GO

-

65/26’’ COLOSSO

-

GO

-

80/32’’

COLOSSO

-

GO

-

100/40’’ COLOSSO

-

GO

-

120

-

48’’

COLOSSO

-

GO

-

140/55’’ COLOSSO

-

GO

-

160

-

63’’

GAS-FIRED & GAS/WOOD COMBINATION MODELS ADDITIONAL COPIES

AVAILABLE UPON REQUEST

!!

!

Oven%Model%!

Commercial*Oven*Series!Colosso%!

!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino inf[email protected]

Goleta, CA 93117 USA www.fornoclassico.com

!

4!

!

!

!

!

!

!

!

!

!

!

!

!

!

Traditional Series

Installation and Operation Manual

An ongoing program of product improvement may require us to change

specifications without notice. WS-TS Installation Manual,

Revised September 2016. Doc no: M0119.04

info@woodstone-corp.com or visit woodstone-corp.com

Wood Stone Corporation

1801 W. Bakerview Rd.

Bellingham, WA 98226 USA

Toll Free 800.988.8103

Tel 360.650.1111

Fax 360.650.1166

4

IN THE EVENT OF A POWER FAILURE, NO ATTEMPT SHOULD BE MADE TO OPERATE THE OVEN.

WOOD STONE TRADITIONAL SERIES GAS-FIRED AND GAS/WOOD COMBINATION OVEN

INSTALLATION AND OPERATING INSTRUCTIONS

CAUTIONS AND WARNINGS

IMPORTANT: Consult your local gas supplier for a statement outlining a procedure to be followed in the

event you smell gas. Post the statement in a prominent location.

READ ALL INSTRUCTIONS BEFORE INSTALLING AND USING THIS APPLIANCE

Please read this entire manual before you install the oven. Failure to follow instructions may result in

property damage, bodily injury or even death. Contact your local building or fire officials about restrictions

and installation inspection in your area.

IMPORTANT: It is recommended that this oven be installed, maintained and serviced by authorized

professionals.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

Additional copies of this manual at woodstone-corp.com.

For prompt responses to service/maintenance questions, call us at @ 1-800-988-8103.

WHEN THE OVEN IS NOT PROPERLY INSTALLED, A FIRE MAY RESULT.

TO REDUCE RISK OF FIRE, FOLLOW THE INSTALLATION INSTRUCTION.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors or liquids in the vicinity of

this or any other appliance. Also, always keep the area under and around this appliance free and clear of

any and all combustible materials.

CAUTION: Never use gasoline, gasoline-type lantern fuel, kerosene, charcoal lighter fluid or similar

liquids to start or freshen-up a fire in this oven. Keep all such liquids well away from the oven when

in use.

!!

!

CAUTIONS)&)WARNINGS!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino info@fornoclassico.com

Goleta, CA 93117 USA www.fornoclassico.com

!

5!

!

!

!

4!

!

!

!

!

!

!

A!MAJOR!CAUSE!OF!OVEN!RELATED!FIRES!IS!A

!

FAILURE!TO!MAINTAIN!REQUIRED!CLEARANCES

!

TO!COMBUSTIBLE!MATERIAL.!IT!IS!OF!UTMOST

!

IMPORTANCE!THAT!THIS!OVEN!BE!INSTALLED!ONLY

!

IN!ACCORDANCE!WITH!THESE!INSTRUCTIONS.

!

!

USE!!SOLID!!WOOD!!FUEL!!ONLY

!

DO!!NOT!!USE!!PRODUCTS!!NOT!!SPECIFIED!!FOR!!THIS!!OVEN

!

!

CAUTION:!!Never!!use!!gasoline,!!gasoline-type!!lantern!!fuel,!!kerosene,!!charcoal!!lighter!!fluid!!or!!similar

!

liquids!!to!!start!!or!!freshen-up!!a!!fire!!in!!this!!oven.!!Keep!!all!!such!!liquids!!well!!away!!from!!the!!oven!!when!!in

!

use.

!

!

!

CAUTION:!!DISCONNECT!!POWER!!TO!!THE!!OVEN IF REQUIRED!!BEFORE!!SERVICING!!OR!!CLEANING.

!

!

!

WARNING:!!It is recommended that this product!!should !be!!installed!!by!!a!!licensed!!plumber!!or!!gas!!fitter!.

!

!

!

!

SAVE!!THE!!INSTRUCTIONS

!

!

Forno Classico’s gas-fired!!ovens!!have!!been!!tested!!and!!approved!!by!!CSA!!Te s t i n g !!Services,

!

and!!are!!CSA!!Listed!!to!!ANSI!!Z83.11!!-!!2016,!!CSA!!1.8 - 2016,!!and!!to!!NSF/ANSI!!Standard!!4!!-!!2016.

!

!

!

!

!

!

!

!

!

!

!

!!

!

CAUTIONS!&!WARNINGS!

Commercial!Oven!Series!

Installation,!Operation!&!Maintenance!

Traditional Series

Installation and Operation Manual

An ongoing program of product improvement may require us to change

specifications without notice. WS-TS Installation Manual,

Revised September 2016. Doc no: M0119.04

info@woodstone-corp.com or visit woodstone-corp.com

Wood Stone Corporation

1801 W. Bakerview Rd.

Bellingham, WA 98226 USA

Toll Free 800.988.8103

Tel 360.650.1111

Fax 360.650.1166

5

Wood Stone’s gas-fired ovens have been tested and approved by Intertek Testing Services,

and are ETL Listed to ANSI Z83.11b - 2009, CSA 1.8b-2009, UL Subject 2162, ULC-S627-00, UL 737

and to NSF/ANSI Standard 4 - 2009.

A MAJOR CAUSE OF OVEN RELATED FIRES IS A

FAILURE TO MAINTAIN REQUIRED CLEARANCES

TO COMBUSTIBLE MATERIAL. IT IS OF UTMOST

IMPORTANCE THAT THIS OVEN BE INSTALLED ONLY

IN ACCORDANCE WITH THESE INSTRUCTIONS.

SAVE THE INSTRUCTIONS

CAUTIONS AND WARNINGS

WARNING: This product must be installed by a licensed plumber or gas fitter when installed within the

Commonwealth of Massachusetts.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

USE SOLID WOOD FUEL ONLY

DO NOT USE PRODUCTS NOT SPECIFIED FOR THIS OVEN

CAUTION: DISCONNECT POWER TO THE OVEN BEFORE SERVICING OR CLEANING.

!!

!

CAUTIONS)&)WARNINGS!

Commercial*Oven!Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino info@fornoclassico.com

Goleta, CA 93117 USA www.fornoclassico.com

!

6!

Your oven will be shipped via a common carrier from our Goleta, California Facility. The oven will arrive fully

assembled and crated. You will need a forklift to remove the crated oven. Once off the truck the oven can

be moved with a pallet jack. We will notify you when your oven is shipped and provide you with the

tracking information and the trucking company’s contact number. It is always important to call the

trucking company in advance to coordinate the delivery.

Colosso%Oven%%%%%%%%%%%

Model!

Approximate++++++++++++++++++++++

Shipping'Weight!

Minimum&Fork&Length&

Required!

Required(((((((((((((

Forklift))Capacity!

Pallet&Jack&&&&&&&&&&&&&&&

Capacity!

Colosso#################65!

1,200!lbs.!

4’!

3,000!lbs.!

!!!!!!!!!!!!!!2,000!lbs!

Colosso%%%%%%%%%%%%%%%%%80!

2,800!lbs.!

4’!

4.000!lbs.!

3,000#lbs!

Colosso%%%%%%%%%%%%%%%100!

3,000!lbs.!

5’!

4.000!lbs.!

4,000#lbs!

Colosso%%%%%%%%%%%%%%%120!

3,900!lbs.!

6’!

5.000!lbs.!

4,000#lbs!

Colosso%%%%%%%%%%%%%%%%140!

4,200!lbs.!

6’!

6.000!lbs.!

2!x"2,000!lbs!

Colosso%%%%%%%%%%%%%%%%160!

5,000!lbs.!

6’!

6.000!lbs.!

2"x"2,000$lbs!

!

THE OVEN IS VERY HEAVY. MOVING THE OVEN UP OR DOWN

A RAMP OR INCLINE ON A PALLET JACK IS NOT SAFE!

!!

!

UNLOADING)AND)MOVING!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino info@fornoclassico.com

Goleta, CA 93117 USA www.fornoclassico.com

!

7!

DO NOT TURN OVEN ON ITS SIDE

1. USING A CRANE

Once the oven is uncrated and removed from the tie

down pallet it can be lifted and placed using a crane.

Rigging for placement by a crane requires the use of two

sling straps to be located directly beneth the oven base

and on opposite sides. The riggin straps can culminate to

an overhead lifting bar or hook. Each side of the rigging

straps must have tension straps to ensure that the rigging

straps remain spread wide at their bases during the lifting

process.

2. USING A FORKLIFT

Be sure to use a forklift rated, and forks the minimum

length, as shown in Appendix A. Fork extensions must be

used so the forks extend through to the opposite side of

the stand. The oven is very top heavy, so be sure to

spread the forks as far apart as possible

3. USING A PALLET JACK

Once the oven has been removed from the delivery

vehicle, it can easily be moved on flat surfaces using a

pallet jack. If the forks don’t extend across the base, use

4” x 4” posts to bridge the space, placing the forks

underneath for support.

!

!

!

!

!

!

!

!

!

!

LIFTING THE OVEN

!!

!

UNLOADING)AND)MOVING!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino info@fornoclassico.com

Goleta, CA 93117 USA www.fornoclassico.com

!

8!

Traditional Series

Installation and Operation Manual

An ongoing program of product improvement may require us to change

specifications without notice. WS-TS Installation Manual,

Revised September 2016. Doc no: M0119.04

info@woodstone-corp.com or visit woodstone-corp.com

Wood Stone Corporation

1801 W. Bakerview Rd.

Bellingham, WA 98226 USA

Toll Free 800.988.8103

Tel 360.650.1111

Fax 360.650.1166

9

!

WARNING: Installation and servicing of this product could expose you to glasswool/ceramic

fibers as well as calcium silicate dust. ALWAYS WEAR RESPIRATORY AND EYE PROTECTION

WHEN INSTALLING OR SERVICING THIS APPLIANCE. Please read this entire manual before

you install the oven. Failure to follow instructions may result in property damage, bodily

injury or even death. Contact your local building or fire officials about restrictions and

installation inspection in your area.

INSTALLATION CLEARANCES

CLEARANCES

1. The Traditional Series oven is designed to accommodate field application of tile, stucco or other NON-COMBUSTIBLE finishes.

The Wood Stone Traditional Series oven must have a minimum 1" clearance to combustibles from all sides, and 14"

clearance to combustibles from the top (see INSTALLATION CLEARANCES section on next page). If building a facade

that will contact the oven, use completely non-combustible materials*.Please note that standard Drywall (or Sheetrock) is

considered a combustible.

2. If enclosing the oven, any facade materials 6" to either side of the oven doorway and above must be constructed of non-

combustible building materials. All materials in direct contact with, or attached to the oven body, must be non-combustible.

3. Install this oven only on a non-combustible floor surface. (Cet appareil doit être installé sur une surface de plancher non-

combustible.) The non-combustible floor surface should extend 36" out in front of the oven, and extend 30" to either side of

the oven doorway.

*When NON-COMBUSTIBLE building materials contact the body of the appliance, the clearances to combustibles are transferred

to those non-combustibles.

NOTICE: Only non-combustible materials may be applied directly to the oven.

IF THIS OVEN IS NOT PROPERLY INSTALLED A FIRE MAY RESULT. TO REDUCE THE RISK OF FIRE, FOLLOW THESE

INSTALLATION INSTRUCTIONS. A MAJOR CAUSE OF OVEN RELATED FIRES IS FAILURE TO MAINTAIN REQUIRED

CLEARANCES (AIR SPACES) TO COMBUSTIBLE MATERIALS. IT IS OF UTMOST IMPORTANCE THAT THIS OVEN BE

INSTALLED ONLY IN ACCORDANCE WITH THESE INSTRUCTIONS.

WARNING: DO NOT PACK REQUIRED AIR SPACES WITH INSULATION OR OTHER MATERIAL.

PLEASE READ THIS ENTIRE MANUAL BEFORE YOU INSTALL THE OVEN. FAILURE TO FOLLOW INSTRUCTIONS MAY

RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH. CONTACT YOUR LOCAL BUILDING OR FIRE

OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION IN YOUR AREA.

!!

!

INSTALLATION(CLEARANCES!

Commercial*Oven*Series!

Installation,"Operation"&"Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino [email protected]

Goleta, CA 93117 USA www.fornoclassico.com

!

9!

Maintain 6-inch

clearance from the

flue outlet

1-inch minimum side

clearance to

combustible

construction

Non-combustible

floor, 36’’ in front

and 30’’ to

either side of oven

Doorway

(6" to either side of doorway

and above) represents

space where facade

materials must be

non-combustible.

This area must be left

accessible and

unobstructed after

installation for air

intake and routine

service of the oven

burner.

THE FOLLOWING CLEARANCE INFORMATION APPLIES TO ALL

THE COLOSSOSERIES OVENS

Forno Classico ovens carry an CSA Sanitation listing. The oven interior only is CSA listed to

NSF/ANSI Standard 4. Surfaces of the oven, meant to be left exposed after facade installation,

have been evaluated for sanitation and food safety and comply with NSF/ANSI Standard 4. To

operate the oven in accordance with NSF/ANSI Standard 4, only pizza and bread products may

be cooked directly on the floor of the oven. Other types of food may be cooked on or in pans, or

other suitable containers to prevent spillage onto the oven deck.

!!

!

INSTALLATION(CLEARANCES!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino [email protected]

Goleta, CA 93117 USA www.fornoclassico.com

!

10!

!!

!

OUTDOORS'INSTALLATIONS!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino info@fornoclassico.com

Goleta, CA 93117 USA www.fornoclassico.com

!

11!

!

!!

!

GAS$SPECIFICATIONS!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino [email protected]

Goleta, CA 93117 USA www.fornoclassico.com

!

12!

Factory Specified Manifold Pressures (W.C.) and associated BTU/hr. input values

for Forno Classico Commercial Series Ovens

Traditional Series

Installation and Operation Manual

An ongoing program of product improvement may require us to change

specifications without notice. WS-TS Installation Manual,

Revised September 2016. Doc no: M0119.04

info@woodstone-corp.com or visit woodstone-corp.com

Wood Stone Corporation

1801 W. Bakerview Rd.

Bellingham, WA 98226 USA

Toll Free 800.988.8103

Tel 360.650.1111

Fax 360.650.1166

13

Hourly BTU/hr input rates for Wood Stone Traditional Series for models equipped to burn Natural Gas (NG)

Hourly BTU/hr input rates for Wood Stone Traditional Series for models equipped to burn Propane (LP)

Hourly BTU/hr input rates for Wood Stone Traditional Series for models equipped to burn Hot Propane (HLP)

GAS SPECIFICATIONS

Wood Stone recommends that the appliance’s individual shutoff valve (supplied by others) be left readily accessible.

Wood Stone also recommends that inspection and maintenance of the burners and gas piping connections of this

appliance be performed at regularly scheduled intervals and only by professional gas appliance service agencies.

GAS CODE LIMITATIONS

The installation of this appliance must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 or The Natural Gas installation Code CAN/CGA-B149.1 as applicable, including:

The appliance and its individual shutoff valve (supplied by others) must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 psi (3.45 kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve (supplied by

others) during any pressure testing of the gas supply piping system at test pressure, equal to or less than 1/2 psi (3.45 kPa).

Burner Configuration (NG) RFG-IR-W, RFG-IR RFG, RFG-W W-IR

Model

WS-TS-5 188,000 105,000 83,000

WS-TS-6 188,000 105,000 83,000

Burner Configuration (LP) RFG-IR-W, RFG-IR RFG, RFG-W W-IR

Model

WS-TS-5 159,000 94,000 65,000

WS-TS-6 159,000 94,000 65,000

Burner Configuration (HLP) RFG-IR-W, RFG-IR RFG, RFG-W W-IR

Model

WS-TS-5 188,000 105,000 83,000

WS-TS-6 188,000 105,000 83,000

Colosso%Oven%Model!

W.C$.$(NG)!

BTU/hr'Input'(NG)!

W.C.$$(Propane)!

BTU/hr'Imput!

(propane)!

Colosso%%%%%%%%%%%%%%%%%65!

5’’!

50.000!

10’’!

65!

Colosso%%%%%%%%%%%%%%%%%80!

5’’!

55.000!

10’’!

80!

Colosso%%%%%%%%%%%%%%%100!

5’’!

55.000!

10’’!

100!

Colosso%%%%%%%%%%%%%%%120!

5’’!

55.000!

10’’!

120!

Colosso%%%%%%%%%%%%%%%%140!

5’’!

55.000!x"2!Burner!

10’’!

140!

Colosso%%%%%%%%%%%%%%%%160!

5’’!

55.000!x"2!Burner!

10’’!

160!

!

!!

!

GAS$SPECIFICATIONS$CONT!

Commercial#Oven#Series!

Installation,*Operation*&*Maintenance!

!Forno%Classico!

Forno Classico LLC

Phone: (805) 895-2626

53Aero Camino [email protected]

Goleta, CA 93117 USA www.fornoclassico.com

!

13!

This section covers all configurations of the Series Oven: Gas-Only models. Make certain you read the

appropriate section for your model.

The following are the manufacturer’s recommendations for venting the Forno Classico Commercial

Series ovens. It is never appropriate to use “B vent” in any part of an exhaust system connected to a

Forno Classico oven. All duct material must be manufactured to the specifications of a grease duct.

At least twice a month during the first two months of operation, to establish rate of creosote buildup and

necessary cleaning schedule. Typically, we recommend monthly cleaning for all solid fuel ovens. Submit

your venting plans to your local authorities before proceeding with your installation, as there may be

additional requirements in your area. There are two venting options:

VENTING OPTION 1

Direct Connection for Gas-Only Models (Colosso Gas Only): A listed building heating appliance chimney,

also listed as a grease duct as described in NFPA 96, connected directly to the oven flue collar, Forno

Classico does not recommend the use of an in-line fan. A field built grease duct, constructed and

installed to the specifications of a grease duct as detailed in NFPA 96 or the International Mechanical

Code, may also be used.

!

!!

!

VENTING!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino [email protected]

Goleta, CA 93117 USA www.fornoclassico.com

!

14!

VENTING OPTION 2

A Listed Type 1 exhaust hood or one that is constructed and installed in accordance with all relevant local

and national codes. Note that the notch of the hood is even with the front edge of the oven. The hood

should be installed in accordance with the hood manufacturer’s instructions, and with the Standard for

Ventilation Control and Fire Protection of Commercial Cooking Operations, NFPA 96 and/or the applicable

local and national codes. Solid fuel burning ovens must be vented separately from non-solid fuel burning

equipment.

It is never appropriate to use “B vent” in any part of an exhaust system connected to a Forno Classico

Oven

. All duct material must be manufactured to the specifications of a grease duct. Due to the possibility

of sparks entering the duct, exhaust systems serving solid fuel equipment MUST not be combined with

exhaust systems serving other (non-solid fuel) equipment. This model is rated as solid fuel equipment and

must be vented as such.

VERY IMPORTANT!

FORNO CLASSICO RECOMMENDS THAT YOU CONSULT WITH A QUALIFIED MECHANICAL

ENGINEER AND SUBMIT YOUR VENTING PLANS TO LOCAL CODE AUTHORITIES

BEFORE PROCEEDING WITH INSTALLATION.

FIRE SUPPRESSION

Check with your local code officials to see if fire suppression is required in your area. If fire suppression is

required, you must vent the oven using a Listed Type 1 Exhaust Hood constructed and installed in

accordance with NFPA 96. If fire suppression is required, Forno Classico recommends providing

protection for the hood duct collar and plenum. The fusible link in the hood must be rated at 450 °F

minimum. All installations are subject to the approval of the local authority having jurisdiction.

!!

!

VENTING!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino info@fornoclassico.com

Goleta, CA 93117 USA www.fornoclassico.com

!

15!

SEEK OUT A QUALIFIED PROVESSIONAL TO DESIGN AND INSTALL

YOUR VENTING SYSTEM. CHECK WITH LOCAL AUTHORITIES FOR

SPECIC CODE REQUIRMENTS.

!!

!

VENTING'CONT.!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino info@fornoclassico.com

Goleta, CA 93117 USA www.fornoclassico.com

!

16!

!!

!

LIGHTING'THE'OVEN!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino [email protected]

Goleta, CA 93117 USA www.fornoclassico.com

!

17!

!!

!

LIGHTING'THE'OVEN!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino [email protected]

Goleta, CA 93117 USA www.fornoclassico.com

!

18!

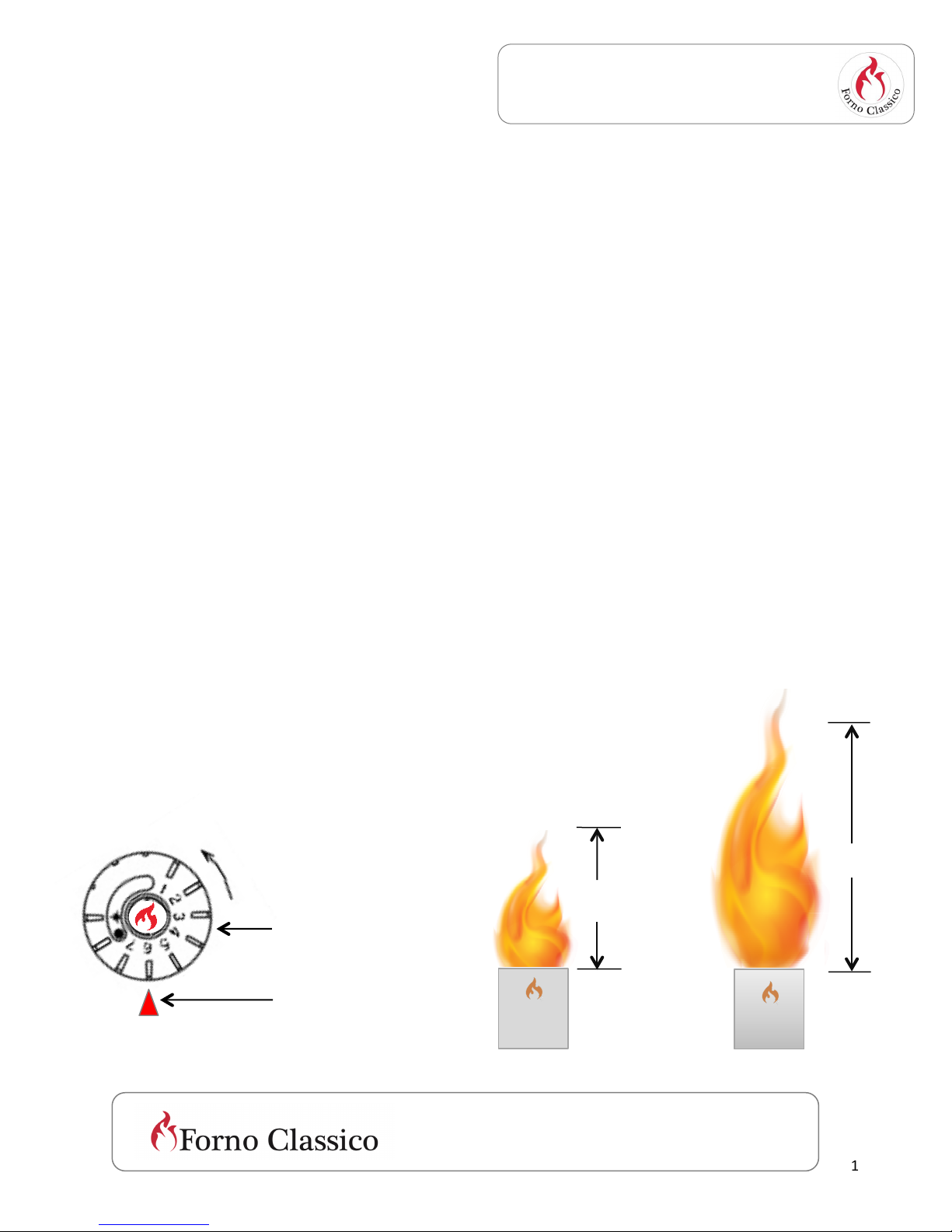

8’’!

15’’!

For each specific configuration of oven there is a system that determines what the desired flame

height will be. Each flame height corresponds to a saturated floor temperature. Several factors

need to be accounted for in order to determine this relationship for each oven. Burning wood

simultaneously in the oven will influence the settings below.

USING THE FLAME HEIGHT INDICATOR SCALE

Heat Up Flame: Set Throttle Knob Pointer at “5” (highest setting) on the Flame Height Index Scale

until desired temperature is reached.

Holding Flame: Set the flame height to “3” (~8–9" flame) on the Flame Height Index Scale for

desired temperature of 570–600 °F. Set the flame height to “2” (~5–6" flame) on the Flame Height

Index Scale for desired temperature of 450–480 °F.

Cooking Flame: After introducing the pizza/product into the oven, visually raise the flame to

approximately 3inches higher than the Holding Flame.

Return the Flame Height Control Knob to the Holding Flame position after removing the

pizza/product from the oven.

THE COOKING FLAME HAS TWO PURPOSES:

1. To bake the top of the pizza/product as fast as the bottom of the pizza/product. 2. To help

replace heat to the floor (hearth) that is lost during production cooking.

Note: The settings recommended on the Flame Height Index Scale for specific flames are based on

ovens that have been installed according to specifications. Individual results may vary slightly.

Flame Height Control Knob

FLAME HEIGHT INDICATOR

Comprised of two parts

Flame Height Index Scale

!!

!

FLAME&CONTROL&&&&&&&&&&&&&&&

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino info@fornoclassico.com

Goleta, CA 93117 USA www.fornoclassico.com

!

19!

CLEANING THE OVEN

Clean as needed—multiple times per hour depending on production. Forno Classico

recommends the use of long-handled brushes for sweeping up surface debris that will

accumulate on the floor of the oven during use. Use a natural fiber brush, always brushing away

from the radiant burner well to the doorway where it can be easily removed with a dough cutter or

spatula. For deeper cleaning, use a brass bristled brush. The oven floor can be then cleaned with

a damp (not wet) rag wrapped around the brush head.

Forno Classico offers an assortment of oven brushes available through your dealer. Specification

sheets may be viewed on the Forno Classico website under Tools & Accessories.

NEVER PLACE ANYTHING IN OR ABOVE THE RADIANT FLAME.

NEVER SWEEP DEBRIS INTO THE RADIANT BURNER. THIS CAN CAUSE THE BURNER TO

CUT OUT, DAMAGE BURNER COMPONENTS, AND/OR EFFECT BURNER PERFORMANCE.

PROBLEMS CAUSED BY DEBRIS IN THE RADIANT BURNER WILL NOT BE COVERED BY THE

OVEN WARRANTY.

NEVER USE ICE, EXCESSIVE WATER, ANY LIQUID, OR ANY TYPE OF CLEANING CHEMICAL

ON THE OVEN FLOOR. DOING SO CAN SEVERELY DAMAGE THE OVEN CERAMIC AND THIS

DAMAGE WILL NOT BE COVERED UNDER WARRANTY.

NIGHT HEAT RETENTION DOORS

The Night Heat Retention Door(s) are used for nighttime heat retention.

Do not operate the oven with doors in place.

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino [email protected]

Goleta, CA 93117 USA www.fornoclassico.com

!!

!

GAS$OVEN$MAINTENACE$$$$$$

Commercial#Oven#Series!

Installation,*Operation*&*Maintenance!

!

20!

DAY$1!

DAY$2!

DAY$3!

DAY$4!

6’’

10’’

15’’

PILOT

!!

!

CURING'THE'OVEN'!

Commercial*Oven*Series!

Installation,*Operation*&*Maintenance!

Forno Classico LLC

Phone: (805) 895-2626

53 Aero Camino [email protected]

Goleta, CA 93117 USA www.fornoclassico.com

This manual suits for next models

5

Table of contents

Other Forno Classico Kitchen Appliance manuals