MM050_INTRO REV00-12.12.19

© Fort Vale Engineering Ltd. 2019

www.fortvale.com

Maintenance Manual - Introduction

2.7"NB Super Maxi Rail Relief Valve

To prevent damage to the valve:

·use the recommended tools to do the maintenance and to test the valve.

IMPORTANT

This maintenance manual contains instructions to do the maintenance and testing on the 2.7" Super Maxi rail relief valve,

part number series 0R3/XXXX006X.

·use the recommended tools.

WARNING :A relief valve is a spring-loaded device which can cause serious injury to personnel. Obey

all the maintenance and safety precautions.

·be careful during maintenance.

·use the applicable PPE.

Read all the information and instructions before you start the procedure. Keep this manual.

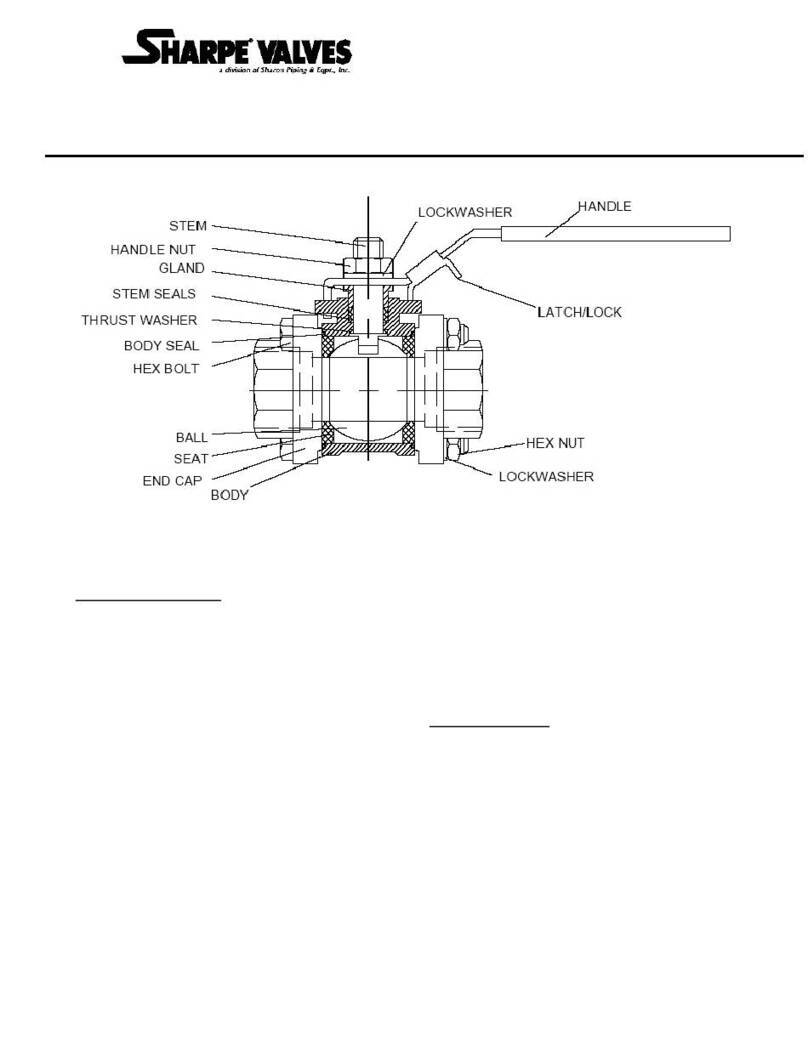

Overview

Maintenance Precautions

To prevent injury to personnel:

·obey all warnings.

The valve illustrated in this manual is part number 0R3/X165006R with a set pressure of 165 PSIG and a raised face

flange.

·injury to personnel.

·valve malfunction.

WARNING: If you install a replacement part that is not a genuine Fort Vale part, there is a risk of:

Identify your relief valve - the part number series will be marked on the valve cap. Please contact Fort Vale to order new

seal kits and replacement parts. Install only genuine spare parts.

·permanent damage to the valve or tank.

Replacement Parts

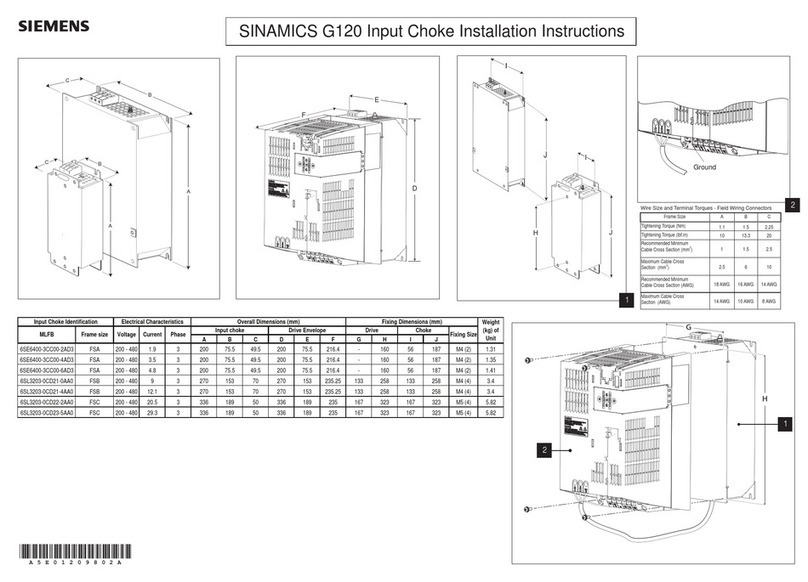

You will need general workshop equipment and hand tools and some special tools to do relief valve maintenance. Please

refer to Appendix A: Tools & Equipment.

·obey the recommended bolting sequence and Step Loading Procedure when you remove and install the valve

(see : Bolt Torque Guide & Step Loading Procedure).Appendix B

·use genuine Fort Vale spare parts.

·read Client Responsibilities ( ).see Appendix C

If you have a problem that you cannot solve using this manual, please contact us.

Tools & Equipment

®

MM050_REV033

Uncontrolledcopywhendownloadedorprinted.PleaserefertoFortValeforupdates.