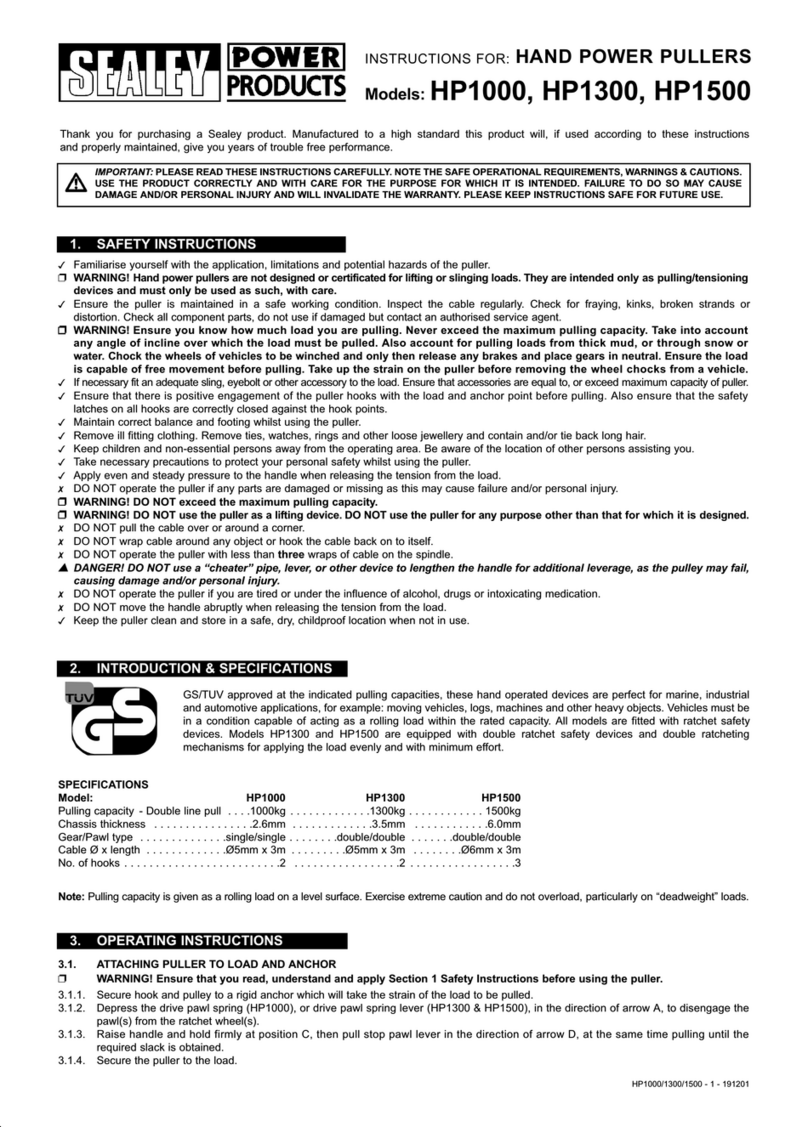

1. SAFETY INSTRUCTIONS

3. OPERATION

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

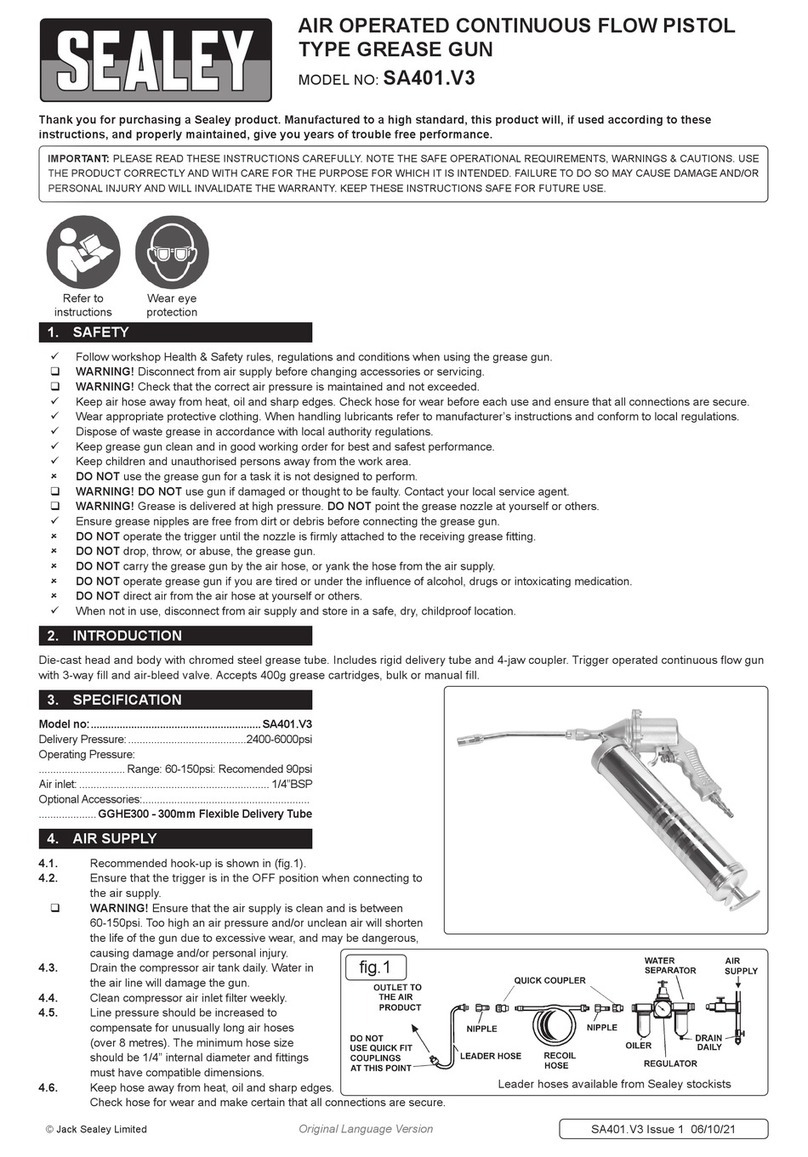

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE

PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL

INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1.1. GENERAL SAFETY

WARNING! Ensure Health & Safety, local

authority, and general workshop practice

regulations are adhered to when using this

equipment.

Familiarise yourself with the application and

limitations of the panel bag set, as well as

the potential hazards.

Maintain the set in good condition.

Replace damaged parts.

Use genuine parts only. Unauthorised parts

may be dangerous and will invalidate the

warranty.

Maintain correct balance and footing. Ensure

floor is not slippery and wear non-slip shoes.

Keep children and unauthorised persons

away from the working area.

DO NOT put hands/fingers in apertures

created by bags without first inserting a

mechanical chock to prevent accidental

injury.

DO NOT use the panel bags for purposes

other than those for which they were

designed.

DO NOT over-inflate.

DO NOT use on doors fitted with air bags.

DO NOT use when you are tired, under the

influence of alcohol, drugs or intoxicating

medication.

Deflate bag prior to storage.

Clean, dry and store in supplied bag.

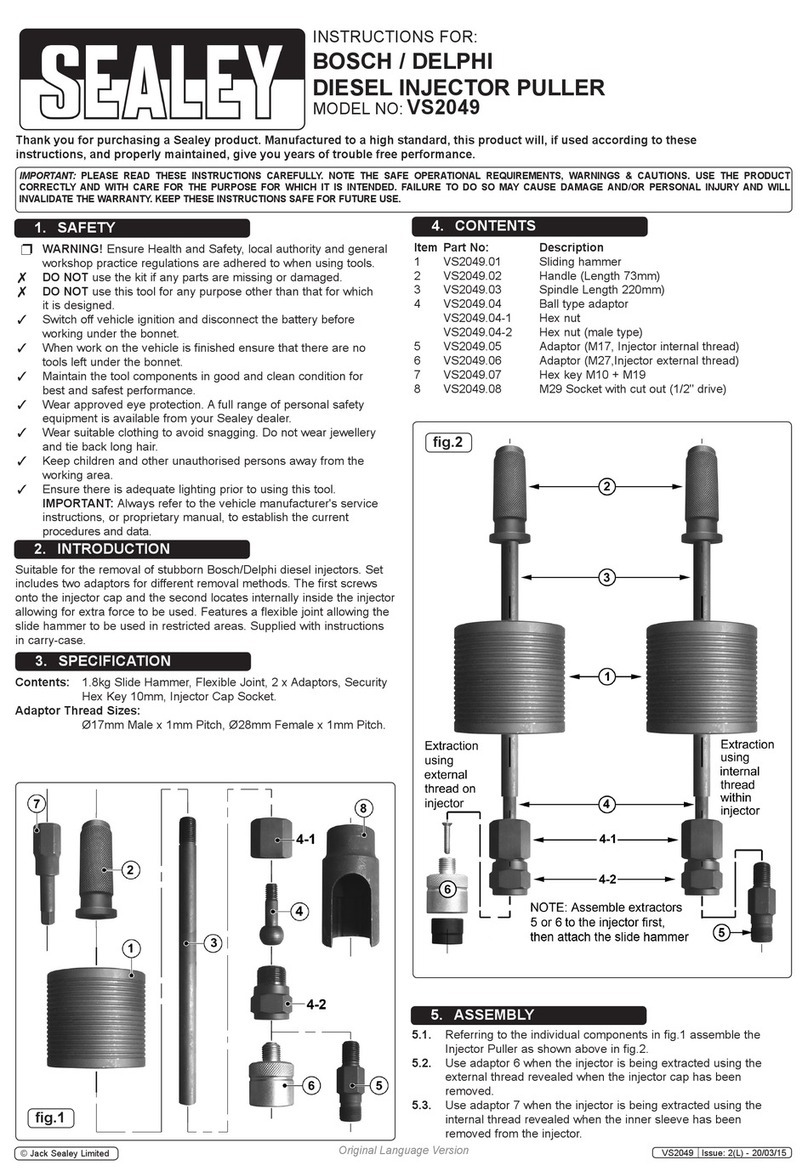

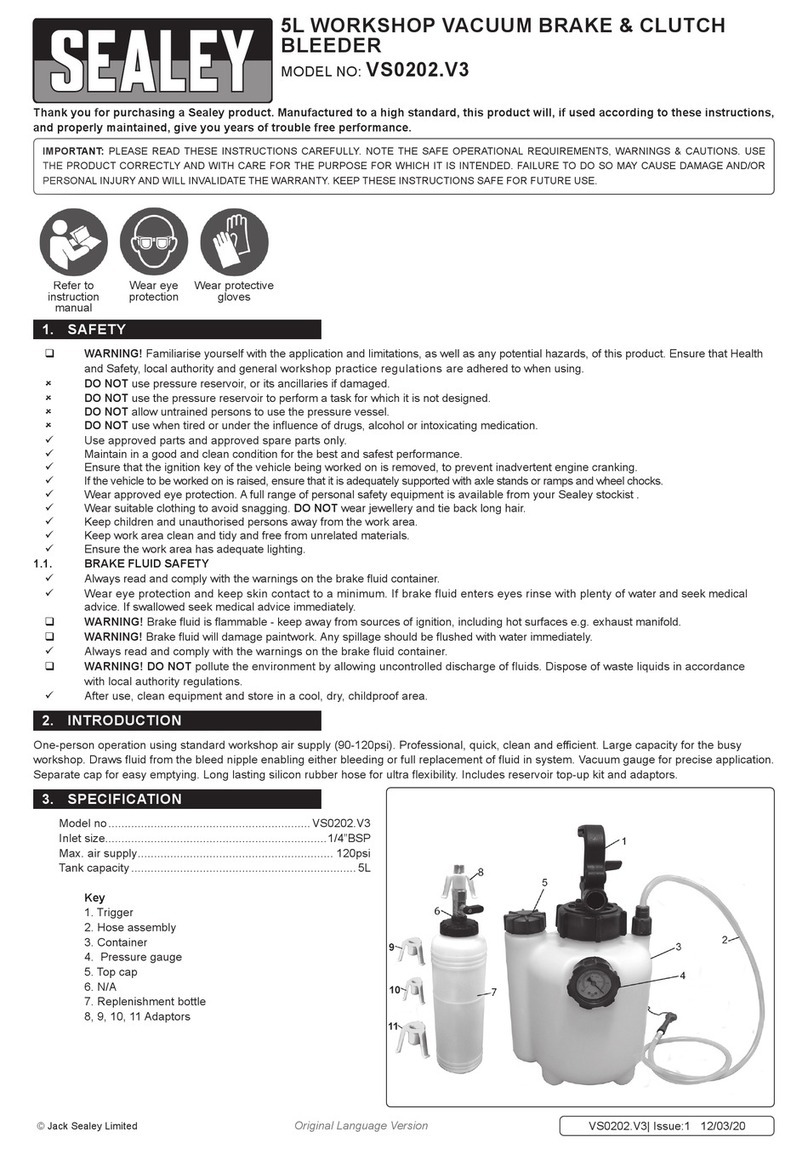

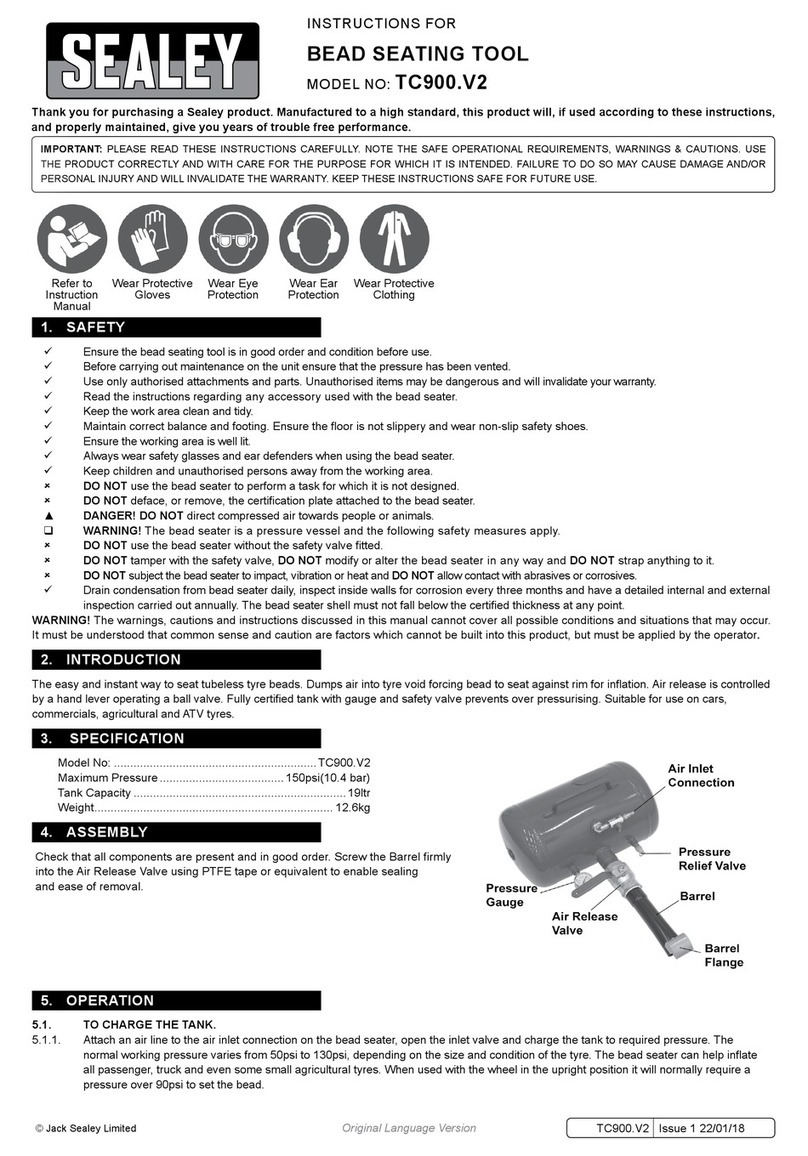

Multi-purpose durable air cushion devices with

rigid edges and fine control air valve. Suitable

for positioning panels, bonnets and boots, prior

to fitment. A 2mm bag thickness and semi-rigid

construction allows bags to be slid between

door frames and weather-stripping for improved

access for emergency vehicle opening tools.

Soft air cushion is gentle on paintwork, frame,

beadings and glass. Supplied in a vinyl pouch.

3.1. TO ADJUST BODY PANELS.

3.1.1. Place a panel air bag between the vehicle

body and panel to be fitted (bonnet, boot

etc.) at the point that needs adjusting.

3.1.2. Attach the pump to the bag valve, ensure

the pump valve is closed

(fully clock-wise).

3.1.3. Pump air into the bag by squeezing the

bulb on the pump, (taking care not to

over-inflate) moving the panel to the

required position.

3.1.4. If you need to reposition the panel in

more than one place you can disconnect

the pump from the first bag by pushing

the thumb lever on the pump adaptor and

withdrawing it from the bag valve leaving

the bag inflated, in order to insert and

inflate another bag.

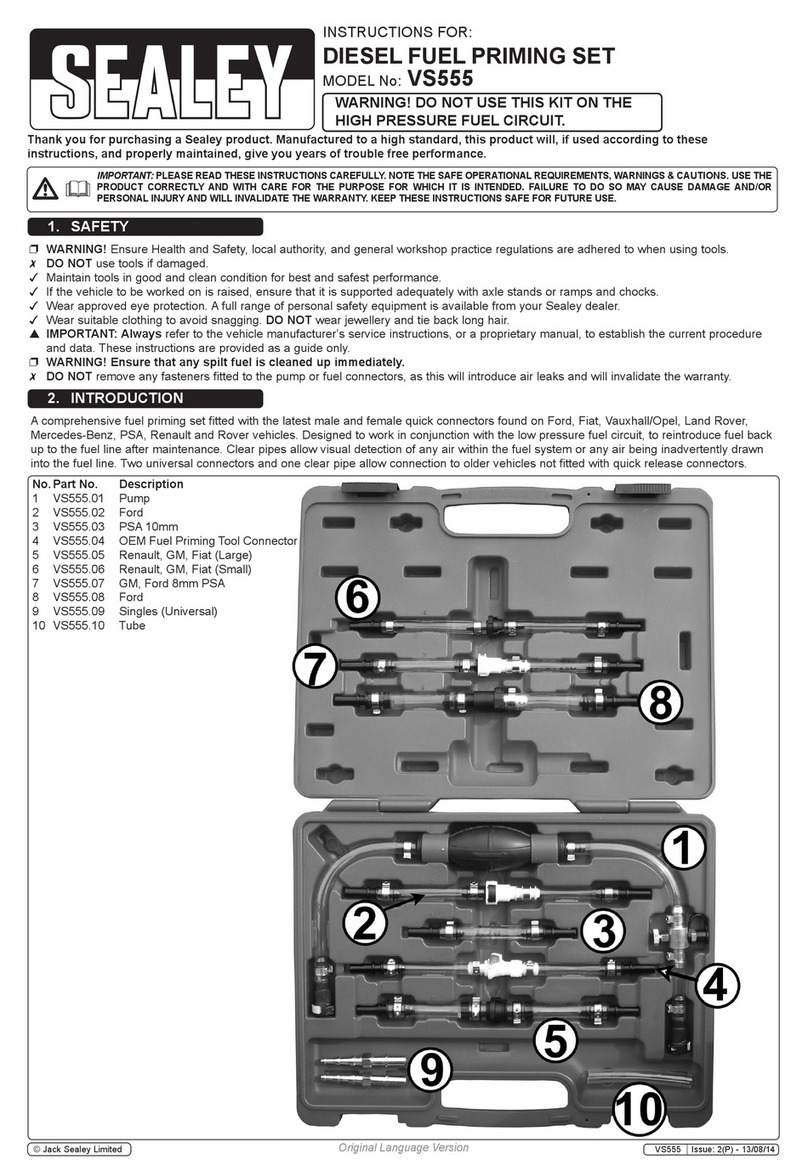

2. INTRODUCTION & SPECIFICATIONS

INSTRUCTION MANUAL FOR:

Panel Bag Set 3pc

MODEL No: VS911.V2

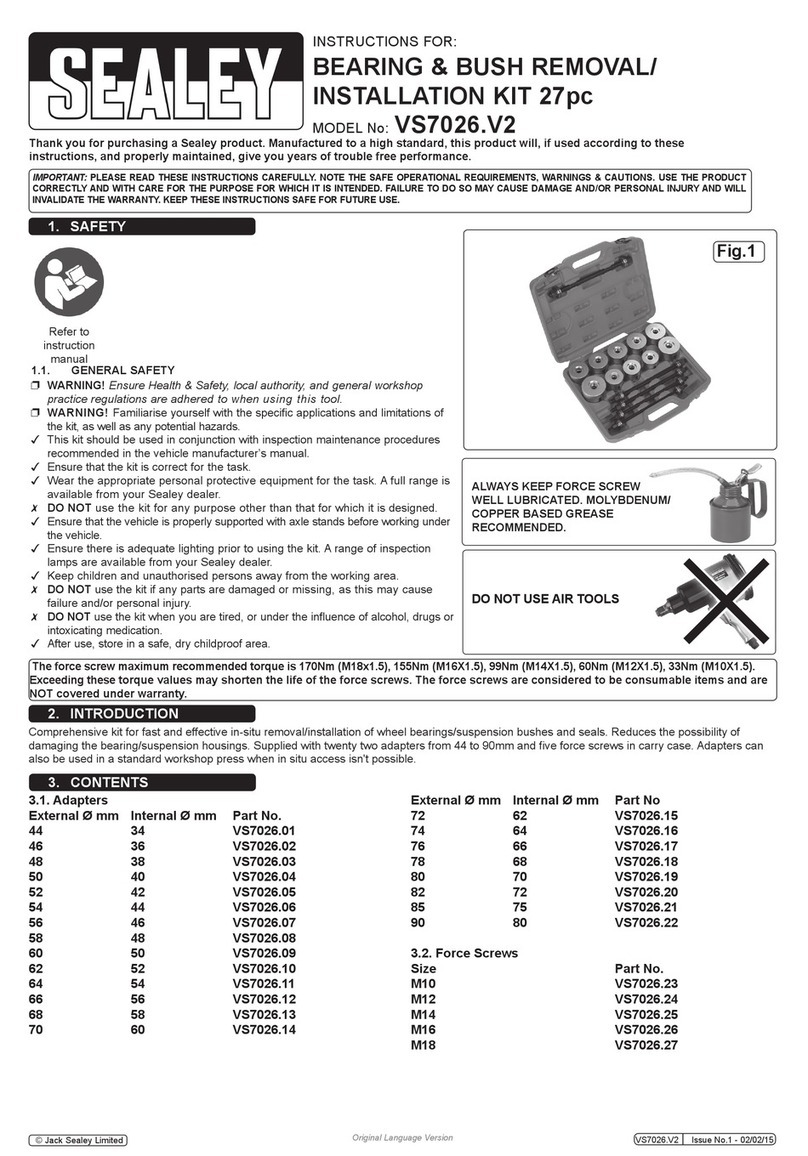

Model .........................VS911.V2

LoadCapacity: ......................... 100kg

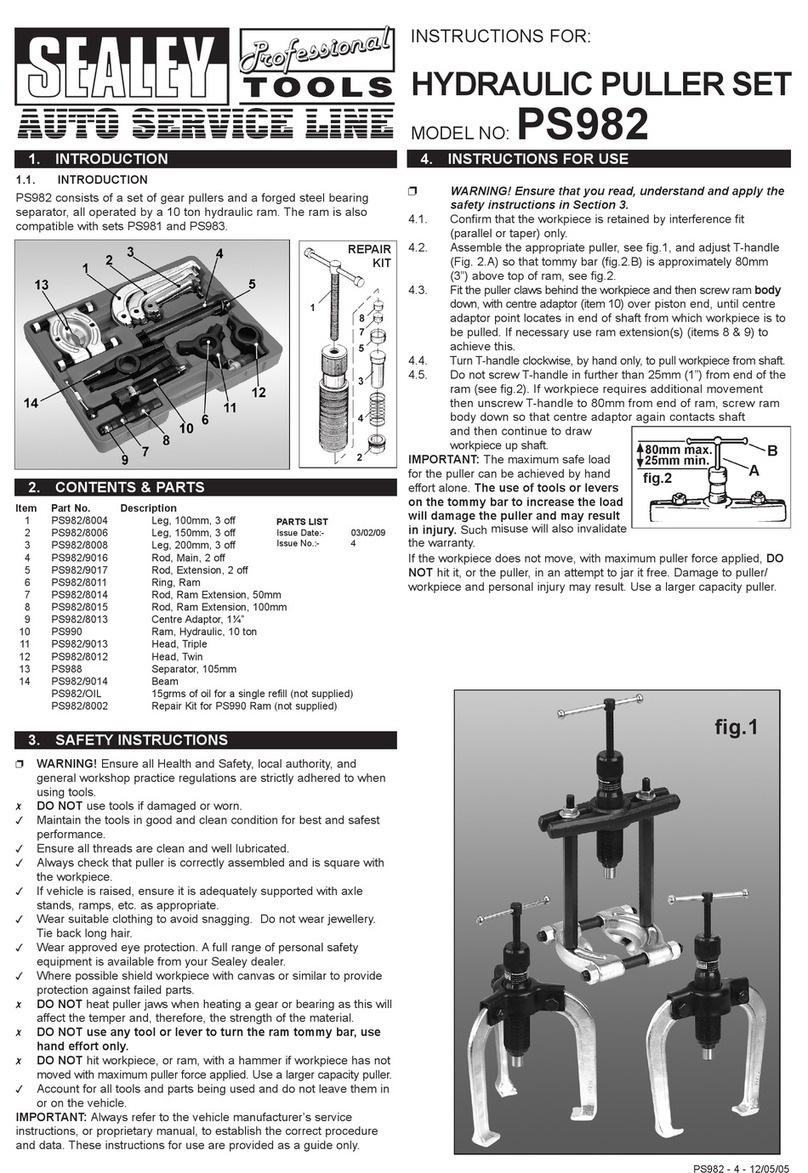

Bag Dimensions (W x H): . . . . . . . . . . . . Refer to fig.1

Bag1: ........................... 40x182mm

Bag2: ........................... 57x188mm

Bag3: .......................... 160x160mm

Original Language Version VS911.V2 Issue: 1 - 22/08/11

g.1