Fort Vale Super Maxi 0R3/006 Series User manual

®

FORT VALE

Maintenance Manual

Super Maxi Relief Valve

AAR Specification

0R3/XXXX006X Series

MM050_REV01 03.05.18

This is an uncontrolled copy and will not be updated automatically.

Please refer to Fort Vale periodically for document revisions.

BEFORE ATTEMPTING DISASSEMBLY OR REMOVAL OF ANY FORT VALE

COMPONENT, ALWAYS DEPRESSURIZE AND DRAIN ANY PIPING SYSTEMS.

Prior to commencing any remedial work :

Prior to handling the valve, ascertain the last product carried and ensure that the valve has been correctly decontaminated.

Obtain a Material Safety Data Sheet for the last product carried and observe all the Health and Safety advice, particularly

with regards to P.P.E. (Personal Protection Equipment)

personnel

Servicing of valves should be conducted by a “Qualified Person”

The term “qualified person” relates to a person familiar with the installation, assembly, operation, applications and

limitations of the component. The person should have the qualifications corresponding to their responsibilities, such as

instruction and awareness to comply with all operational, regional and in-company regulations and requirements.

Limitations of use/Mis-use

Please observe the maximum allowable working pressure and the minimum/maximum allowable temperature range and

ensure that the valve is not operated outside these limitations. Use/operation outside these limits is at the risk of the user

and Fort Vale shall bear no responsibility for such actions.

Servicing

Fort Vale components are manufactured for longevity under normal and compatible working conditions. It is the

responsibility of the user to take into account the working conditions of the valve and to implement a regular service

schedule based upon individual circumstances. In addition, a thorough visual inspection of the valve should be made at

regular intervals to check for correct operation and signs of corrosion. It must be noted that working at extremes of

temperature and/or pressure will reduce the operational life of the valve between services.

AFTER ANY REMEDIAL WORK, ENSURE THAT THE VALVE IS LEAK TESTED PRIOR TO RETURNING TO SERVICE.

During service or testing, if any problem arises that cannot be resolved with the use of this Maintenance Manual, please

contact Fort Vale for further advice and assistance.

Risk assessment and hazard assessment

Fort Vale recommends a full and comprehensive risk and hazard assessment in accordance with national or local

legislation prior to servicing a valve. Not all service environments are the same and basic instructions may need to be

incorporated into the safe procedures for use of the end user. See examples below:

- Correct use of personal protection equipment when working with compressed gases

- Correct use of personal protection equipment when working with low temperature components

- Correct use of personal protection equipment when working with heavy components and the use of lifting equipment

- Training and competence of conducting pressure testing

Important Safety Notice

OPIN41 REV00-29.07.13

© Fort Vale Engineering Ltd. 2013

Page 1

Fort Vale Engineering Limited ·

·www.fortvale.com

Calder Vale Park, Simonstone Lane, Simonstone, Burnley, Lancashire BB12 7ND, U.K.

Tel : +44 (0)1282 687100 · Fax : +44 (0)1282 687110 · Email : [email protected]

Maintenance Safety Advice

®

Super Maxi Relief Valve - AAR Specification

CAUTION: The Super Maxi relief valve is a spring-loaded device. Exercise caution during maintenance and wear

the appropriate PPE.

Part number(s : 0R3/XXXX006X

Manual Contents

Tools Required

13mm/ ” A/F spanner & torque wrench

38mm/1 ” A/F spanner & torque wrench

Rocol® lubricant

Thread adhesive (eg. Loctite® 243)

Scribe

3/32” hex key

Hammer

Pillar drill - 4mm (No. 22) drill, 3/16”BSW tap

Bench press (1 tonne minimum)

Pressure test rig

Proprietary Tools Required - available from Fort Vale

Nylon lifting spacer - FIX/A/0035

Cap tightening tool - FIX/A/0034

Pressure adjustment tool - FIX/A/0015/23

Consumable Parts Required - available from Fort Vale

Pressure O ring - part number varies according to seal material. Please see data sheet USREL148 for details.

Always ensure that the seal material is compatible with the cargo and operating conditions.

Further components may be required, subject to wear and condition. Damaged, worn or corroded parts should

always be replaced with new parts. Please contact Fort Vale for part numbers and further advice if necessary.

Chapter 1 Complete Disassembly

Chapter 2 Complete Assembly

Chapter 3 Pressure Testing & Adjustment

Appendix USREL147 & USREL148 - Data Sheet

USREL185 - Part Number Breakdown

MM050_REV01© Fort Vale Engineering Ltd. 2018

THIS PAGE IS INTENTIONALLY BLANK

MM050_REV01© Fort Vale Engineering Ltd. 2018

Super Maxi Relief Valve - AAR Specification

Chapter 1

Super Maxi Relief Valve

Disassembly Procedure

This chapter covers complete disassembly of the valve.

N TE:

Depending upon the reason for service, every step may not be required.

Damaged, worn or corroded parts should be replaced with new.

All seals, gaskets and O rings should be replaced with new, unless

otherwise stated.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 1

Super Maxi Relief Valve - AAR Specification

Step 1. Identify the valve. The part number will be

laser marked on the cap. If in doubt, contact Fort

Vale.

Step 2. Note that the cap is retained by an anti-

tamper screw filled with lead shot.

Step 3. Use a 4mm No. 22) drill and drill out the

lead shot and grubscrew. This will unlock the cap

from the body.

Step 4. Clean the hole using compressed air.

Caution: Wear appropriate eye PPE.

Step 5. Use a scribe to detach the stainless steel

plug.

Step 6. Remove the stainless steel plug.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 2

Super Maxi Relief Valve - AAR Specification

Step 7. Select the nylon lifting spacer FIX/

A/0035) - dimensions as above.

Step 8. Locate the nylon lifting spacer FIX/

A/0035) onto a bench press. A minimum 1 tonne

press is required.

Step 9. Locate the valve onto the spacer. Ensure

that the body flange is located centrally.

Step 10. Select the cap tightening tool FIX/

A/0034). Locate the two pins on the tool into the

two blind holes on the cap.

Step 11. Ensure that the cap tightening tool is

located squarely on the cap.

Step 12. Apply pressure on the cap tightening

tool until the spring is compressed enough to allow

the valve body to rotate. Rotate the body

clockwise until it is disengaged from the cap.

WARNING: The valve is under spring load.

Exercise caution and wear the appropriate PPE.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 3

Super Maxi Relief Valve - AAR Specification

Step 13. Slowly retract the ram to allow the spring

to decompress. WARNING: The valve is under

spring load. Exercise caution and wear the

appropriate PPE.

Step 14. When the spring is completely

decompressed, retract the ram so that the valve

can be disassembled.

Step 15. Remove the cap tightening tool. Step 16. Remove the cap. Inspect the cap for

damage. If damaged, contact Fort Vale.

Step 17. Remove the springs. Inspect the springs

for damage or corrosion. If damaged, contact Fort

Vale.

Step 18. Remove the pressure plate assembly.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 4

Super Maxi Relief Valve - AAR Specification

Step 19. Remove the valve body. Inspect the

body for damage or corrosion. Pay particular

attention to the pressure plate sealing face and the

gasket sealing face. If damaged, contact Fort

Vale.

Step 20. Use a 13mm ½") spanner to loosen the

5/16" UNF nut on the pressure plate assembly.

Step 21. Remove the 5/16" UNF stud and nut. Step 22. Use a 13mm ½") spanner to remove the

5/16" nut from the stud. If the nut has seized, use

2x 5/16" nuts as shown to prevent damage to the

thread: Clamp nut 1 in a vice and tighten nut 2.

Unlock nut 3 by rotating it clockwise and counter-

clockwise. Remove nut 3.

Step 23. Use a wire brush to clean any adhesive

residue from the stud. Inspect the thread on the

stud. If it is damaged, replace the stud.

Step 24. To separate the inner and outer

pressure plate, insert a rod that is smaller in

diameter than the hole in the inner pressure plate.

Gently tap the rod with a hammer to disassemble

the inner pressure plate. Remove the retaining

washer.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 5

Super Maxi Relief Valve - AAR Specification

Step 25. Inspect inner pressure plate and the

washer for damage or corrosion. If damaged,

contact Fort Vale.

Step 26. Remove the O ring and discard. Inspect

the outer pressure plate for damage or corrosion.

If damaged, contact Fort Vale. Disassembly is now

complete.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 6

Super Maxi Relief Valve - AAR Specification

Chapter 2

Super Maxi Relief Valve

Assembly Procedure

This chapter covers complete assembly of the valve.

NO E:

Depending upon the reason for service, every step may not be required.

Damaged, worn or corroded parts should be replaced with new.

All seals, gaskets and O rings should be replaced with new, unless

otherwise stated.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 7

Super Maxi Relief Valve - AAR Specification

Step 27. Clean all pressure plate components

and inspect for damage or corrosion. If damaged,

contact Fort Vale.

1. 5/16"UNF nut; . Retaining washer;

3. 5/16"UNF x 30mm stud; 4. O ring;

5. Outer pressure plate; 6. Inner pressure plate.

Step 28. Apply thread adhesive to the thread of

the inner pressure plate.

Step 29. Locate the 5/16" UNF stud and tighten. Step 30 It is important to fully tighten the

assembly: Clamp the stud in a vice - take care not

to damage the thread. Tighten the pressure plate.

Remove the assembly from the vice.

Step 31. Locate a new O ring into the outer

pressure plate seal groove. Ensure that the O ring

is fully located around its circumference.

Step 32. Assemble the outer pressure plate onto

the inner pressure plate assembly.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 8

Super Maxi Relief Valve - AAR Specification

Step 33. Ensure that the O ring is uniformly

located.

Step 34. Locate the retaining washer.

Step 35. Apply thread adhesive to the thread of

the stud and locate the nut.

Step 36. Use a 13mm (½") torque wrench to

tighten the nut to a torque of 0 Nm (15 Lb.ft)

Step 37. Assembly of the pressure plate is

complete.

Step 38. Ensure that the valve body is clean and

free from damage or corrosion. Pay particular

attention to the sealing face. Locate the pressure

plate assembly into the body.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 9

Super Maxi Relief Valve - AAR Specification

Step 39. Ensure that the springs are clean and

free from damage or corrosion. Locate the springs.

Step 40. Apply Rocol® lubricant to the thread of

the cap. Lubrication will help to engage the body

and the cap.

Step 41. Locate the cap and ensure that the

springs are located in the grooves of the cap. To

complete the assembly process a bench press is

required (minimum 1 tonne). Following assembly,

a pressure test rig is required to set the valve

pressure.

Step 42. Locate the nylon lifting spacer (FIX/

A/0035) onto a bench press. Ensure that the ram

is retracted sufficiently to accommodate the valve

height.

Step 43. Locate the valve onto the spacer and

ensure that the body is positioned centrally.

Step 44. Select the cap tightening tool (FIX/

A/0034). Locate the two pins on the tool into the

two blind holes on the cap.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 10

Super Maxi Relief Valve - AAR Specification

Step 45. Ensure that the cap tightening tool is

located squarely on the cap.

Step 46. Slowly apply pressure to the ram to

compress the springs. WARNING: Exercise

caution and wear the appropriate PPE.

Step 47. Stop the ram when there is a gap of

approximately mm-3mm (1/8") between the cap

and the valve body. Lift the valve body and rotate

it counter-clockwise to engage the threads

between the body and the cap. Continue to screw

the body into the cap up to the last thread on the

valve body.

Step 48. When the cap is fully engaged, release

the pressure from the ram.

Step 49. Remove the cap tightening tool. The

assembly process is complete. The valve must be

pressure tested before it is put into service.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 11

THIS PAGE IS INTENTIONALLY BLANK

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 12

Super Maxi Relief Valve - AAR Specification

Chapter 3

Super Maxi Relief Valve

Pressure Test & Adjusting the Set Pressure

This chapter covers pressure testing and fine-adjustment of the pressure

setting of the valve.

N TE:

Depending upon the reason for service, every step may not be required.

Damaged, worn or corroded parts should be replaced with new.

All seals, gaskets and O rings should be replaced with new, unless

otherwise stated.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 13

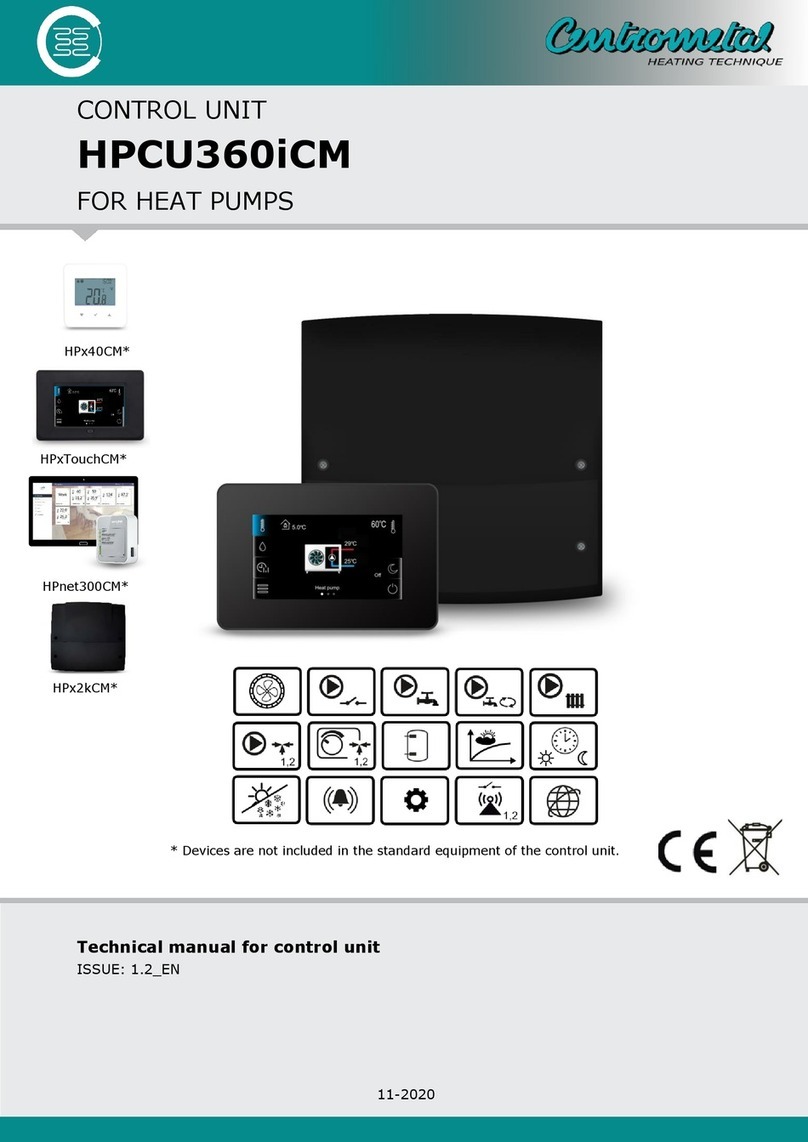

Super Maxi Relief Valve - AAR Specification

Step 50. Pressure testing should only be carried

out by a "qualified person". (See Maintenance

Safety Advice) A pressure test rig may be

purchased from Fort ale.

Step 51. Locate the valve body onto the 4x studs.

Step 52. Locate 4x washers. Step 53. Locate 4x nuts. Tighten the nuts in a

diametrically opposite sequence.

Step 54. Apply soapy water around the valve

where the pressure plate contacts the body.

Step 55. Apply pressure and look for bubbles

forming around the pressure plate. Note the

pressure at which this occurs. This indicates the

current set pressure of the valve. Exhaust the

pressure. To fine-adjust the valve to the required

set pressure, do the following:

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 14

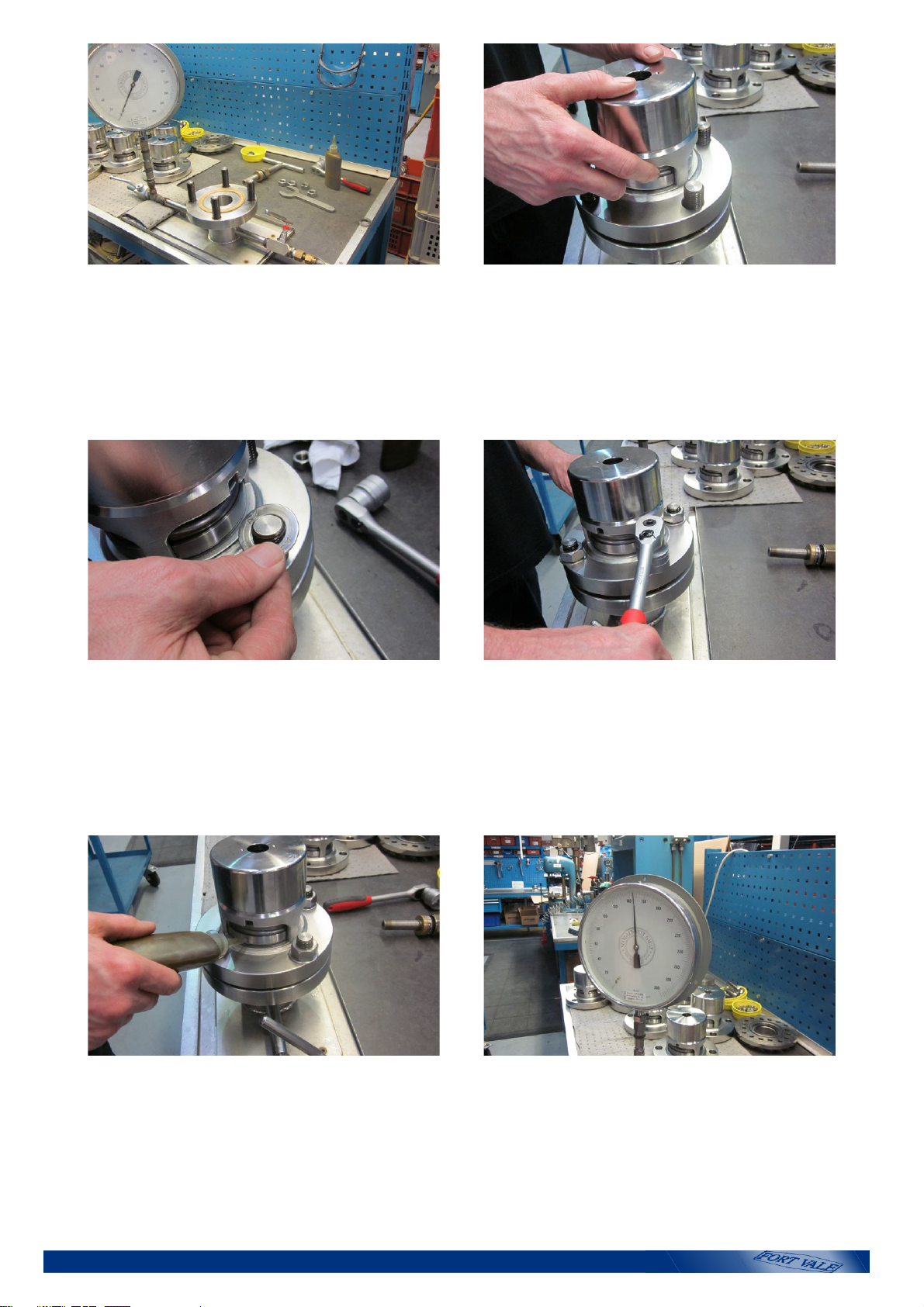

Super Maxi Relief Valve - AAR Specification

Step 56a. To adjust the pressure to the required

setting, use pressure adjustment tool FIX/

A/0015/23. The tool has a 5/16" UNF female

thread which is designed to engage onto the 5/16"

stud on the pressure plate.

Step 56b. Locate the tool through the hole in the

top cap. Engage the 5/16" female thread of the

tool with the 5/16" stud in the pressure plate and

screw it until it is fully engaged. WARNING:

Ensure that the pressure is exhausted and the

pressure supply is OFF before adjusting the valve.

Step 57. When the tool is fully engaged, hold the

tee bar and use a 38mm (1½") A/F spanner to

tighten the brass jacking nut. This action will lift the

pressure plate off the sealing face, allowing the

valve cap to rotate.

Step 58. PRESSURE TOO LOW: If the valve test

pressure result was lower than the target set

pressure, rotate the tool/cap assembly approx. ½

turn clockwise. Loosen the jacking nut to re-seat

the pressure plate. Unscrew and remove the

adjustment tool. Repeat the pressure test (Step 54

& Step 55).

Step 5 . PRESSURE TOO HIGH: If the valve test

pressure result was higher than the target set

pressure, rotate the tool/cap assembly approx. ½

turn counter-clockwise. Loosen the jacking nut to

re-seat the pressure plate. Unscrew and remove

the adjustment tool. Repeat the pressure test

(Step 54 & Step 55).

Step 60. If necessary, repeat the adjustment and

pressure test until the target set pressure is

achieved. When the set pressure is correct,

reduce the test rig pressure by 10%. Apply soapy

water and test at the reduced pressure. Ensure

that no bubbles appear. This confirms that the

valve has re-sealed.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 15

Super Maxi Relief Valve - AAR Specification

Step 61. When the valve is satisfactory, replace

the stainless steel plug. WARNING: Ensure that

the pressure is exhausted and the pressure supply

is OFF before removing the valve from the rig.

Step 62. When the pressure has been exhausted

from the test rig, remove the 4x nuts and washers

and remove the valve from the test rig.

Step 63. Refitting the anti-tamper screw: Use the

existing hole in the cap and drill a 4mm (No. 22)

hole to a depth of 5mm (0.2").

Step 64. Use a 3/16"BSW tap and tap the hole to

a depth of 4.6mm (0.18").

Step 65. Clean the hole using compressed air.

Caution: Wear appropriate eye PPE.

Step 66. Locate a 3/16"BSW x 3/16" long

sockethead screw. Use a 3/32" hex key to turn the

screw until it is recessed.

MM050_REV01© Fort Vale Engineering Ltd. 2018 Page 16

This manual suits for next models

4

Table of contents

Other Fort Vale Control Unit manuals