l. If the tension yoke (5) was disassembled for replacement

of parts, place the bend indicating (dial) plate (4) on the

sleeve bearing (3) and press the sleeve bearing into the hole

at the end of the tension yoke (5), leaving just enough

clearance between the flange of the sleeve bearing (3) and

plate (4) to permit the dial to rotate without interference.

Attach the cap (2) with the two screws (1). Attach the

tension yoke (5) to the screw post (20) with the screw (6).

m. If the name plate (26) was removed, install a new name

plate with the two drive screws (27).

n. If a new clamp block pressure pad (10) was required,

attach it to the end of the clamp yoke screw (11) with the

screw (9). Leave the screw (9) loose enough to permit the

screw (11) to rotate.

o. If any of the sector gears were removed from their

respective form block assemblies (7), attach them by

installing new pins. Alignment of splines in the sector gear

and form block can be assured if the correct size drive shaft

(31) is inserted temporarily through the splines of both parts

before pressing the pins into position.

28. TESTING AFTER OVERHAUL.

a. After reassembly has been completed, perform bending

operations on several sizes and types of tubing to make sure

that the machine is operating properly. If any trouble is

encountered, it must be remedied and the machine

rechecked before placing it in storage or putting it into

operation.

b. Bends performed after overhaul must be unmarred, free

of kinks, wrinkles and surface imperfections. All bends made

in like material must be uniform, and the reduction in

cross-sectional diameter (flatness across throat) at any point

in the bend must not exceed five percent of the original

diameter of the tube.

c. If the tube bender passes these tests satisfactorily, it is

ready to be stored or placed into service.

SECTION II

REPLACEMENT PARTS LIST

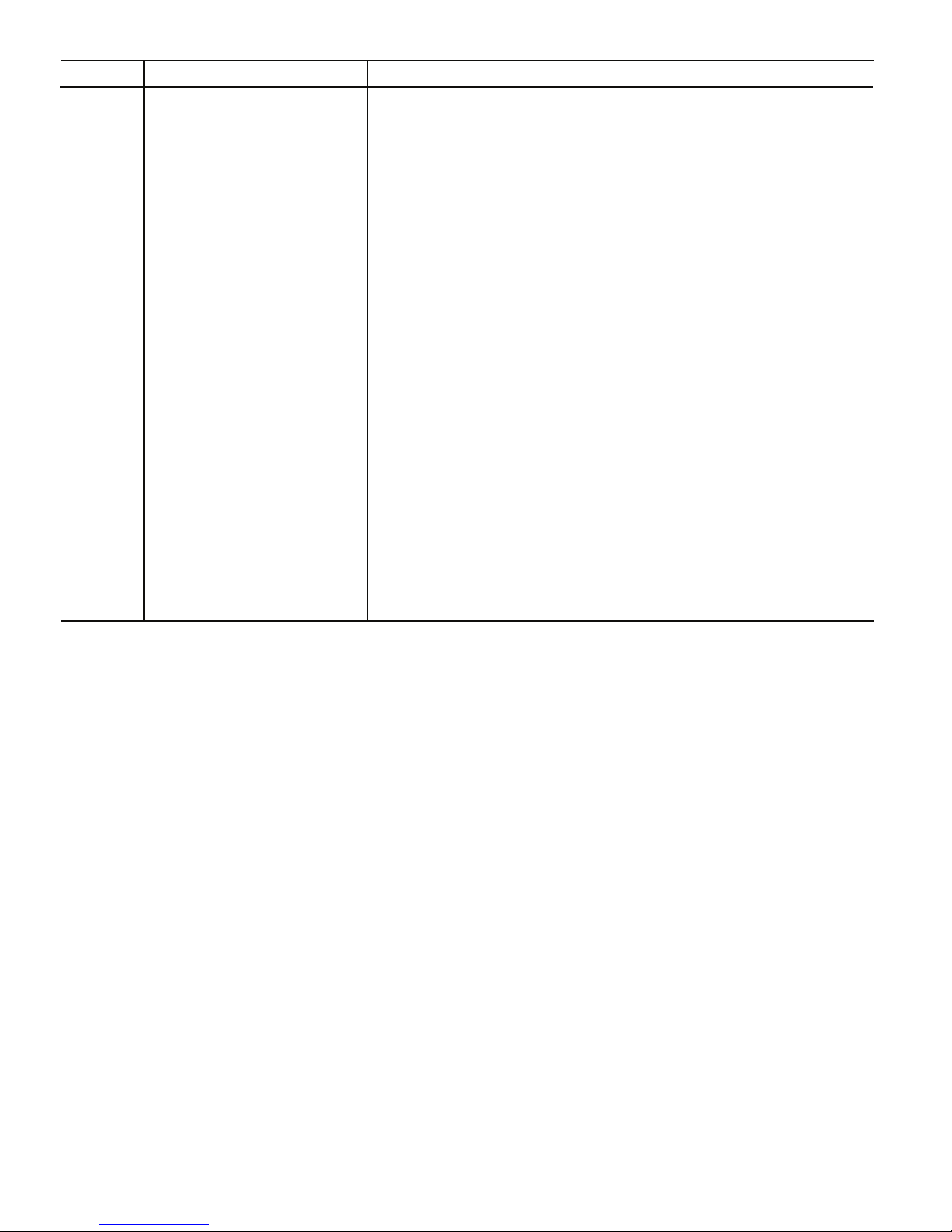

Figure

and

Index

No.

Imperial

Part No. Part Description Qty.

Figure

and

Index

No.

Imperial

Part No. Part Description Qty.

12-

-1

-2

-3

-4

-5

-6

-7

-7

-7

-7

-7

-7

-8

-8

-8

-9

-10

-11

-12

-13

-13

-13

-14

-15

-16

-17

74597

74559

74560

74558

74557

74596

74569

74572

74575

74578

74581

74584

74587

74588

74589

74604

74593

74592

74591

74566

74567

74568

74565

74564

74600

74599

SCREW, No. 2 - 56x1/2".......

CAP ......................................

BUSHING .............................

PLATE ...................................

BAR .....................................

SCREW, 1/4-20x5/16".........

BLOCK GEAR ASSY.

(1/4") ..............................

BLOCK GEAR ASSY.

(5/16") ............................

BLOCK GEAR ASSY.

(3/8") ..............................

BLOCK GEAR ASSY.

(1/2") ..............................

BLOCK GEAR ASSY.

(5/8") ..............................

BLOCK GEAR ASSY.

(3/4") ..............................

BLOCK (1/4 & 5/16")...........

BLOCK (3/8 & 1/2") .............

BLOCK (5/8 & 3/4") .............

SCREW, No. 6 - 32x1/2" ......

PAD .....................................

SCREW ................................

YOKE ...................................

FORM SHOE (1/4 & 5/16")...

FORM SHOE (3/8 & 1/2") ....

FORM SHOE (5/8 & 3/4") ....

RACK ...................................

PRESSURE PLATE ...................

SCREW, No. 8 - 32x3/8" ......

DRIVE PIN ............................

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

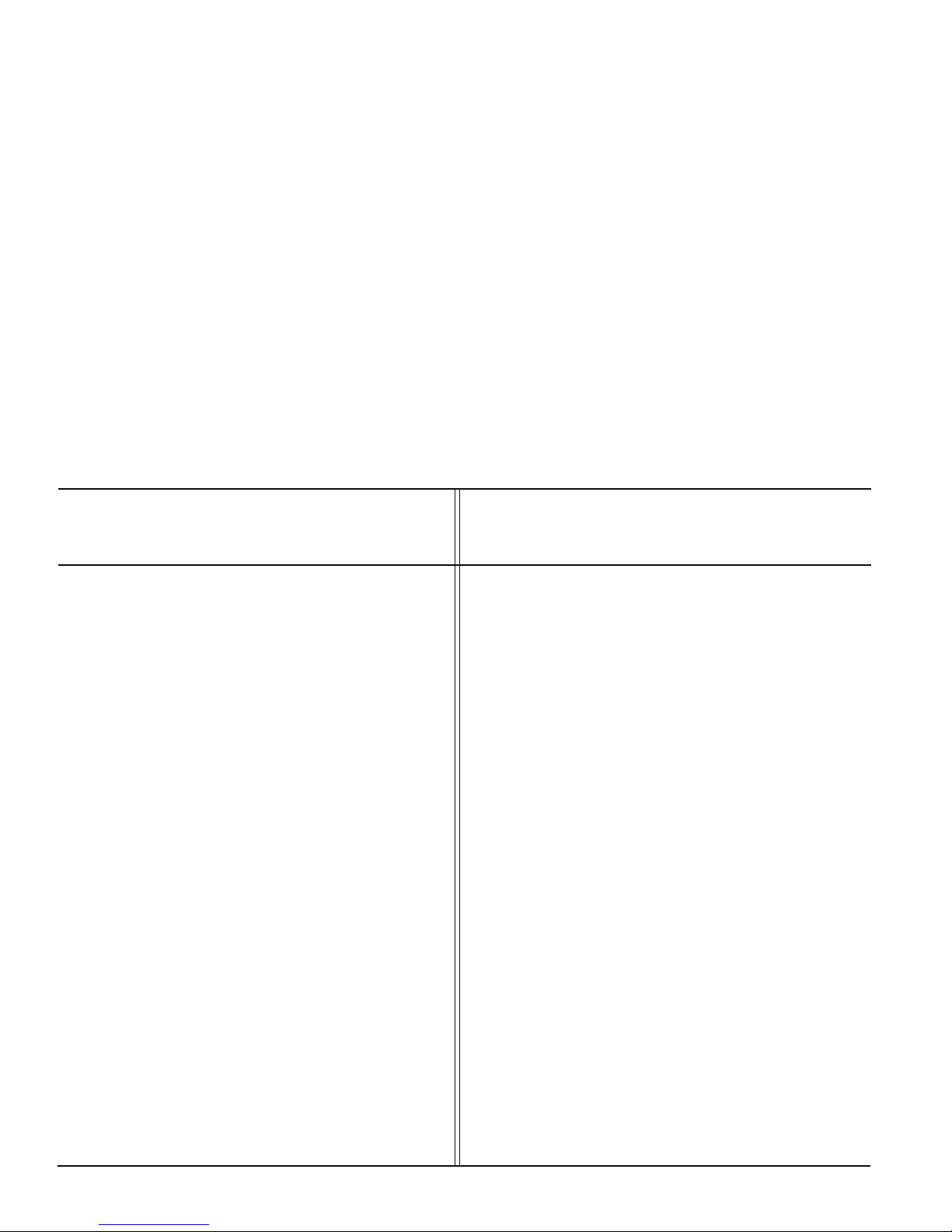

12-

-18

-19

-20

-21

-22

-23

-24

-25

-26

-27

-28

-29

-30

-31

-31

-32

-33

-34

-35

-36

-37

-38

-39

-40

-41

-42

-43

-44

-45

-46

-47

74562

74563

74556

74594

74595

74543

74561

74598

74532

74601

74541

61252

28843

74554

74555

74553

74550

74549

74546

74548

74552

68089

74545

74551

74547

74608

74544

74542

74609

74603

79321-01

SCREW ................................

BLOCK .................................

POST....................................

SCREW, 1/2 - 13x1-1/4" .....

LOCKWASHER .....................

BALL BEARING .....................

SUPPORT ..............................

SCREW, 3/8 - 16x3/4" ........

NAMEPLATE .........................

DRIVE SCREW, No. 4 x 5/16"...

HOUSING UPPER HALF .........

SOCKET HEAD SCREW,

1/4 - 20x1-1/4"...............

LOCKWASHER .....................

SHAFT (1/4") .......................

SHAFT (5/16 - 3/4").............

GEAR ...................................

BUSHING .............................

SPACER ................................

GEAR ...................................

KEY ....................................

COUNTER SHAFT .................

PIN ......................................

BALL BEARING .....................

SPACER ................................

SHAFT ..................................

RATCHET WRENCH ..............

BALL BEARING .....................

HOUSING LOWER HALF .......

WRENCH .............................

CARRYING CASE ASSY ........

SOCKET WRENCH

2

1

1

1

1

1

1

2

1

2

1

8

8

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

10