FORSTRONG FH-6300 User manual

PAGE 1

2 1

rooDfoediSlluProoDfoediSlluP

rooDfoediShsuProoDfoediShsuP

THIS IS A LEFT HAND DOOR THIS IS A RIGHT HAND DOOR

CLOSING SPEED

LATCHING

SPEED

CLOSING

VALVE

LATCH

VALVE

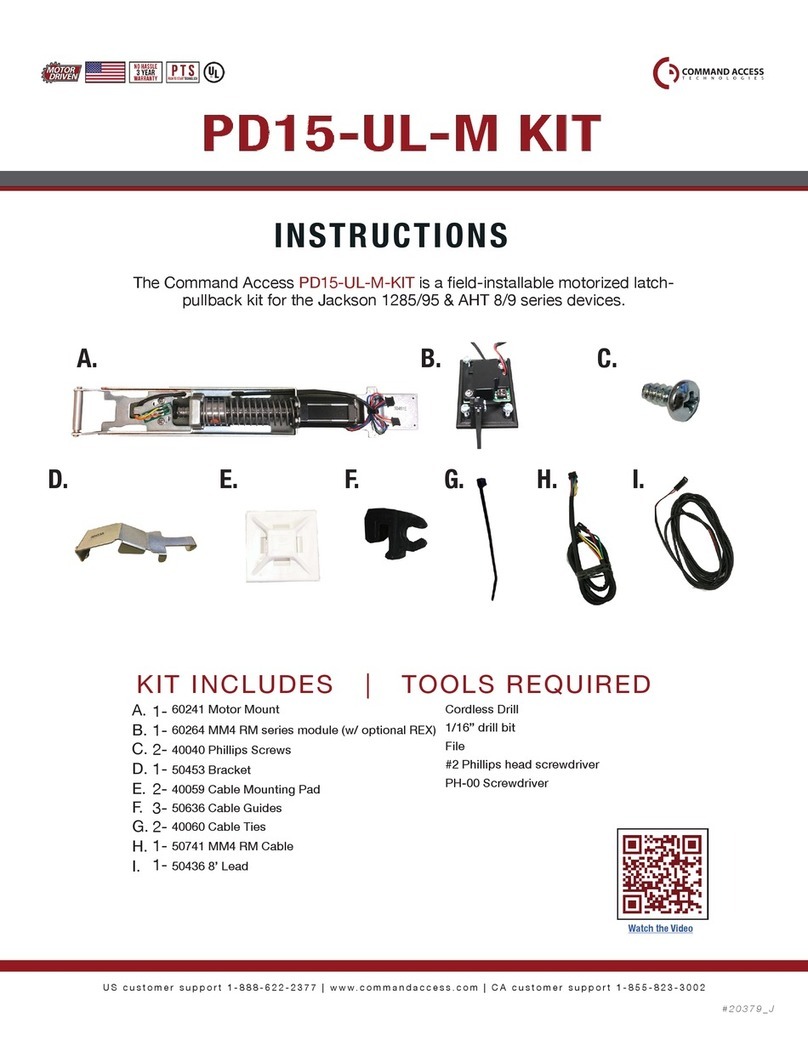

Regular Arm Installation

Closer installs on PULL/HINGE

side of door

DOOR CLOSER ADJUSTMENTS

NOTE :Closing arcs("CLOSE"and"LATCH") are controlled by two(2)separate speed adjusting valves.

Adjust the CLOSING speed a rst and then adjust the LATCHING speed.

1. "CLOSING"speed adjustment is accomplished by full rotations of the speed adjusting valve.

-Turn the speed adjusting valve CLOCKWISE for a SLOWER closing speed.

-Turn the speed adjusting valve COUNTER-CLOCKWISE for a FASTER closing speed.

2 "LATCH" speed adjustment is accomplished by full rotations of the speed adjusting valve.

-Turn the speed adjusting screw CLOCKWISE for a SLOWER closing speed.

-Turn the speed adjusting screw COUNTER-CLOCKWISE for a FASTER closing speed.

Top Jamb Installation

Closer Installs on Frame on

PUSH/STOP side of door.

Parallel Arm Installation

Closer installs on PUSH/STOP

side of door. * Optional

illustrated

Non Hold Open Arm

Left Hand Door-LH

Right Hand Reverse -RHR

See Page 2

illustrated

Non Hold Open Arm

Right Hand Door-RH

Left Hand Reverse -LHR

See Page 3

illustrated

Non Hold Open Arm

Right Hand Door-RH

Left Hand Reverse -LHR

See Page 4

Hinge Edge

of Door

Hinge Edge

of Door

CHART TO

DETERMINE HAND

OF DOOR

NOTE: These instructions apply only to closers equipped with backcheck action.

To increase backcheck intensity, turn "BC" valve clockwise.

To decrease backcheck intensity , turn"BC" Valve counter-clockwise.

OPENING CYCLE

INCREASE

DECREASE

Never close This

valve completely

BACKCHECK ADJUSTMENT

Backcheck

Range

CLOSING CYCLE

BC

A6-1/2

(165.1mm) 1-3/4(44.4mm)

1-1/4 (32 mm)

8-3/16(208mm)

3/4(19mm)

1(25.4mm)

Hinge

or

Pivot

OPENING

To120°

120°-180°

6-1/2(165.1mm)

DIM.A DIM.A

6 (152 mm)

4(101.6mm) 3-1/2 (89mm)

A6

(152mm) 1-3/4(44.4mm)

1-1/4 (32 mm)

9-1/16(230mm)

3/4(19mm)

1(25.4mm)

Hinge

or

Pivot

REGULAR ARM (PULL SIDE) Mounting

Size 4,5

Size 2 ,3

Size 2&3 Size 4&5

1. Select door opening angle and use dimensions shown above.

Mark four (4) holes on door leaf for closer body and two (2) holes on frame for arm shoe.

2. Drill pilot holes in door leaf and frame for #14 all-purpose screws for wood door/frame.

Or drill and tap for 1/4-20 machine screws for metal door/frame

3. Install forearm/arm shoe assembly to frame using provided screws.

4. Mount closer on door using provided screws. SPEED ADJUSTING VALVE MUST BE POSITIONED TOWARD

HINGE EDGE

5. Install main arm to top pinion shaft, perpendicular to door. Secure tightly with provided arm screw/washer assembly.

6. Adjust length of forearm so that forearm is perpendicular to frame when assembled to preloaded main arm (see below

iIlustration). Secure forearm to main arm with provided screw/washer assembly

7. Snap pinion cap over shaft at bottom of closer. If the slim cover is packed, please fix it by provided screws.

8. Adjust the door closer, following instructions as shown on page 1.

INSTALLATION SEQUENCE

Top View Typical Installation

SPEED

ADJUSTING

SCREW

SPEED

ADJUSTING

SCREW

"BC"

ADJUSTING SCREW

Preload Preload

Right hand door Left hand door

s

L

R

s

L

R

PAGE 2

Right hand door shown

Left hand door opposite

Dimensions are in inches(mm)

Do not scale drawing

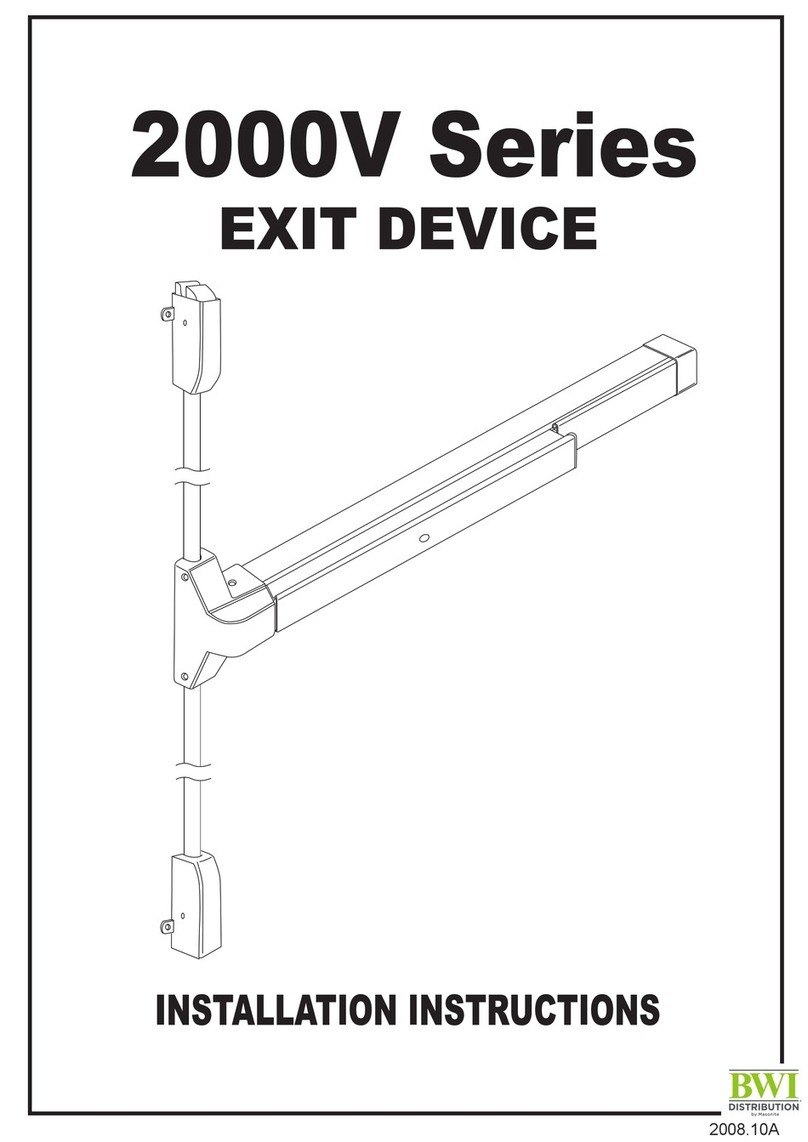

TOP JAMB (PUSH SIDE) Mounting

A8-3/16(208mm)

3/4(19mm)

1/2(12.7mm) 6-1/14

(158.7mm)

1-3/4(44.4mm)

1-3/4(44.4mm)

Hinge

or

Pivot

A9-1/16(230mm)

3/4(19mm)

1/2(12.7mm) 6

(152 mm) 1-3/4(44.4mm)

1-3/4(44.4mm)

Hinge

or

Pivot

OPENING

To120°

120°-180°

6-1/2(165.1mm)

DIM.A DIM.A

4(101.6mm)

6(152 mm)

3-1/2 (89mm)

Size 2&3 Size 4&5

1. Select door opening angle and use dimensions shown above.

Mark four (4) holes on door leaf for closer body and two (2) holes on frame for arm shoe.

2. Drill pilot holes in door leaf and frame for #14 all-purpose screws for wood door/frame.

Or drill and tap for 1/4-20 machine screws for metal door/frame

3. Install forearm/arm shoe assembly to frame using provided screws.

4. Mount closer on door using provided screws. SPEED ADJUSTING VALVE MUST BE POSITIONED TOWARD

HINGE EDGE

5. Install main arm to top pinion shaft, perpendicular to door. Secure tightly with provided arm screw/washer assembly.

6. Adjust length of forearm so that forearm is perpendicular to frame when assembled to preloaded main arm (see below

iIlustration). Secure forearm to main arm with provided screw/washer assembly

7. Snap pinion cap over shaft at bottom of closer. If the slim cover is packed, please fix it by provided screws.

8. Adjust the door closer, following instructions as shown on page 1.

INSTALLATION SEQUENCE

Top View Typical Installation

SPEED

ADJUSTING

SCREW

SPEED

ADJUSTING

SCREW

"BC"

ADJUSTING SCREW

Preload Preload

Right hand door Left hand door

s

L

R

s

L

R

Left hand door shown

Right hand door opposite

Dimensions are in inches(mm)

Do not scale drawing

PAGE 3

Size 4,5

Size 2 ,3

3/4(19mm)

A

B

9-1/16(230mm)

OPENING

To120°

120°-180°

DIM.A

10-3/4(273mm)

8-3/4(222.2mm)

DIM.B

7-13/16(198.4mm)

5-5/8(142.9mm)

DIM.A

7-3/4(197mm)

5-3/4(146mm)

DIM.B

6-1/8(156mm)

4-1/8(105mm)

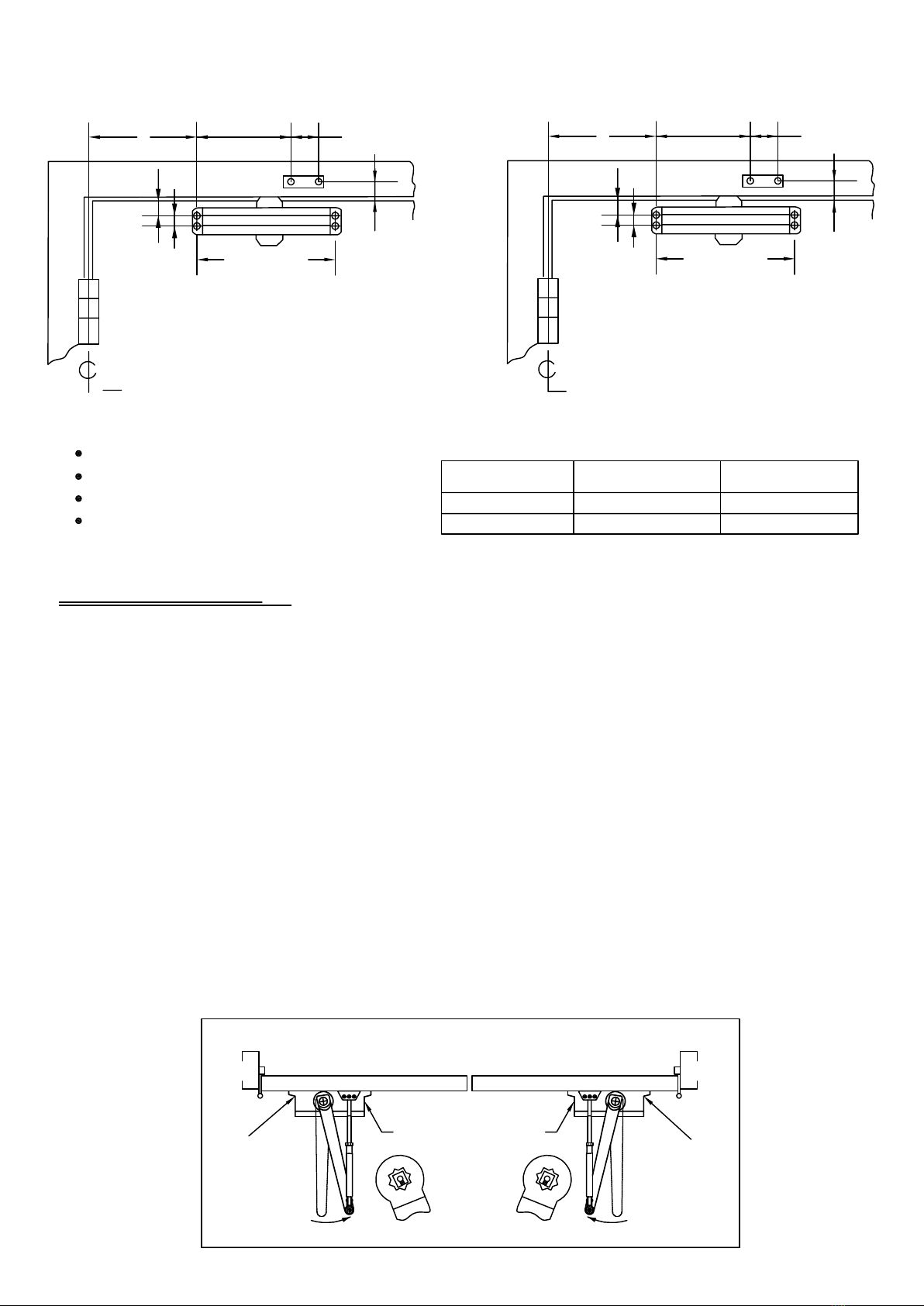

PARALLEL ARM (PUSH SIDE) Mounting

3 (76mm)

Size 2&3

5/16(8mm)

7/16(11mm)

3/8(9.5mm) 3/8(9.5mm)

2(50.8mm)

2-3/4(69.8mm)

3/4(19mm)

A

B

8-3/16(208mm)

3-3/8(85.7mm)

5/16(8mm)

7/16(11mm)

3/8(9.5mm) 3/8(9.5mm)

2(50.8mm)

2-3/4(69.8mm)

Size 4&5 Size 4&5

Size 4,5

Size 2,3

Size 2&3

1. Select door opening angle and use dimensions shown above .

Mark four (4) holes on door for door closer and four(4) holes underside of frame for paralle l bracket.

2. Drill pilot holes in door leaf and frame for #14 all-purpose screws for wood door/frame.

Or drill and tap for 1/4-20 machine screws for metal door/frame.

3. Mount closer on door using provided screws.

SPEED ADJUSTING VALVE MUST BE POSITIONED AWAY FROM HINGE EDGE

4. Install parallel Arm Bracket to frame using provided screws.

5. Using a wrench on the square shaft at bottom of closer, rotate shaft approximately 45 degrees toward hinge edge of door.

Hold and place main arm on top shaft of closer at proper index mark as illustrated .

FOR LEFT HAND DOOR "L"(illustration " A"). FOR RIGHT HAND DOOR "R"(illustration "B").

Tighten arm screw with Lock-washer securely.

6. Remove arm shoe f rom forearm and discard. Install rod end of forearm to bracket using provided screw/washer assembly.

7. Adjust length of adjustable forearm so that main arm is parallel to frame.

8. Adjust the door closer, following instuctions as shown on page 1.

INSTALLATION SEQUENCE

(A) (B)

Parallel arm Installation

Speed screws

Right hand door

Left hand door

S

R

L

S

L

R

45° 45°

Left hand door shown

Right hand door opposite

Dimensions are in inches (mm)

Do not scale drawing

Hinge

or

Pivot

PAGE 4

Popular Door Opening System manuals by other brands

Dormakaba

Dormakaba RTS88 installation instructions

Becker

Becker A100/25 5E Assembly and operating instructions

Automatic Technology

Automatic Technology TEMPO ATS-2 installation instructions

Dormakaba

Dormakaba RTS Series installation instructions

Dorma

Dorma AGILE 150 Installation instruction

Visionis

Visionis VIS-440 Series installation manual

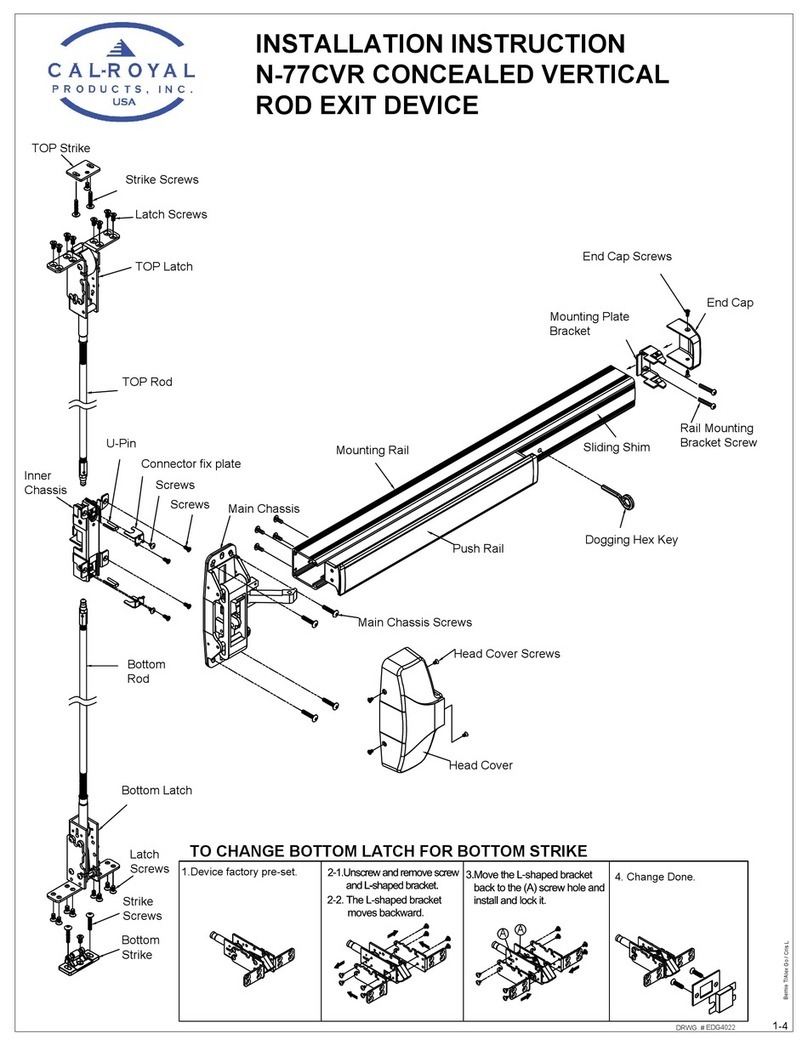

Cal-Royal

Cal-Royal N-77CVR installation instructions

Besam

Besam SW200i owner's manual

TOPP

TOPP M200 Instructions for installation and use

Raynor

Raynor ControlHoist CMT Installation instructions manual

Dictator

Dictator DICTAMAT 50 BK-Z Technical manual

Assa Abloy

Assa Abloy Adams Rite EX88 Preparation Guide and Installation Instructions