1

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important information regarding the operation and warranty of the Forza Inverter Series. As with

any electrical equipment, certain precautions must be observed when installing the unit. To reduce the risk of personal

injury and to ensure safe installation and operation, carefully read and follow all instructions, cautions and warnings

included in this manual. Keep it in a safe place for future reference.

1. Before using the unit, read all instructions and cautionary markings on the unit, the batteries and all appropriate

sections of this manual.

2. CAUTION --Charge only deep-cycle lead acid rechargeable batteries. Other types of batteries may burst, causing

personal injury and damage.

3. Do not disassemble this product. If service or repair are required, consult a qualified service center.

4. Incorrect re-assembly may cause electric shock or fire.

5. To reduce the risk of electric shock, disconnect all wiring before attempting any maintenance or cleaning. Turning

off the unit will not reduce this risk.

6. CAUTION – Installation of the batteries should be performed only by qualified personnel.

7. NEVER charge a frozen battery.

8. For optimum performance of this inverter/charger, follow all wire and cable sizing specifications included in the

manual.

9. Avoid dropping tools onto batteries or other electrical parts.

10. Always use insulated tools.

11. This product must be connected to a permanent grounded wiring system.

12. All wiring and installation methods must comply with local codes and regulations.

13. Do not reverse the polarity of the battery cables. This will destroy the product.

14. Ensure that neither the AC nor the DC circuit is allowed to be short-circuited. Do not connect the system to any AC

source if a short circuit occurs.

1. Introduction

Thank you for purchasing the FUSION Off-grid solar inverter from Forza.

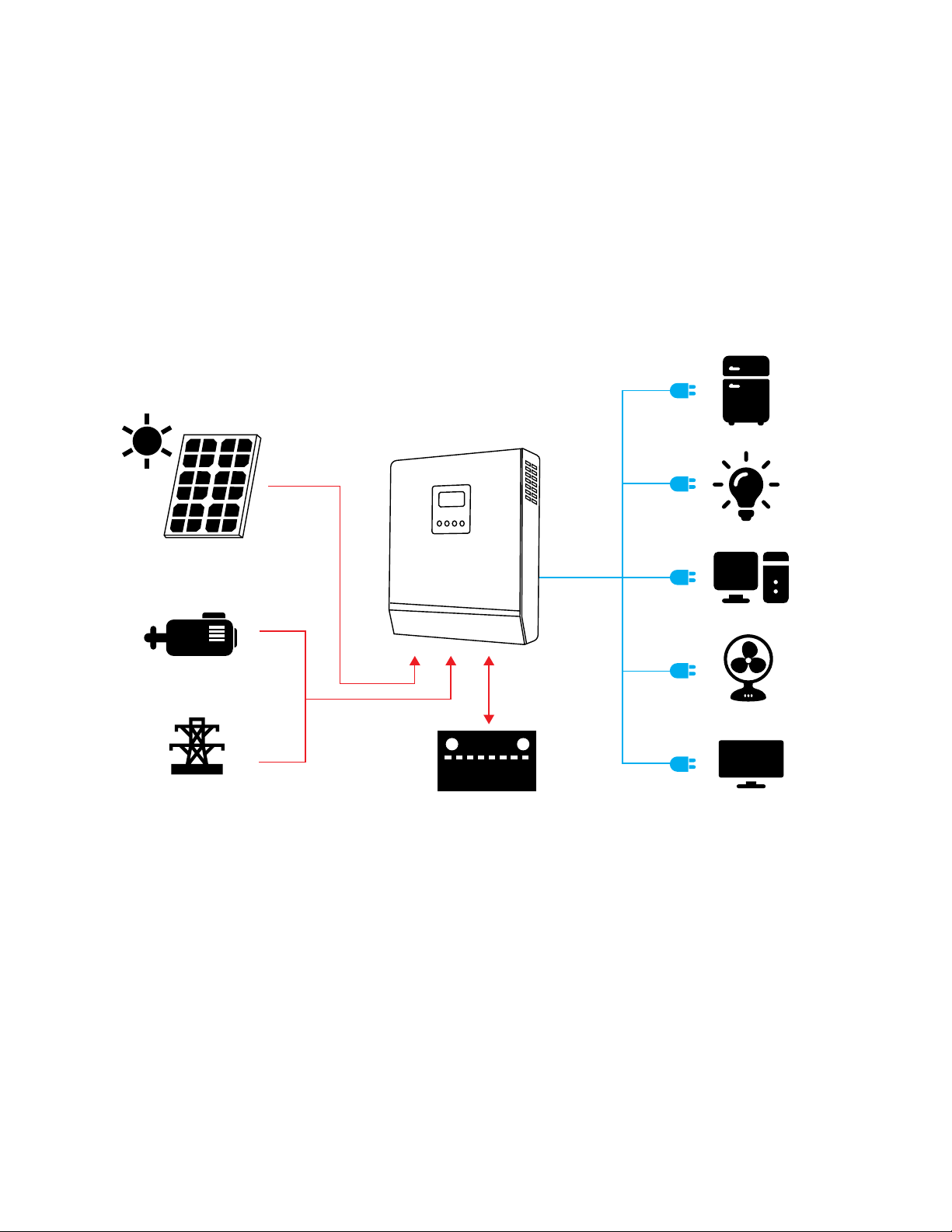

Our FUSION line is made up of inverters designed for off-grid, single-phase photovoltaic applications. Equipped with

an MPPT charger, the FUSION optimizes energy harvesting while reducing system maintenance and operational costs.

As the inverter has been conceived to easily integrate with the Forza battery and the embedded application, it provides

seamless status monitoring along with remote management, all in real-time. It also features parallel operation with up

to 9 identical units when used in conjunction with the optional parallel kit.

Available in the 120-volt version, and with capacities of 1000W, 2000W and 3000W respectively, the FUSION is

characterized for its sturdy construction, outstanding performance and industry-grade design life.

Features

• Zero (0ms) transfer time to protect mission-critical loads

• Pure sinewave solar inverter

• Highly efficient MPPT (Maximum Power Point Tracking) charge controller

• Output power factor of 1

• Features restart functionality, including the “cold start” option from battery

• Wide DC input range

• Selectable input voltage range for home appliances and personal computers

• Configurable AC/Solar input priority via LCD

• Marine/offshore and generator applications

• Smart battery charger design for optimized battery performance

• Rugged design with overload, overtemperature, and short-circuit protection

• Parallel operation with up to 9 units (requires parallel kit)

• Three-phase compatible in parallel operation (requires parallel kit)