Forster Products 010631 User manual

User Instructions for the Bench Rest®Powder Measure

Issue 3

1.0 GENERAL INFORMATION

The Bench Rest Powder Measure keeps your powder flowing

evenly. Its long, narrow, powder-charge reservoir minimizes the

amount of powder shearing for each and every charge.

The vernier scale on the charge arm lets you control minute

changes in capacity. The charge arm meters the powder and

dispenses a flow of consistent charges using your choice of gun

powder. For example, it will measure from 2½ grains of Bullseye®

to 95 grains of IMR®4320 or Alliant Reloder®15.

The powder hopper is designed to eliminate variation in charges

due to changes in the volume of powder contained in the hopper.

The small outlet on the hopper serves as a built-in baffle,

regulating the powder leaving the hopper and entering the

measure in a uniform manner.

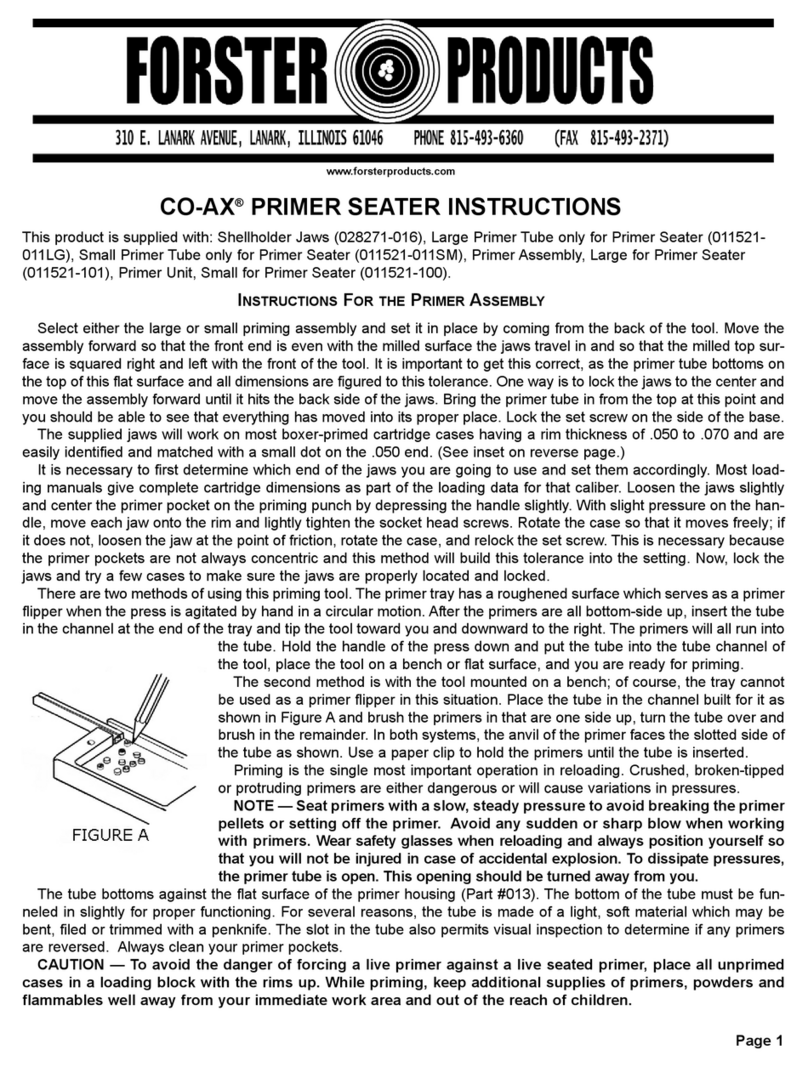

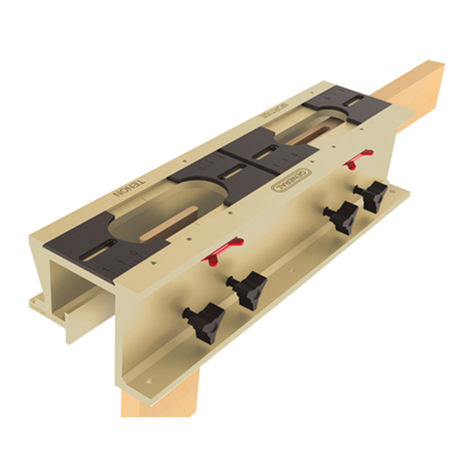

Figure 1. Powder Measure Overview

2.0 SAFETY INFORMATION

Please follow all pertinent safety procedures such as

wearing safety glasses, being in a well-lit and well-ventilated

workspace, and having all reloading tools in top working

condition and no flames, sparks or static electricity.

Always follow instructions and tables from a reliable

reloading manual to determine proper powders, bullet

weights, and primer types.

3.0 INSTALLATION

3.1 Assembly

The Powder Measure is shipped to customers fully assembled.

To begin measuring,

1. Mount the device to your workstation, as described below.

2. Load the Powder Hopper and Cover into the top of the Body

Casting (Fig. 1).

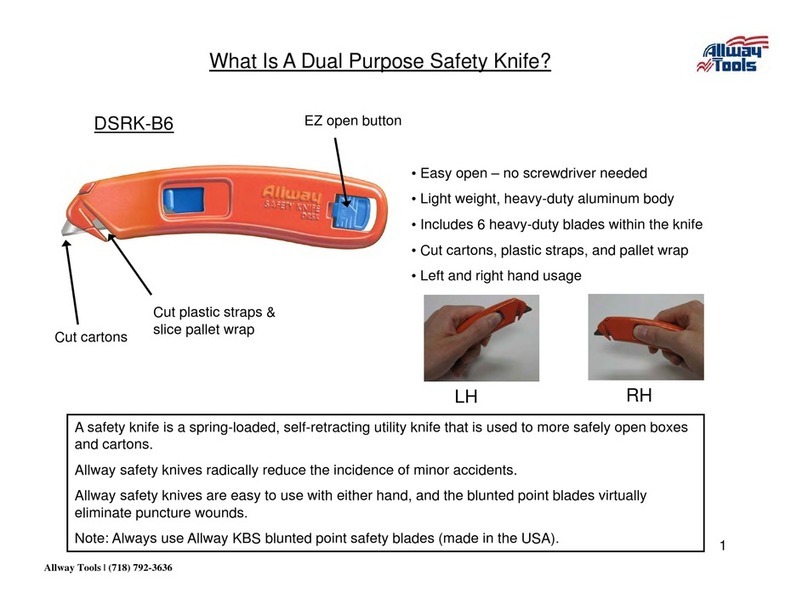

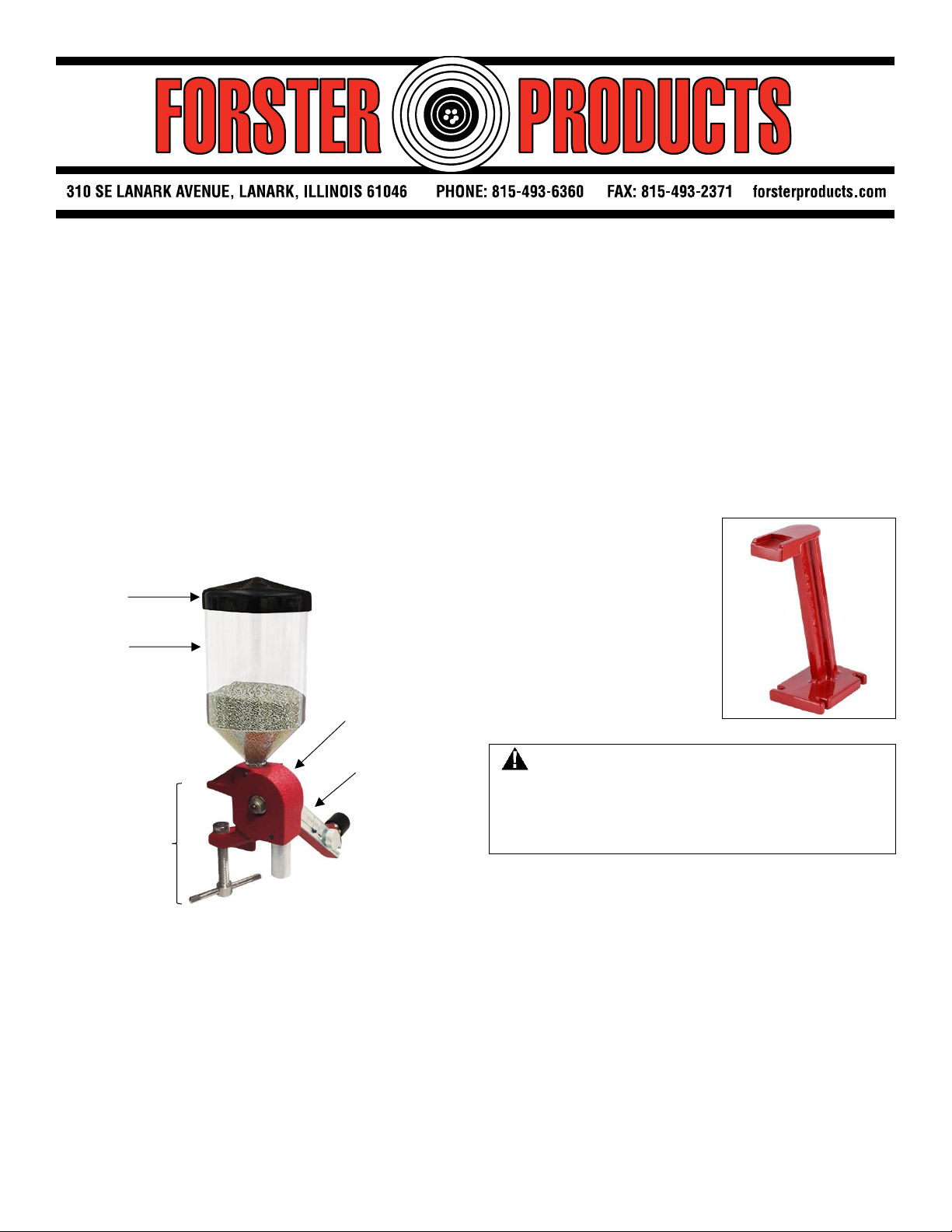

3. Check to see that the Locknut (010631-021) on the Cross

Bolt (010631-026) is tight. This will serve to remove any

excess play between the iron castings (Fig. 3).

4. Secure the Drop Tube (010631-027xx) lightly with the Set

Screw (010631-013).

3.2 Mounting

Three methods are available for securing the Powder Measure to

different work surfaces.

3.2.1. Clamp to Table Edge or Board

The C-clamp (Fig. 1) opens to

receive boards up to 1¼" wide.

3.2.2. Screw to Workbench or

Board

The top of the C-clamp casting

contains a hole for a woodscrew.

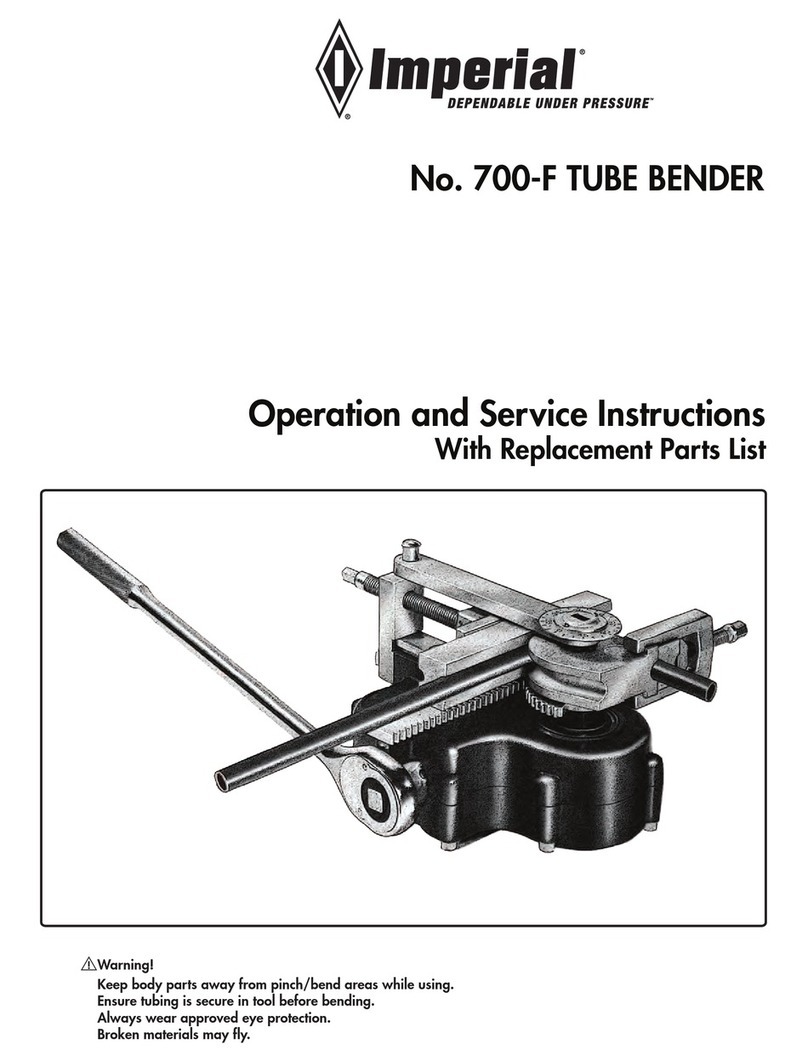

3.2.3. Clamp to Optional Powder

Measure Stand

The Bench Rest Powder

Measure Stand (017941)

securely holds the Powder

Measure in place. See Fig. 2.

4.0 PROCEDURE

WARNING

PERSONAL INJURY

Only use smokeless gun powder in the Powder Measure.

Never mix powders.

Failure to comply with these instructions could result in

death or serious injury.

To initialize the charge chamber for a specific volume of powder,

1. First, make sure that the internal powder-flow channels are

thoroughly cleaned of any residue from previous usage.

2. Loosen the Thumbscrew (010631-022) on the Charge Arm,

in order to drop the Charge Bar (010631-024) to its inner

position. Tighten the Thumbscrew.

(The Charge Bar has two settings –inserting the

Thumbscrew into the “outer”hole allows it to hold charges of

approximately 2 to 37 grains of powder, and in the “inner”

hole approximately 37 to 95 grains [see Fig. 3 for the

Thumbscrew setting positions on the Charge Bar].)

This step assumes that you need to reset to the lower “outer”

amount; otherwise, proceed to step 3.

3. With the Charge Arm handle in the down position (at

6 o’clock, when facing the Arm), pour the desired weight of

powder from your scale pan into the empty Hopper (010631-

025). The powder will flow into the Charge Arm.

Figure 2. Optional Stand

Cover

(010631-025-LID)

Iron Body Casting

C-Clamp for

mounting to

reloading bench

Iron Charge Arm

with Vernier Scale

Hopper

(010631-025)

WARRANTY

All Forster Products are warranted against defects in materials and workmanship for the life of the product. Parts excluded from the warranty are those

that, by nature of their function, are subject to normal wear (such as springs, pins, etc.) or that have been altered, abused, or neglected. If the product

is deemed defective by workmanship or materials, it will be repaired, reconditioned or replaced (at Forster’s option). This warranty supersedes all other

warranties for Forster Products, whether written or oral.

forsterproducts.com

010631-001 Issue 3, March 2020

4. Rotate the handle 90° toward you to the neutral position, so

that the Thumbscrew and scale are horizontal to the work

surface (at 9 o’clock).

5. While the Arm is in the neutral position (that is, neither fully

up, filling, nor fully down, dispensing), slowly move the

Charge Bar toward the powder charge until it stops, and lock

in place with the Thumbscrew.

6. Fully lift up the Charge Arm handle (to 12 o’clock) to allow

the powder charge to flow out through the Drop Tube.

7. The Charge Arm/Charge Bar should now be adjusted to the

volume of powder corresponding to the sample charge you

weighed into the Powder Measure. Load your powder into

the Hopper and throw a few charges, weighing each one to

verify accuracy. If needed, make slight adjustments with your

Charge Bar to fine tune.

The Charge Arm is now adjusted for a selected volume. Fill the

Hopper and verify the next 2-3 charges by weighing them. If

necessary, adjust the Charge Bar. The Powder Measure is ready

to charge all your cases. You should be able to throw a charge

every 4 seconds.

4.1 Tips for Effective, Repeatable Measurement

To get acquainted with your Powder Measure, throw several

charges with a given powder and setting. Check each one

on an accurate scale.

Your hand motion needs to be consistent and deliberate.

Practice by moving the handle with a slow, steady downward

movement. Try this experiment: Throw three charges with a

slow and steady movement through the entire 180° and let

the handle stop firmly. Repeat, but use a swift down

movement of the handle –this time, you should find the

charge smaller by ½ grain or more.

The Powder Measure will throw up to 95 grains of smokeless

gun powder. For larger charges, set the volume to half the

total and throw two charges.

Some users find a better feel and more consistent handle

throw by “choking up”on the Arm Casting (010631-015) as

opposed to using the Knob (CT1010-021).

If a coarse grain of powder shears, back up a very small

amount and clear the cutoff.

Visually inspect the cases for unintended double charges by

inspecting them in a loading block.

It is important to remember that charge volumes can vary

from day to day, depending on temperature, humidity, static,

and the type of powder used. For cases of the same caliber,

it is best to verify the powder’s weight and volume in the

empty cartridge, at least at the start of the day’s handloading

5.0 MAINTENANCE

Assure the Locknut (010631-021) stays tight to the Cross

Bolt (010631-026) as the powder should never accumulate

between the machined Powder Measure surfaces.

It is not necessary to remove your Powder Measure from the

bench in order to empty the Hopper (010631-025). Lift the

handle 90°, remove the Charge Bar (010631-024), set the

powder can under the opening in the Handle, and lower the

Handle. Powder will drain from the hopper.

6.0 ORDERING INFORMATION

Order Number

Description

010631

Bench Rest Powder Measure

017941

Bench Rest Powder Measure Stand (optional)

To find a Reseller, go to forsterproducts.com and click

Distributors. If your distributor cannot supply you, or if you need

parts, please contact Forster Products directly by email, phone,

or fax.

Figure 3. Powder Measure Exploded Drawing

Cover

(010631-025-LID)

Set Screws, x 2

(010631-013)

Locknut

(010631-021)

9/32" x 5/8"

Washer

(010631-020)Body Casting

(010631-011)

Small or Large Hole

Drop Tube

(010631-027SM/

010631-027LG)

–or –

Long Drop Tube

(011051)C-Clamp with Screw

Washer & Swivel

(010631-012)

Crossbolt

(010631-026)

1/8" x 1/4" Steel

Roll Expansion Pin

(010631-016)

Thumbscrew

(010631-022)

Slide Rule

(010631-018)

Vernier Sticker

(010631-017)

Charge Bar

(010631-024)

Knob

(CT1010-021)

Knob Screw

(CT1010-022)

Arm Casting

(010631-015)

OuterCharge

Bar Setting

InnerCharge

Bar Setting

Hopper

(010631-025)

This manual suits for next models

1

Other Forster Products Tools manuals