Forward DT150B User manual

Thank you for choosing Forward Vise. For future reference please record the following:

Inspection and Acceptance:

Claims for damage, shortage or errors in shipping must be reported within one (1) day

following delivery to Buyer.

Buyer shall have seven (7) days from the date Buyer receives any products to inspect

such products and services for defects and nonconformity which are not due to damage,

shortage or errors in shipping and notify Seller, in writing, of any defects, rejection or

nonconformity such products.

Specially fabricated or ordered items may not be canceled or returned, and no refund will

be made.

Product Specifications:

DT150B FORWARD MULTI-PURPOSE BENCH VISE 6IN

Jaw width:6" / Jaw Opening: 6" / Throat Depth: 3" / 360 Degree Rotating Head & Base

If there is any question about acondition being safe or unsafe, do not operate

the vise.

To avoid the risk of personal injury, equipment damage, fire & shock, make sure the work

area has the following conditions:

★The floor is dry. Damp, wet or rainy conditions can cause the operator to slip.

★The operator must be of sufficient age to operate vise in asafe condition.

★Well Lit.

★Clean and unobstructed.

★Workbench is properly secured to the floor or wall.

★Workbench is designed sufficiently to handle vise and workload (torque placed upon

the vise and workbench).

IMPORTANTS A F E T Y INSTRUCTIONS

Warnings: Misuse of vises c a n c a u s e seriousinjury toe y e s , hands a n d or other body parts.

V i s e s mustbe setup a n d used properly. B e f o r e setupa n d use, read, understand a n d

follow a l l instructions outlined below.

A L W A Y S makesurebench

tops a r e properly secured.

Never use a hammer, extension

pipe, or cheater bar on spindle

handle of vise.

A L W A Y S use proper nuts,

bolts a n d lockwashers ina l l

mounting holes, tohold bench

vise down.

NEVER unscrew movable jaw

beyond maximum specified

opening of vise.

A L W A Y S use vise of proper

sizea n d capacity tohold w o r k

object.

NEVER w e l d base of vise toa n y

metal object.

A L W A Y S wear e y e , face, a n d

ear protection w h e n striking or

using power tools with a vise.

NEVER use a vise topress a n

object into or out of another

object.

A L W A Y S wear dust maskor

respirator w h e n working with

wood, metal, chemical dusts

or mists.

NEVER use a n d extension pipe to

tighten handles of lockdowns.

A L W A Y S wear restrictive

hair covering a n d a n t i slip

footwear while operating vise.

NEVER place pressurized

containers or combustible

materials invise.

A L W A Y S hand tighten

handles of lockdowns f o r

swivelbase.

NEVER wear loose clothing or

jewelry while operating vise

A L W A Y S inspect vise f o r

stress fatigue or damage tothe

vise before using.

A L W A Y S maintain thevise –

g r e a s e main screw regularly.

NEVER apply extreme

heat or prolong heat tothevise a s

itmayalter structural properties.

MountV i s e ToAS e c u r e Workbench

1. Place vise on theworkbench toidentify thelocation of mounting holes.

2. F o r added strength totheworkbench prior toinstalling a n d securing vise, place a n 18”

x 18” x 2” piece of wood ( 1 8 ” x 18” x ¼” metal plate) totheunderneath side

3. Marka n d drill holes through theworkbench a n d wood/metal plate using theswivel

base a s thetemplate f o r themounting holes. Priortodrilling, makesurearea isfree &

clear of a n y hazards.

4. Install proper length &diameter bolts into theswivelbase of thevise.

Forward recommends a t theminimum thefollowing configuration: Install proper length

&diameter bolts along with f l a t washer through theswivelbase of thevise. The bolt

should be long enough toprotrude a t least 1” beyond, theunderside of theworkbench a n d

wood/metal plate. O n theunderside of theworkbench a n d wood/metal plate, place af l a t

washer, lockwasher a n d locking nut tothebolt. Securely tighten vise totheworkbench.

Periodically, recheck a n d re-tighten thenuts.

V i s e Operation

Makesurevise selection ( s i z e a n d type)isappropriate f o r use a n d application. Larger

vises a r e readily available through Forward V i s e s . Never force or use cheater bars, pipe

extensions on thescrew handle of thevise a s this places excessive pressure on thevise

components a n d theymayf a i l tor e s u l t insevere bodily injury.

Step1: Makesurevise issecurely mounted totheworkbench.

Step2: Makesuretheswivelbase lockdowns a r e secure.

Step3: O p e n thevise by turning thevise handle counterclockwise. D o not open beyond

thevises rated capacity ( j a w opening).

Step4: Place item between theserrated jawsof thevise.

Step5: Closethevise by turning thevise handle clockwise until theitem issnug between

theserrated jaws.

Step6: Continue totighten thescrew handle until y o u can no longer move (twist) the

clamped item. D o not over tighten a s this maydamage item and/or thevise.

Step7: Whenfinished working on theitem, slowly turnscrew handle counterclockwise

torelease theitem.

Swivel Base Operation

The vise is generally operated perpendicular to the workbench, enabling work to be

performed from either side of the vise. In some cases, the vise may need to be rotated to

allow better and safer access to the item.

In order to change the position of the vise, please follow the steps below:

Step 1: After the item is securely mounted in the vise, slowly loosen each lockdown

located on both sides of the vise. Care should be taken not to over-loosen or remove the

lockdowns as this may cause the vise to tip over and cause great bodily injury.

Loosen (turn counterclockwise) each lockdown about ¼ of a turn until the vise is able to

swivel from the base.

Step 2: Swivel the vise to allow better and safer access to the item.

Step 3: Tighten (turn clockwise) each lockdown so that the vise is securely clamped to

the base.

Full Version Of Terms And Conditions Of Sale

Available on-line at www.amazon.com/stores/node/8130830011 (select terms of sale).

Forward Tools

hongyuantools@outlook.com

AB

A

D

C

B

DT08125A

Replacement Parts Kits reafd

A. HANDLE & MAIN SCREW & NUT ASSY

B. JAW PLATES & “V” JAW & SCREWS ASSY

C. HEAD LOCKING HANDLE

D. SWIVEL BASE & LOCKING PAD & LOCKING NUT ASSY

aaa... AAA... HHHAAANNNDDDLLLEEE///SSSPPPIIINNNDDDLLLEEE AAASSSSSSYYY

PARTS DRAWING

REPLACEMENT PARTS ASSEMBLY:

Table of contents

Popular Tools manuals by other brands

Westfalia

Westfalia 72 93 76 instructions

General Pump

General Pump SMH Repair manual

SNOWJOE

SNOWJOE Aquajoe FIBERJACKET AJFJH50-58-RV-RM quick guide

Matco Tools

Matco Tools GG60A Operating instructions, warning information, parts breakdown

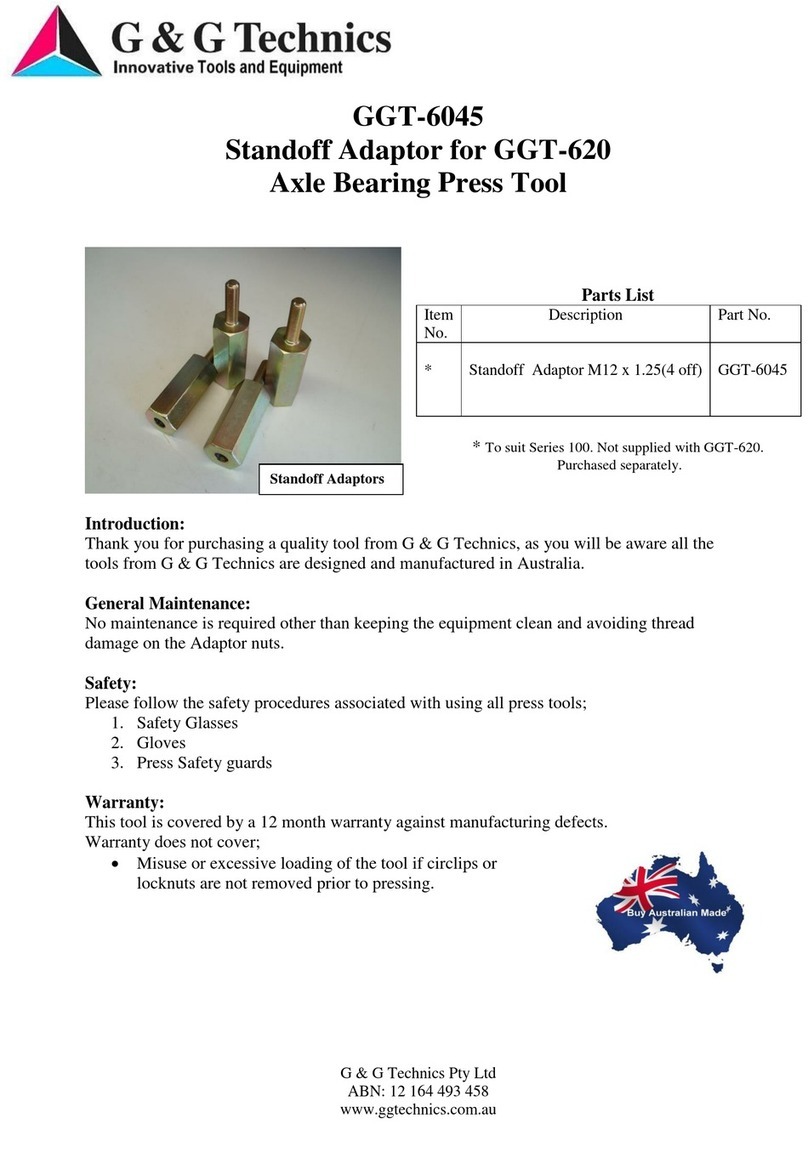

G&G Technics

G&G Technics GGT-6045 quick start guide

Fein

Fein FSC500QSL Repair instructions

Powerfix Profi

Powerfix Profi 283350 Operation and safety notes

DeWalt

DeWalt DXDP400161 instruction manual

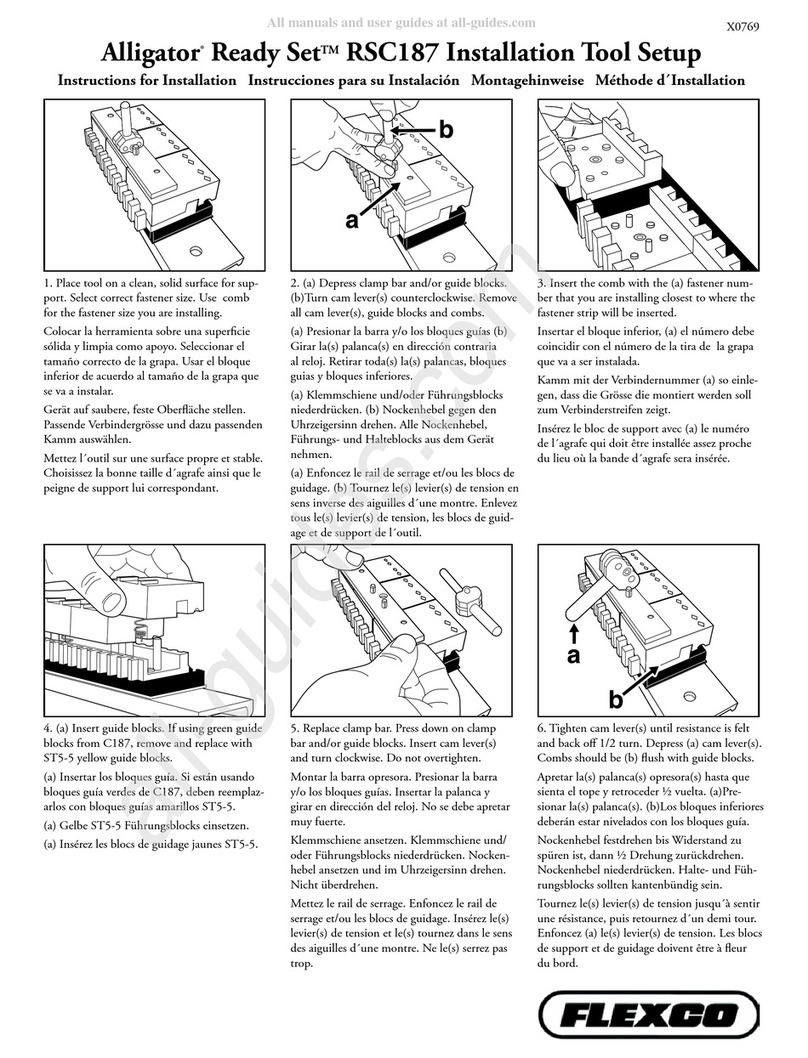

Flexco

Flexco Alligator Ready Set RSC187 Instructions for installation

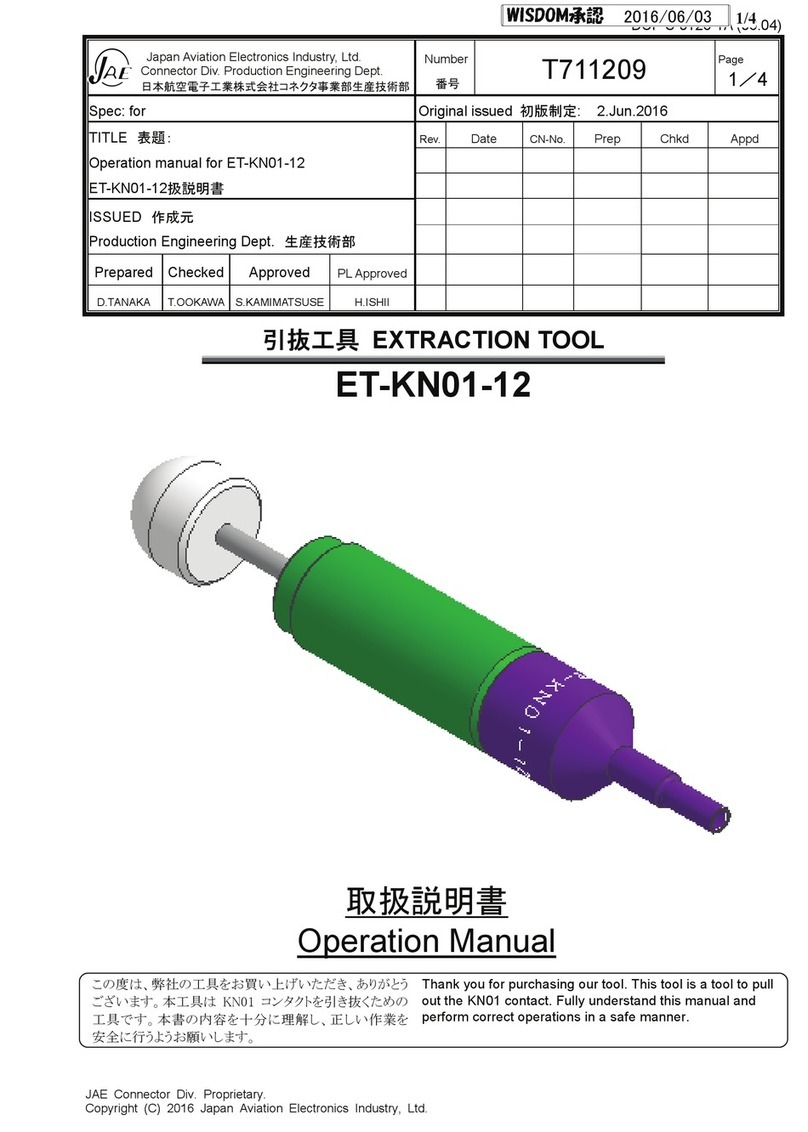

JAE

JAE ET-KN01-12 Operation manual

Hasler

Hasler HJOG 101 operating guide

Parkside

Parkside PDSP 1000 E6 Translation of the original instructions