FORZATEK X3 Series User manual

BATTERY CHARGERS - Series X3(3N) and X5 (5N)

Use and maintenance manual

anuel d'utilisation et d'entretien

rev. 10/18

1

Serie 3

N

/5

N

– Use and maintenance manual rev 10/18

1 WARNINGS - SAFETY ................................................................................................................................. 2

1.1 S

AFETY AND

R

EFERENCE

R

ULES

........................................................................................................................ 3

1.2 T

HERMAL SECURITY DEVICES AND SYSTEM

............................................................................................................ 3

1.3 E

LECTRICAL INFORMATION

.............................................................................................................................. 3

2 SERIES AND ODEL RANGES ..................................................................................................................... 4

2.1 S

ERIE

–

3N

AND

5N ..................................................................................................................................... 4

2.2 M

ODELS

-

A

DVANCED AND

P

ULSE

...................................................................................................................... 4

3 INSTALLATION AND POWERING ................................................................................................................ 4

3.1 C

HOOSING THE PLACE

................................................................................................................................... 4

3.2 C

HECKING THE

E

LECTRICAL SYSTEM LINE

............................................................................................................. 5

3.3 C

HECKING THE CHARGER AND THE BATTERY

.......................................................................................................... 5

3.4 C

ONNECTION OF THE BATTERY CHARGER TO THE

VA

C

M

AINS

..................................................................................... 5

3.5 V

AC ADJUSTMENT ON PO ER TRANSFORMER TAPPINGS

............................................................................................ 6

4 VISUALISATION......................................................................................................................................... 6

4.1 L

EDS

:

CHARGING STATUS

-

S

ERIE

3N

AND

5N ...................................................................................................... 7

4.2 S

INGLE PARAMETER OR GUIDE

.......................................................................................................................... 7

4.3 D

ISPLAY INFO

-

S

ERIE

5N

OR EXTERNAL KEYPAD

.................................................................................................. 8

5 OPERATION ................................................................................................................................................ 8

5.1 C

HARGER PO ERING AND BATTERY RECHARGE

....................................................................................................... 8

5.2 C

HARGING STOP AND BATTERY DISCONNECTION

..................................................................................................... 8

5.3 C

HARGING PROFILE A AND AP

-

FEATURES

....................................................................................................... 9

5.4 A

UTOMATIC TERMINATION OF THE CHARGE

-

DETAILS

.............................................................................................. 9

6 TROUBLE SHOOTING ................................................................................................................................ 10

7 AINTENANCE ......................................................................................................................................... 11

7.1 P

RELIMINARY RECOMMENDATIONS

................................................................................................................... 11

7.2 P

UT THE EQUIPMENT OUT OF SERVICE

............................................................................................................... 11

7.3 R

OUTINE MAINTENANCE

............................................................................................................................... 11

7.4 E

XTRAORDINARY MAINTENANCE

...................................................................................................................... 11

8 WARRANTY .............................................................................................................................................. 11

9 DRAWINGS AND TABLES .......................................................................................................................... 23

10 CURRENT TABLE, FUSES AND CABLES SECTION ...................................................................................... 31

2

1. WARNINGS - SAFETY

•Use the charger for charging a lead-acid battery only (PzS). It is not intended to supply power to an extra-low-

voltage electrical system or to charge dry-cell batteries. Charging dry-cell batteries may cause them to burst and

cause injury to persons and damage to property

•In order to reduce risks of explosion of the battery, please follow these instructions and those reported on the

battery:

•Never charge a frozen battery

•If it is necessary to remove battery from vehicle to charge it, always remove grounded terminal from battery

first. Make sure all accessories in the vehicle are off in order to prevent an arc and sparks

•Study all battery manufacturer’s specific precautions such as removing or not removing cell caps while charging

and recommended rates of charge

•Never place the charger directly above or below the battery being charged; gases or fluids from the battery will

corrode and damage the charger. locate the charger as far away from the battery as dc cables permit

•Connect and disconnect dc output clips only after setting any charger switches to the off position and removing

ac cord from the electric outlet. never allow clips to touch each other

•Follow these steps when battery is installed in vehicle. a spark near battery may cause a battery explosion. to

reduce risk of a spark near battery:

i) position ac and dc cords to reduce risk of damage by hood, door, or moving engine part.

ii) stay clear of fan blades, belts, pulleys, and other parts that can cause injury to persons.

iii) check polarity of battery posts. a positive (pos, p, +) battery post usually has a

larger diameter than a negative (neg, n, –) post.

iv) determine which post of battery is grounded (connected) to the chassis. if

negative post is grounded to chassis (as in most vehicles), see item (v). if positive post is grounded to the

chassis, see item (vi).

v) for a negative-grounded vehicle, connect the positive (red) clip from battery

charger to positive (pos, p, +) ungrounded post of battery. connect the negative

(black) clip to vehicle chassis or engine block away from battery. do not connect

clip to carburetor, fuel lines, or sheet-metal body parts. connect to a heavy gauge

metal part of the frame or engine block.

(vi) for a positive-grounded vehicle, connect the negative (black) clip from battery

charger to negative (neg, n, –) ungrounded post of battery. connect the positive

(red) clip to vehicle chassis or engine block away from battery. do not connect clip

to carburetor, fuel lines, or sheet-metal body parts. connect to a heavy gauge metal part of the frame or engine

block.

(vii) connect charger ac supply cord to electric outlet; and

(viii)when disconnecting charger, turn switches to off, disconnect ac cord, remove clip from vehicle chassis, and

then remove clip from battery terminal

•Follow these steps when battery is outside vehicle. a spark near the battery may cause a battery explosion. to

reduce risk of a spark near battery:

(i) check polarity of battery posts. a positive (pos, p, +) battery post usually has a

larger diameter than a negative (neg, n, –) post.

(ii) attach at least a 60 cm 6-gauge (awg) insulated battery cable to a negative

(neg, n, –) battery post.

(iii) connect the positive (red) charger clip to the positive (pos, p, +) post of battery.

(iv) position yourself and the free end of cable as far away from battery as possible, then connect the negative

(black) charger clip to free end of cable.

(v) do not face battery when making final connection.

(vi) connect charger ac supply cord to electrical outlet; and

(vii) when disconnecting charger, always do so in reverse sequence of connecting

procedure and break first connection while standing as far away from battery as

practical

•Use of an adapter is not allowed in Canada. if a grounding type receptacle is not available, do not use this

appliance until the proper outlet is installed by a qualified electrician

•For indoor use. provide adequate ventilation. do not expose to rain.

•Place the cabinet on a surface not flammable made of stone concrete or metal

•Before charging the battery read carefully the instruction

•Keep the documents in a clean and dry place for future consultations.

•Perform periodic routine maintenance and repairs.

•In case of failure: identify the reason, act accordingly and use only original spare parts.

•The battery charger is designed for an intermittent working, this means that it has to rest for the same amount

of hours it has worked

•orking in proximity of a lead acid battery is dangerous. batteries generate explosive gases during normal

operation. it is therefore of utmost importance that each time, before using the charger, you read and follow the

instructions provided.

•Explosive gases! avoid flames and sparks and provide proper ventilation of rooms.

•The battery charger is a device that can cause electric shock. it must be used only by personnel trained on

electrical hazards.

•Disconnect the supply before making or breaking the connection to the battery.

3

1.1 Safety and Reference Rules

The Battery Charger is made in accordance with the following rules:

CSA 22.2 No. 107.2 (2011) Battery Chargers and UL 1564 Industrial Battery Chargers

1.2 Thermal security devices and systems

Chargers are power supply devices. Their goal is to transfer energy from the electric grid to the battery. Therefore they

are devices that tend to create heat.

This must be considered as totally normal especially during the first hours of the charging cycle.

Charger is provided with two thermal protections. One to be considered in an absolute way the other one in a

preventive way.

1) The first thermal protection refers to one or more thermal probe on the power transformer able to stop the

charger cycle if the temperature reaches 150°C. Charger resume the cycle automatically just after the cooling

down of the power transformer.

2) The second type uses an algorithm in the electronic board able to predict the overheating of the power

transformer.

hen the system detects a possible overheating the charger turns off and on at intervals allowing partial cooling

of the transformer and thus avoiding the intervention of the thermal probes .

1.3 Electrical information

Read the electric data on the charger identification plate and check they are in conformity with your electric system

and the battery it should recharge:

1. Mains voltage. Input voltages that can be requested are: 600V-60Hz (Code 0) / 208-240-480V-60Hz (Code 1) for

three phase systems and 208-240V-60Hz (Code 2) and 120V-60Hz (code 4) for single-phase systems.

2. Electric grid Frequency set is 60Hz. Charger is not suitable for 50Hz grid frequency.

3. Battery voltage. Its voltage rating must correspond to the voltage of the battery charger

4. The maximum charging current. For the correct value, please refer the special capacity/current table, available

at our office. Such value is about the 14-16% of the nominal capacity C

5

of the battery considering the a

charging curve profile (11-13h), while is about the 20-22% for the Pulse profile (Ex: 600 Ah battery, initial

current using the a curve: 600x0,16=96 A, initial current using the ap charging curve in 7h: 600x0,22=132

A)

On the left we show the label of a typical charger

where are reported the above described parts.

For more details see the following sections

Model: Series 5NPS1 = 60Hz type Pulse (charge in 8h) Single phase 120V range with display

SERIAL NUMBER: Number for the unique

identification of BC followed by the model. The

latest numbers indicate the month and year of

production. In this specific example 315 means

March 2015

AC input: Show the voltage factory setting

(120V) Single phase (1ph) at 60 Hz.

5NPS1 model allows to adjust the AC with

following range options. (115-120-125-130V)

DC output: Shows the nominal voltage of the

battery and the output current at the rated

voltage

All other parameters mentioned refer to values

of maximum absorption, which is reached only

when the battery is fully discharged. Arrange

the electrical system so that it can deliver the power (2.275VA) and current (19A) reported on the label.

ARNING: The current and the power "constantly change" during the charging.

A 24V battery PzS varies its voltage during charge and can reach 32V. The current, on the contrary, continuously reduces

its value as the voltage rises. Any measurement of the values of power and current consumption during charging will be

different from the values stated on the label. Here below an example:

For example if during the charge you measure a battery voltage of 26.4V the output current must be close to 45A.

The output power will be around 1.870VA and the current absorbed 15,6A. This is normal.

Calculation refers to a nominal voltage of 120V-60Hz

If the charger electric data were not in accordance with your electric system or your battery, you must NOT connect them.

In case of malfunctions or failures, turn off the charger and do not try to arrange any repairing. Please call our technical

department or closest service center. Any reparation or replacement of parts must be authorised in writing by our

technical office.

The battery charger performs a decreasing current profile called a in conformity with DIN 41774 regulations. This profile

is determined by the technical characteristics of the power transformer. The power transformer is in fact provided with

different tappings in order to make sure the charging profile will result correct.

4

It is then essential to "adjust" the power transformer to the Vac values using related cables on tappings. Here is

procedure to follow:

Note: easure by a tester the real AC voltage during the charge and check it is the same as the

voltage set by the plug on the power transformer. Please match the voltage to the nearest value.

Please refer to section "INSTALLATION AND POWERING"

2. SERIES and ODEL RANGES

2.1 Series – 3N e 5N

These battery chargers are designed to work with 60Hz grid. They are available in two different series:

Series 3N – provided with simple LED interface. Suitable when you do not require to program the charger or to have

access to specific information. Note: PCB can be programmed in any case using an external keypad.

Series 5N – provided with LED interface, display and 4 keys. Charger display is provided with 4 digit (7 segments LED)

showing many information regarding the status of the charge: Voltage and battery current, Ah charged, duration of the

charge, type of anomaly and more. See all parameters at dedicated paragraph.

2.2 Models - dvanced and Pulse

Chargers are available in two models:

dvanced – refer to models performing a slow charge (typical. 10-13h). They are intended for daily overnight recharge

of a battery. They perform a cycle called a (DIN 41774).

Pulse – refer to models performing a fast charge (typical. 7-8h). They are intended for a double shift charge involving

one or more battery. They perform a cycle called ap.

Following table shows how to read the charger code

3 N A S 1

1 120V

2 208-240V

4 208-240-480V

6 600V

S

Single

-

phase

T

Three phase

A

Advanced

P

Pulse

N

60Hz

3

EDs

5

Display

3. INSTALLATION AND POWERING

Please, read carefully the chapter “Warnings and safety”

The installation must be made in accordance with the following instructions. The operation must be made in total absence

of power.

Terms of use:

-orking temperature and relative humidity: from 0° to 40°C (75%)

-Stocking temperature: from -20°C to 60°C

3.1 Choosing the place

•Put the Battery Charger in a suitable place, allowing an adequate air change, far from any heat source.

•Place the cabinet on a surface not inflammable as stone , concrete or metal.

•Chargers are heavy devices. They must be secured to prevent accidental falls. Place them on the ground or use

robust shelves .

•Make sure the Battery Charger command (OFF) have an easy access and that charging phase control panel (leds and

display) is well visible

5

3.2 Checking the electrical system line

•Make sure the electrical system line has been created in accordance with related current standards in force.

•The electrical connection must be made by qualified personnel.

e suggest to involve staff in a position to issue a " declaration of conformity " of the work performed .

The declaration must include the efficiency of the connection to the ground, the control of the electric plug rate and

of system to which it is connected.

•The electrical safety is guaranteed only when the power plug is correctly connected to an efficient ground system.

•Check that the electrical system can withstand the power of the battery charger ( VA ) and that the voltage and

frequency of the line comply ( Volts and Hz ) with the data of the charger.

•Make sure the charger is protected with appropriate time delay fuses. In case please refer to our tables

3.3 Checking the charger and the battery

•Check that the input Vac cables and the output battery ones are intact and perfectly insulated. Do the same with both

input and battery plugs.

ARNING : The installation or replacement of the charger plugs must be performed by qualified personnel .

•Ensure good ground insulation of the battery and the power cables .

•Make sure the " polarity " of the battery cables respects that of the battery charger.

•Check that the battery is suited to the charger in respect of both voltage (V) and capacity ( Ah )

•The battery must be ready to be charged , clean and with proper electrolyte level .

•The charger connected permanently have neither the power input cables nor the fuses. Install appropriate power

input cables and plugs and protect them with time delay fuses or circuit breaker . e recommend using

power outlets provided with switch.

3.4 Connection of the battery charger to the Vac Main

After ascertaining that all items are in conformity with the system you can proceed with the physical connection of the

charger to the AC Mains. In the final part of this manual you have available the drawings reporting this information .

1) The single-phase chargers in the P6C cabinet are provided with a plate on the front of the cabinet fixed with 4

screws 4,8x13 . Unscrewing them you have access a section where you can connect the charger to the AC Mains

and adapt the voltage. The cabinet is provided with a 20mm diameter hole expected to house a M20 or PG11

cable gland able to receive the input Ac mains cable and to lead it to the Ac Mains connection. The M20 cable

gland can get wires with diameters from 50to 13mm; PG11 from 5 to 10mm.

2) Single-phase and Three phase charger in the cabinet I2c are provided with a front door closed with a screw

4,8x13.

Unscrewing it, the door opens and you access three different sections:

a. The lower section where the connection with the AC Mains is provided.

b. The intermediate one where you can find the section dedicated to the adjustment of the Ac mains voltage

to the power transformer

c. The higher section where you can see the fuses and some other components.

The cabinet is provided with a plate screwed in the right part of the cabinet where the battery cables come out as well.

This plate has a hole of 25mm expected to house a M25 cable gland, PG 13.5 or PG 16 able to receive the input Ac mains

cable and to lead it to the Ac Mains connection. The M25 cable gland can receive cables with diameters from 8 to 17mm,

PG13.5 from 6 to 12mm and PG16 from 10 to 14mm.

The connection will take place in the following sequence :

1 ) Open the door ( I2C ) or plate ( P6C ) to access the section of Vac connection.

2 ) Pass the cable through the cable gland.

3 ) Strip the cables and provide terminals. The ground wire must have a ring terminal and be connected first to the

appropriate pin of mass .

4 ) Then connect the other power cables.

5 ) Place and block the input Vac cable by tightening the cable gland

6

3.5 Vac adjustment on power transformer tappings

•ARNING : the adjustment of the tapping on the power transformer with the corresponding Vac Mains is an

essential operation that cannot be underestimated.

•ARNING: To perform this operation you need to open the battery charger and check it energized.

The operation consists of reading, using a multimeter, the Vac voltage on the input terminals of the charger and

in choosing the correct terminal (or tapping) in conformity with Vac values measured.

Each BC has an internal label reporting the output used for each transformer terminal .

Here are the voltage ranges on related BC:

Models ___1 (i.e.: 5NPS1 - single-phase)

AC Mains from 110 to 112 from 113 to 117 from 118 to 122 from 123 to 127 from 128 to 132

Tapping 110V 115V 120V 125V 130V

Models ___2 (i.e.: 5NPS2 - singlephase)

AC Mains from 200 to 204 from 205 to 215 from 216 to 230 from 231 to 245 from 246 to 253

Tapping 200V 208V 224V 240V 250V

Models ___6 (i.e.: 5NPT6 - threephase)

AC Mains from 565 to 585 from 586 to 610

Tapping 575V 600V

•ARNING: The threephase Battery charger having code ____4 (i.e. 5NPT4) are multi-voltage: 208-240-480V

In this case you will have to pay attention also to the star-delta (DY) connection and to the voltage set on the

auxiliary transformer. Explanatory drawings are available at the end of this manual.

These chargers can adapt the voltage from 200V up to 260V and from 450V up to 510V

•The operation must be carried out by qualified personnel.

o Connect the power plug and switch on the charger. DO NOT connect the battery.

o Open the front door (I2C) or front plate (P6C) in order to access the adjusting voltage section.

o Measure the Vac input of the charger.

o Switch off the charger.

o Adjust the tapping of the power transformer to the nearest correct value measured following tables given.

Example: A battery charger 5NPS2 suitable for 240V is connected to an electricity grid. The reading of voltage

measured on the input terminals is 217V. Move the setting cable into terminal 224V.

• ARNING: After the adjusting operations we recommend to connect the battery and start the charge process.

Repeat the voltage measurement "during" the charge. If the mains voltage have an important fall (5V or more) you

have probably a section of the input cable which is too small or the same input cable is too long and far from the

primary energy source. Or you do not have the necessary input power.

Never use extension cords, especially rolled ones.

In case of doubts please double-check the connection to the network and all its elements.

If everything is under conformity values simply adapt the transformer terminal to the new voltage detected.

4. VISUALISATION

LED Colour Signal

L1 Green Battery ON The battery is present or the charge has started. Bulk phase

L2 Yellow Final charge Charger is in the final charge (V>2,4 V/cell)

L3 Green Battery Charged The battery is charged.

L4 Yellow ON The charger is in function and supplying current

L5 Red Alarm There is a fault or an anomaly

Switch Colour

ON/OFF Black Switch stop the Battery Charger

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

7

4.1 LEDs: charging status - Series 3N and 5N

Both 3N and 5N series are provided with 5 LEDs.

The leds can provide essential information on charging status of the battery and on possible alarms/error.

Legend: -- = LED off on = LED fixed light F = LED flashing

Visualisation of the charging phases

(For Alarms signals see section Troubleshooting)

Charger

Series

3N – 5N

Only

5N

L1 L2 L3 L4 L5

Display

Starting up -- on on on on on --

Company reference -- on on on on on Atib

Software release -- on on on on on r.5.2A(§)

Battery is not connected (typ <85%) -- F -- -- -- -- bAt

Leds conditions during the first 5 sec. after the start -- on -- -- -- -- Stop

Bulk phase (battery < 2,4 Vel) Phase 1

Supplying

current

on -- -- on -- P. --

Final charge . (Battery Voltage is > 2,4 V/el) Phase 2

Supplying

current

-- on -- on -- P. --

End of charge. Battery is ready to be used

--

-- -- on -- -- .End

Equalisation or Preservation phase. Phase 3 and 4

Supplying

current for 5

min

-- -- on on -- .Equ

LEDs also provide information about alarms .

To get all details please refer to the " Troubleshooting " table.

(*) The number after the letter P indicates the % of the battery charging status. See next paragraph

(§) or higher

4.2 Single Parameter or Guide

"Single Parameter" or "Guide" has been designed to provide a "single " data that shows, depending on specific situation,

the status of the BC or an intuitive alarm code.

This parameter is available on all SERIE 5N (being equipped with display) or by connecting the optional keypad on all

SERIE 3N models.

"Single Parameter" or "Guide" then provides information that "changes" during the charge.

In particular during the charging process it shows the code P followed by a number from 10 to 99

The value indicates the percentage of power that has been given to the battery , so P 50 indicates that the battery has

reached 50 % of the charge , P 80 the 80 % and so on . This parameter gives an indication of the status of the process, it

is not a measuring instrument.

Legend : -- = LED is off on = LED is ON fixed light F = LED is flashing

During the charge display LED display LED

P0-70

Charging Phase 1

1001 0 P80-99

Charging Phase 2

0101 0 Stop

BC is Idle

1000 0

bAt1

Vbat < Vnom

1001 0

Charge is completed

Endc

End

-

Ah

intervention

0001 0 Endd

End

–

Derivative

intervention

0001 0 Endt

End

–

Time

intervention

0001 0

Endu

End

–

Voltage

intervention

0001 0 Endn

End

-

Min Charge

intervention

0001 0

Alarm codes

bAt

Battery is missing

F000 0 ti e

Time > Tmax F1

1000 1 ter

Overtemperature

1000 F

bAt9

Vbat > Vmax

1000 1 E t2

Time F2 > 9h

1000 1 terc

Over temperature

by current control

1000 F

Tout

Overall time

1000 1

cUr

Ibat < Imin

1000 F

8

4.3 Display info - Series 5N or external keypad

Series 5N is provided with a 7 segment display high brightness

Same features refer to SERIE 3N if provided with external keypad

Along with the display our Series 5N is provided with 4 keys for scrolling diagnostic parameters and programming.

Here are each key function in standard ode.

Key << >> F

Function Equalisation Scroll backwards Scroll forward Confirm

Through the << and >> keys it is possible to scroll the following parameters:

n° Parameter Function Description

1 P--- Navigator It shows the charging condition of the battery (in %) or identifies the

alarms

2 A--- Battery Current It shows the charging current (Ampere)

3 U--- Battery Voltage It shows charge voltage (Volt)

4 C--- Total Capacity Accumulated capacity (Ah)

5 c--- Capacity: phase 1 Capacity accumulated during bulk phase (Ah)

6 T--- Overall Time Time elapsed since the beginning of the charge (h)

7 n--- N. of charges Number of performed charges

7 N --- Partial charges Showing the number of charges that lasted more than 30’

8 Eq- Equalisation Shows the equalisation cycle setting:

0 = never active 1 = always active 2 = every 5 cycles 3 = every 20

cycles

9 dEly Delay start - set Delayed start function (setting)

10 00.00 Delay start - clock Delayed start function (countdown)

11 ---- code_1 Vbat (12) Inom (34) (*)

12 ---- code_2 Code (1) CF (23) CFmin (4)

13 ---- code_3 AC (1) Alarm (2) Firmware (34)

(*) The last 3 codes are "setting identity codes", necessary in case of fault or PCB replacement.

Numbers reported between brackets represents the digit of the display : 1 = digit 1, 2 = digit 2 etc

(Eq) parameter referring to equalisation is a parameter that can be modified.

If for instance equalisation setting is Eq1=always active and you would like to set it to "never active" here is how you

have to proceed:

Go to parameter Equalisation pressing the key >> and up to "Eq 1"

Press M key ( display starts flashing )

Scroll backwards until display shows "Eq 0" (never active) then press F for confirmation.

The delayed start parameter ( dEly) is a modifiable one.

You can set a delayed start up to 24 hours with steps (step) of 15 min .

The procedure for setting is the same as described above for the equalization ( set)

If the clock ( clock ) shows 0:00 the delay is not set .

5. OPERATION

5.1 Charger powering and battery recharge

Charger performs the cycle automatically just after its connection to the battery and to AC Mains.

This is the procedure to follow:

Action Effect L1 L2 L3 L4 L5 Display

Connect the battery plug PCB lights on

1 0 0 0

0

Stop

Close AC switch PCB is preparing to operate

1 0 0

0 0

Stop

After about 5 seconds Charger supplies current

1 0 0 1 0

P --

Using the keys << and >> it is possible to see charging parameters (only on Series 5N or using the external keypad)

5.2 Charging stop and battery disconnection

ATTENTION: this procedure must be followed in order to avoid electric arcs:

Action Effect L1 L2 L3 L4 L5 Display

Press OFF button Charger stops supplying current

1 0 0 0 0

Stop

Disconnect the battery plug PCB turns off

0 0 0 0 0

--

9

NOTE : If the charge is completed (green LED L3 – on) and the charger is not working (yellow LED L4 – off) battery plug

can be disconnected avoiding electric arcs.

Connecting a new battery the charger re-starts automatically

5.3 Charging profile Wa and Wap - features

Chargers perform a decreasing current profile called a regulated by the rule DIN 41774

The cycle is divided in two parts:

The bulk phase : from beginning of the charge up to the gassing point (2,4Vel)

The final charger : from gassing point (2,4Vel) up to the end of the charge.

Once the cycle is completed the charger con perform additional equalisation and preservation charges.

Equalisation and preservation can be activated on demand.

Model indentified as Advanced performs a classical cycle having an estimated recharging time of about 10-13 hours. On

the other hand model identified as Pulse once completed the bulk phase (>2,4Vel) performs a different final phase.

Pulse cycle in fact at regular step defined by time (min) is able to force a current higher than on standard a profile in

order to accelerate the normal timing of final stage. The electronic board keep under control all charging parameters in

order to optimize the duration. Pulse profile is able to reduce time of recharger to 7-8h.

Here is a table that underline the functioning of both models:

Phase Charge Duration Advance / Pulse

1 Bulk

From beginning of charge up to Vbatt=2,4Vel

(programmable)

(min. 0,5 h – max 11 h)

Starts with (*) = 100% Inom

(@2,0Vel)

Ends = 50% Inom (@2,4Vel)

2 Final

From 2,4Vel up to the end of the charge. The arrest of

the cycle is defined by derivative (dV/dt) termination or

by capacitive (accumulation of Ah) termination.

Starts with = 50% Inom (@2,4Vel)

Ends (#) = 25% Inom (@2,65Vel)

3 Equalisation 5 min every hour for the following 15h

4 Preservation Once the Equalisation cycle is completed, 5 min every

15h until the charger is turned off.

(*) For details regarding Ah and related Inom please refer to dedicated Ah chart table

(#) Current values of Pulse model varies continuously during the final charge.

5.4 utomatic termination of the charge - details

The charger stops the charge when detects that the battery is fully charged.

It analyses and considers different parameters. Some are always in function, others can be activated or disabled on

demand.

Termination

by Factors determining charge termination

Time It is defined a max duration above which the charger stops the cycle. (disabling not permitted)

Voltage It is defined a max voltage above which the charger stops the cycle. (disabling not permitted)

Derivative

(dV/dt)

Termination is defined when voltage is no longer growing.

This type of termination is based on the assumption that when a battery is fully charged it cannot grow its

output voltage. PCB elaborates an algorithm able to determine the steepness (or derivate dV/dt) of the

curve referring to the battery voltage growth.

Values of this specific steepness is programmable (disabling permitted)

Charging

factor

Termination is defined when the charger has supplied all the Ah perviously descahrged adding a

percentage factor called "charging factor".

This termination is based on the assumption that it is necessary to reintegrate more Ah in respect of those

that have been previously taken out.

PCB elaborates an algorithm able to detect the Ah taken and at same time the Ah % set necesary to be

reintegrated.

If 200Ah are taken from the battery and charging factor has been set at 1,2 ( or 20%) the charger

concludes the cycle when 240Ah are accumulated (200Ah +20%)

Charging factor value is programmable (disabling permitted)

10

6. TROUBLE SHOOTING

Here is a list of information that starting from LEDs signals or coming from the "single parameter/Guide" offers some

typical faults.

ATTENTION: chargers can provide slightly different information depending on the fact they are single or three phase.

These depends on components presents in the electrical circuit

L1 L2

L3

L4

L5

Display

DESCRIPTION OF THE PROBLE

Information valid for single-phase systems (par. 4=2)

1 -- -- -- -- -- --

DC is missing: Battery is not connected to the charge or voltage is very low (7V).

Vac mains might be present.

The fuse protecting the diode bridge is burnt.

the battery plug is damaged , a battery cable is interrupted

Electronic board not powered or faulty.

2 F -- -- -- -- bAt DC under voltage: Battery is connected to the charger but voltage is below min

threshold (1,7Vel o 85% Vnom).

3 on -- -- -- F cur

AC ains is missing: Charger has attempted to start charging but detect that Vac

Mains is missing. Please check input plug connection, the main switch of the grid and

related input AC fuses. hen AC power is back the system restarts automatically

Information valid for three phase systems (par. 4=3)

4 -- -- -- -- -- --

AC and DC are missing: Both battery and input Vac Main are missing.

If Vac is present problem is connected to the auxiliary transformer or to its

connections.

The fuse protecting the diode bridge is burnt.

the battery plug is damaged , a battery cable is interrupted

The electronic card is not powered or is faulty

5 F -- -- -- -- bAt DC under voltage: Battery voltage is present, but the battery "is not" connected to

the charger or below min threshold (1,7Vel o 85% Vnom).

6 on -- -- -- -- Stop

AC ains is missing: Battery is present but Vac is missing. Please check input plug

connection, the main switch of the grid and related input AC fuses. Problem is

connected to the auxiliary transformer or to its connections.

Information valid for both single and three phase systems

7 on -- -- -- -- Stop Stop : Charger has been stopped through the push off button placed on the front

door.

8 on -- -- on

-- bAt1

ATTENTION: Charger is supplying current but nominal voltage has not yet reached

(between 85-100% Vnom). Battery capacity is probably too big (Ah).

After some minutes the charger might stop automatically for over-current alarm

9 on -- -- -- on

bAt9 Over Voltage: A rong Battery has been connected.

Battery has a higher voltage than expected (>120% Vnom)

10 on -- -- -- F cur

Under current: The current in the battery is below the minimum threshold (2-3 A).

Charger will try to restart every minutes on.

1) There might be a possible bad contact or a connection problem .

Check AC mains plug connection, the main switch of the electric line and the input

AC fuses

2) Battery is sulphated

3) The ammeter sensor or its connection cables are damaged.

11 on -- -- -- F tEr

tErc

Thermal fault: If the power transformer is hot one or more thermal probes are

open ( tEr ) or preventive intervention of the board to reduce the temperature of the

power transformer ( TERC ) .

hen the temperature drops probes are restored and the system restarts .

If the transformer is cold check the electrical circuit of the probe and of the stop

button (see the wiring diagrams ) . One or more probes on the transformer are not

working or possible damage of related wirings

12 on -- -- -- on

TiME

Ti E : Maximum charging time Phase 1has been exceeded: 11h (<2,4Vel)

t_t2 : Maximum charging time Phase 2 has been exceeded: 9h (>2,4Vel)

tout : Maximum global charging time has been exceeded: 18h (total)

Any of these alarms can be caused by following cases:

1) AC Mains is too low

2) Vac tapping on power transformer is not in the correct position

3) Battery is not suitable: too big or damaged. Battery does not reach 2,4Vel

4) rong card setting

ithout the AC Main , the display switches to standby mode ( -___ ) after one minute .

Pressing any key it turns on for another minute .

ATTENTION: during the starting up phase (see par 4.1) the charger has all the LEDs light ON for 10 sec

11

7. AINTENANCE

The maintenance schedule depends on use and operating conditions but, generally, it should not exceed three months.

The maintenance operations have to be made by specialised personnel, in compliance with safety rules.

At our offices, you can find the “Routine and extraordinary maintenance forms”.

WARNING : If you detect a problem and you can not take immediate action to solve it, please make sure the

charger is identified as not working and " NOT to be used " .

7.1 Preliminary recommendations

• Before performing maintenance or repairs make sure the power plug and the battery are both disconnected.

• Carefully clean all parts: the charger , the battery, the cables, all the plugs etc.

• If the power cord or battery cables show signs of wear and are also partially damaged, please have them replaced

immediately by qualified personnel .

• At our offices you can find available dedicated special " modules for routine and extraordinary maintenance"

7.2 Put the equipment out of service

hen you want to do a routine or extraordinary maintenance on your Battery Charger, or you do not want to use it for a

long time or there is a fault, you must keep it out of service.

Please follow these instructions:

•If the charger is in function switch it off.

•Rotate the AC mains switch in “off” position and disconnect the plug.

•Disconnect the battery plug.

Should you wish not to use your Battery Charger for a time, please do not expose it to heat or atmospheric agents, but

keep it in a dry, safe place. The AC main plug and the battery plug must be raised from the ground and secured.

7.3 Routine Maintenance

Perform maintenance every 3 months or any time it is necessary.

•Clean carefully the AC and battery cables. Check they are not damaged or burnt. In this case, replace them

immediately.

•Check the AC mains and battery plugs. If they are crushed or burnt or damaged, replace them immediately.

•Electrical equipment must not be exposed to dust and humidity. Clean the Battery Charger. Should it be too dirty or

damp, put it in a safer place. The same is valid for the battery.

7.4 Extraordinary Maintenance

Perform maintenance every year or when a problem occurs ( i.e. burning fuse ) or you notice a fault .

•Follow the checklist of “Routine maintenance”.

•Open the Battery Charger. Clean carefully the dust on each component: the printed circuits by a clean brush, on the

other components by a blow of compressed air; stay at 20 cm (8 inch) at least.

•Check the screws and electrical connections are well tightened. The use of a thermal imaging camera is an excellent

way to understand if there are loose connections or weak points where you must intervene . The charger should be

on for at least 10 minutes before you make measurements

•Check the fuses, the fuse holders and the moving mechanical parts (contactor).

•Request in advance replacement parts that are not available at your site.

12

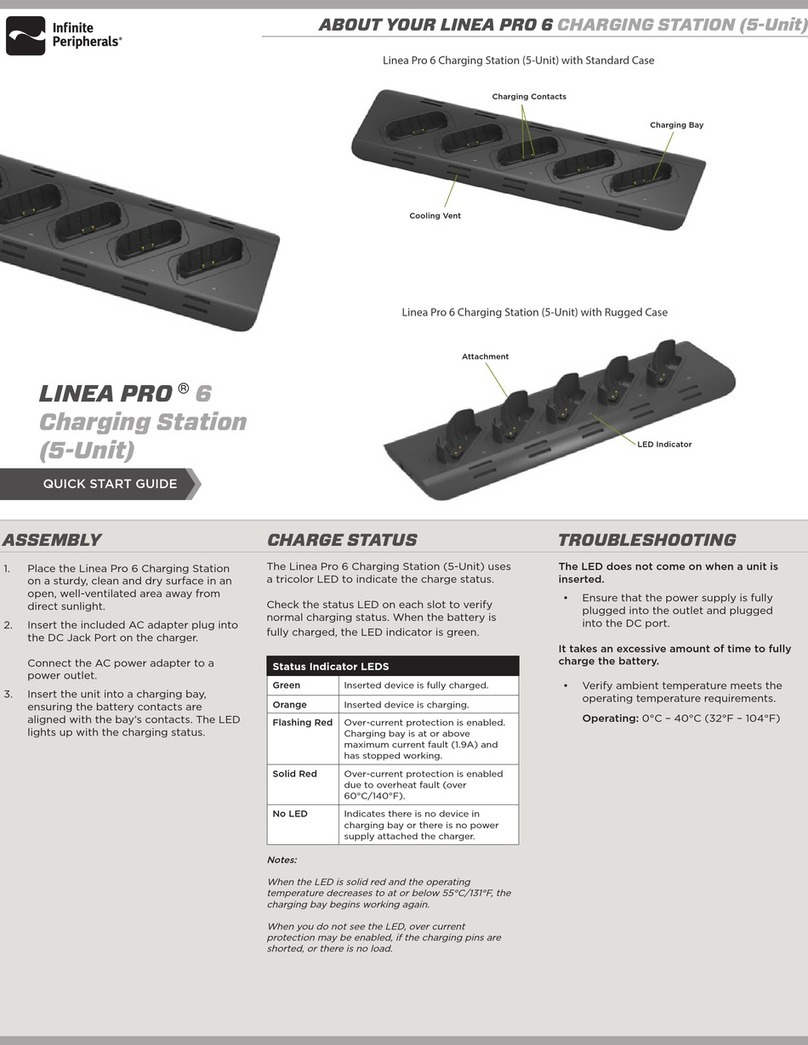

9. DRAWINGS and TABLES / SCHE AS TECHNIQUES et TABLEAUX

iring diagram and instructions to perform the installation and voltage adjustments / Schémas électriques et instructions

pour installer le chargeur et l’adapter au réseau

ADVANCED single-phase charger in the P6C cabinet / Chargeur type ADVANCED Monophasé dans le caisson P6c

13 mar 15

150_03_rev00

Advanced

Single phase charger

WH

OFF

t°

BK BN

7

8

RD

AT13

109

BROWN

BROWN

BN

BN

Faston

F1

FwdRew

M

VT

BK

BK

BROWN

BLACK

RED

VIOLET

BN

RD

BK

VT

TERMINAL AT12

1 2 3 4 5 6 7 8

BATTERY FUSE

DIODIES BRIDGE

BATTERY

+BGNDT°R-TA

11V-60Hz

41

6

FUSE

5x20 T500mA

FU3

5

TA

3 4

21109

+B

-B

FU1

(+)

(-)A.C.

A.C.

VD1

KA

GND

TRANSFORMER

POWER

TM1

BU

A2

A1

KM1

3

(E) 120V - 60Hz model 3NAS1 - 5NAS1

AC Main Single phase

(C) 240V - 60Hz model 3NAS2 - 5NAS2 (adaptableto 208V)

Permanently Connected

CARD

G2

AT13

CARD

G1

AT12

L3L2

T3T2

L1

T1

LN

LN

9

KM1

BN

(E)-(C) K

I J L

7

1

L

K

J

I

H(E)

110V

115V

120V

125V

130V

(C)

200V

208V

224V

240V

250V

BK

12Vdc

A1

A2

KA2

14

11

KA2

BN

BN

BU

GND

3 4 5 6

RD

FU5

5x20 F500mA

BN

Advanced

Serie 3N - no Display AT13 (G2)

Serie 5N - with Display AT13 (G2)

2

H

Cabinet P6c

1

7

110V

SETTING

-- - -7

115V

SETTING

-7 - --

120V

SETTING

7- - --

125V

SETTING

-- 7 --

-

110

115 (I)

6

N

L

2

3

4

5

130

7

125

-

115

- -

120

SETTING

130V

AC Main Cable

GND Secondary

GND AC Main M4x16

Neutro N

---

Fase L

110V (H)

120V (J)

125V (K)

130V (L)

120115 125 130110

120115 125 130110

120115 125 130110

120115 125 130110

Mains 128 - 132V

Mains 123 - 127V

Mains 118 - 122V

Mains 113 - 117V

Mains 110 - 112V

ADVANCED models

3NAS1 and 5NAS1 120V-60Hz

in Cabinet P6c

Keep the following information as guidelines. Read carefully the instructions for details

WARNING:

No Voltage into the charger when you move thewires.

Disconnect Mains and Battery plugs

1) First check the AC main Voltage on the Main Terminals and then switch off

2) Check or Move the wires 7 to the closer position (see table)

AC Main

Cable Battery

Cables

434

17 apr 15

155_01 rev00

ADVANCED 120V-60Hz in P6c Cabinet

Single phase chargers

13

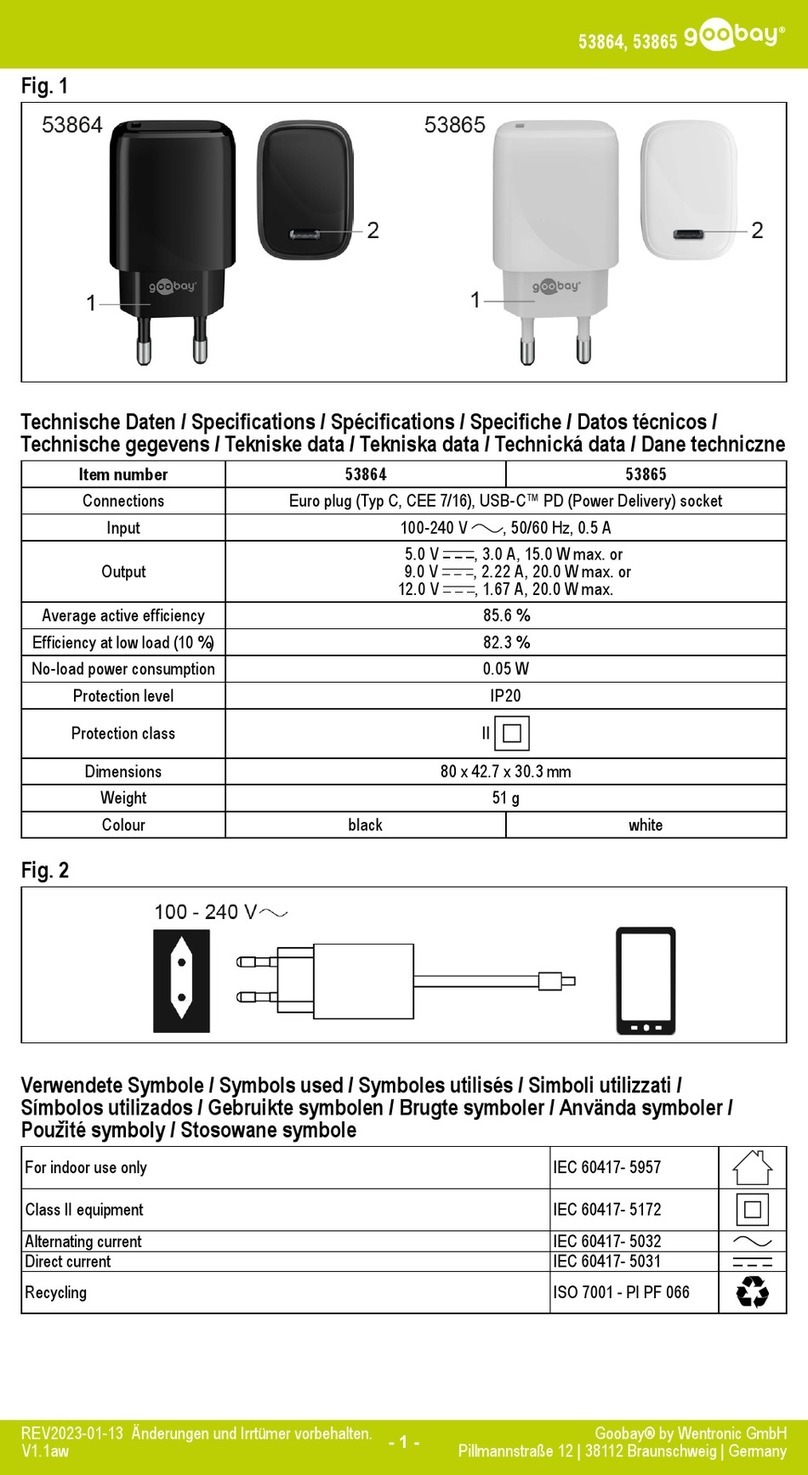

PULSE single phase charger in P6C cabinet / Chargeur type PULSE Monophasé dans le caisson P6c

13 mar 15

150_04_rev00

Pulse

Single phase charger

WH

OFF

t°

BK BN

BK

BK

BLACKBK

12Vdc

7

A1

A2

KA1

8

RD

AT13

109

BROWN

BROWN

BN

BN

Faston

F1

FwdRew

M

VT

BK

BK

BROWN

BLACK

RED

VIOLET

BN

RD

BK

VT

BLACKBK

TERMINAL AT12

1 2 3 4 5 6 7 8

BATTERY FUSE

DIODIES BRIDGE

BATTERY

+BGNDT°R-TA

11V-60Hz

41

6

FUSE

5x20 T500mA

FU3

5

TA

3 4

21109

+B

-B

FU1

(+)

(-)A.C.

A.C.

VD1

KA

GND

TRANSFORMER

POWER

TM1

22

21

22

21

WH

RD

BU

KM1

A1

A2

KM2

A2

A1

11

14 12

KA1 KM2

KM1

4

CARD

G2

AT13

CARD

G1

AT12

L3L2

T3T2

L1

T1

10

LN

LN

T3T1

L3L1

9

KM1 KM2

BN

(E)-(C) KI JLG

2

7

1

L

K

J

I

G(E)

Pulse

115V

120V

125V

130V

(C)

Pulse

208V

224V

240V

250V

RD WH

BK

12Vdc

A1

A2

KA2

14

11

KA2

BN

BN

BU

GND

3 4 5 6

8

11

12

RD

FU5

5x20 F500mA

L2

T2

BN

Pulse

Advanced

(E) 120V - 60Hz model 5NPS1

AC Main Single phase

(C) 240V - 60Hz model 5NPS2 (adaptable to 208V)

Permanently Connected

Cabinet P6c

Fase L

---

Neutro N

GND AC Main M4x16

GND Secondary

AC Main Cable

130V

SETTING

-- - 7

5

4

3

2

L

N

-7- -

SETTING

125V

--- 7

SETTING

120V

--7 -

SETTING

115V

7

2

120115 125 130

SETTING

SETTING

SETTING

130V (L)

125V (K)

120V (J)

115 (I)

130125115 120

130125115 120

130125115 120

Mains 113 - 117V

Mains 118 - 122V

Mains 123 - 127V

Mains 128 - 132V

PULSE models

5NPS1 120V-60Hz

in Cabinet P6c

Keep the following information as guidelines. Read carefully theinstructionsfor details

WARNING:

No Voltage into the charger when you move the wires.

Disconnect Mains and Battery plugs

1) First check the AC main Voltage on the Main Terminals and then switch off

2) Check or Move the wires 7 to the closer position(see table)

AC Main

Cable Battery

Cables

434

17 apr 15

155_02 rev00

PULSE 120V-60Hz in P6c Cabinet

Single phase chargers

14

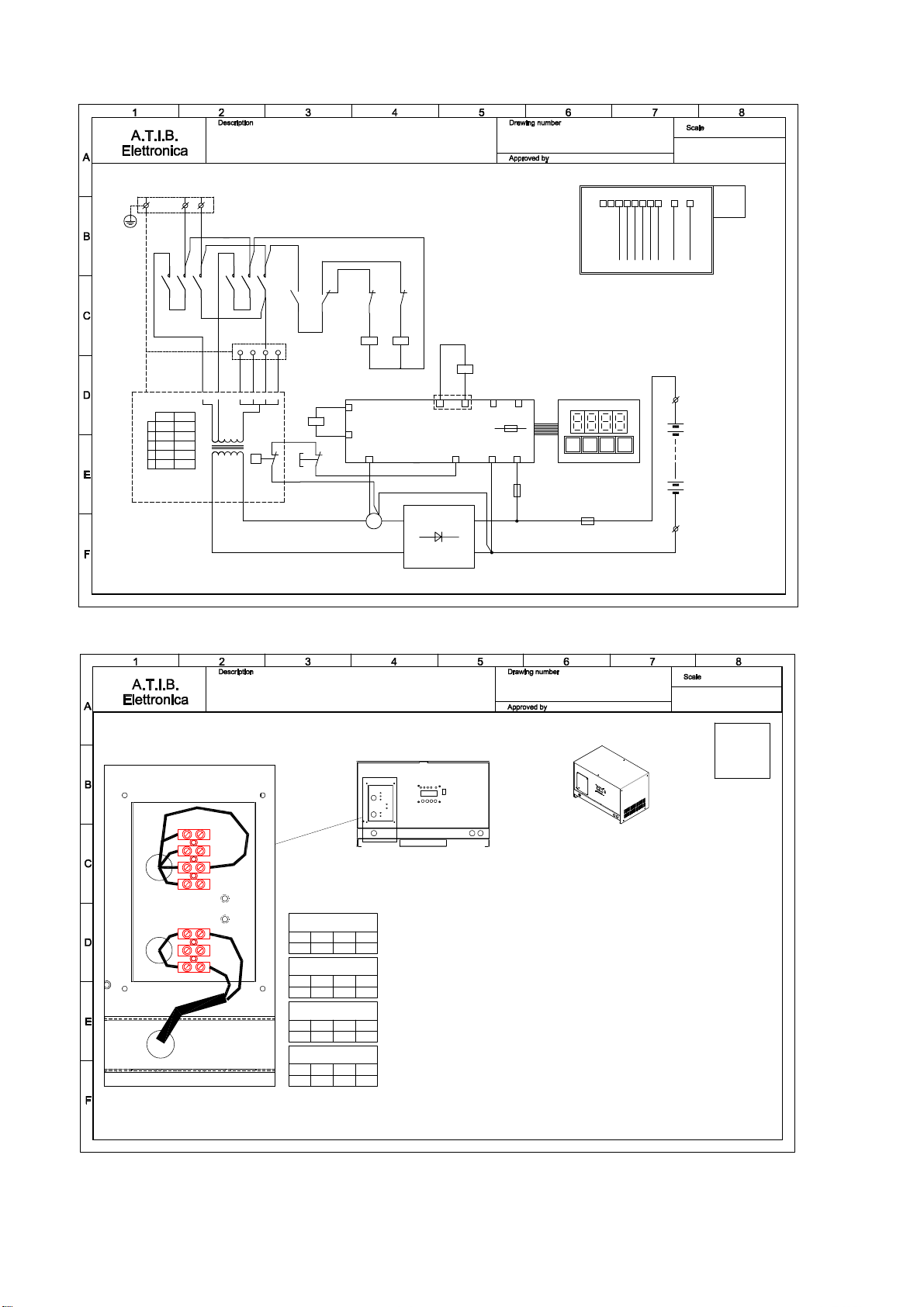

ADVANCED single phase charger in I2c cabinet / Chargeur type ADVANCED monophasé dans le caisson I2c

13 mar 15

150_11 rev.00

Advanced

Single phase charger

WH

OFF

t°

BK BN

7

8

RD

AT13

109

BROWN

BROWN

BN

BN

Faston

F1

FwdRew

M

VT

BK

BK

BROWN

BLACK

RED

VIOLET

BN

RD

BK

VT

TERMINAL AT12

12345678

BATTERY FUSE

DIODIES BRIDGE

BATTERY

+BGNDT°R-TA

11V-60Hz

41

6

FUSE

5x20 T500mA

FU3

5

TA

3 4

21109

+B

-B

FU1

(+)

(-)A.C.

A.C.

VD1

KA

GND

TRANSFORMER

POWER

TM1

11

CARD

G2

AT13

CARD

G1

AT12

L3L2

T3T2

L1

T1

LN

LN

9

KM1

BN

(E)-(C) KI JL

7

1

L

K

J

I

H(E)

110V

115V

120V

125V

130V

(C)

200V

208V

224V

240V

250V

BK

12Vdc

A1

A2

KA2

BN

BN

BU

GND

RD

FU5

5x20 F500mA

Advanced

BU

A2

A1

KM1

14

11

KA2

BN

H

(E) 120V - 60Hz model 3NAS1 - 5NAS1

AC Main Single phase

(C) 240V - 60Hz model 3NAS2 - 5NAS2 (adaptable to 208V)

Permanently Connected Cabinet I2c

Serie 3N - no Display AT13 (G2)

Serie 5N - with Display AT13 (G2)

H I J K L

L N

GND

MAIN

Secondary

GND

250240224208200

C

1 7

AC main Plate

Power Transformer Plate

-

SETTING

240V

-7- -1

C

C

1224

--

208 -

240 7

250

250V

SETTING

200

-

-

SETTING

224V

--- 71

C

C

1 -7 - -

208V

SETTING

-

7

SETTING

200V

--- -1

C

Components Plate

AC Main

Cable

200 250240208 224

200 250240208 224

200 250240208 224

200 250240208 224

ADVANCED models

3NAS2 and 5NAS2 240V-60Hz in Cabinet I2c

Mains 246 - 253V

Mains 231 - 245V

Mains 216 - 230V

Mains 205 - 215V

Mains 200 - 204V

7

435 4 38 PL10

terminal can change in according with power transformer

115120125130

C H I J K L C H I

115

J

120

K

125

L

130

C H

115

I

120

J

125

Battery

Cables

125

K

130

L

Keep the following information asguidelines.

Read carefully the instructions for details

WARNING: No Voltage into the charger when you move the wires.

Disconnect Mains and Battery plugs

1) First check the AC main Voltage on the Main Terminals and then switch off

2) Check or Move the wires 7 to the closer position(see table)

Do NOT move wires 1

17 apr 15

155_07 rev00

ADVANCED 240V-60Hz in I2 Cabinet

Single phase chargers

15

PULSE single phase charger in I2C cabinet / Chargeur type PULSE Monophasé dans le caisson I2c

13 mar 15

150_12 rev.00

Pulse

Single phase charger

WH

OFF

t°

BK BN

BK

BK

BLACKBK

12Vdc

7

A1

A2

KA1

8

RD

AT13

109

BROWN

BROWN

BN

BN

Faston

F1

FwdRew

M

VT

BK

BK

BROWN

BLACK

RED

VIOLET

BN

RD

BK

VT

BLACKBK

TERMINAL AT12

1 2 3 4 5 6 7 8

BATTERY FUSE

DIODIES BRIDGE

BATTERY

+BGNDT°R-TA

11V-60Hz

41

6

FUSE

5x20 T500mA

FU3

5

TA

3 4

21109

+B

-B

FU1

(+)

(-)A.C.

A.C.

VD1

KA

GND

TRANSFORMER

POWER

TM1

22

21

21

22

WH

RD

BU

KM1

A2

A1

KM2

A1

A2

11

14 12

KA1 KM2

KM1

12

CARD

G2

AT13

CARD

G1

AT12

L3L2

T3T2

L1

T1

10

LN

LN

T3T1

L3L1

9

KM1 KM2

BN

(E)-(C) KI JLG

2

7

1

L

K

J

I

G(E)

Pulse

115V

120V

125V

130V

(C)

Pulse

208V

224V

240V

250V

RD WH

BK

12Vdc

A1

A2

KA2

14

11

KA2

BN

BN

BU

GND

8

11

12

RD

FU5

5x20 F500mA

Pulse

Advanced

BN

L2

T2

(E) 120V - 60Hz model 5NPS1

AC Main Single phase

(C) 240V - 60Hz model 5NPS2 (adaptable to 208V)

Permanently Connected Cabinet I2c

G

G

G

115120125130

Battery

Cables

AC Main

Cable

Components Plate

2

G

SETTING

250V

7-- -1

C

2

SETTING

240V

-7- -1

C

C

1 7- - -

224V

SETTING

2

2

SETTING

208V

--7 -1

C

Power Transformer Plate

AC main Plate

721

C G I J K L

GND

Secondary

MAIN

GND NL

250240208 224

224208 240 250

224208 240 250

224208 240 250

Mains 205 - 215V

Mains 216 - 230V

Mains 231 - 245V

Mains 246 - 253V

PULSE models

5NPS2 240V-60Hz in Cabinet I2c

8

L

130

K

125

J

120

I

115

GC

130

L

125

K

120

J

115

IGCLKJIGC

130125120115

435 4 38 PL10

terminal can change in according with power transformer

Keep the following information as guidelines.

Read carefully the instructions for details

WARNING: No Voltage into the charger when you move the wires.

Disconnect Mains and Battery plugs

1) First check the AC main Voltage on the Main Terminals and then switch off

2) Check or Move the wires 7 to the closer position(see table)

Do NOT move wires 1

17 apr 15

155_08 rev00

PULSE 240V-60Hz in I2 Cabinet

Single phase chargers

16

ADVANCED Three phase charger 208-240-480V in I2c cabinet / Chargeur type ADVANCED Triphasé 208-240-480V dans le caisson I2c

12 mar 15

150_23_rev00

Advanced

Three phase charger

WH

BN

BK

t°

OFF

1097 8

BN

BN

BROWN

BROWN

5421 3

RED

BN

RD

VT

BK

BU

BU BLUE

VIOLET

BLACK

GREY

BROWN

6

TERMINAL AT12

F1

Fwd

M

Rew

AT13

Faston

GND

KA

RD

BATTERY FUSE

GY

BATTERY

FUSE

RD

BK

BN

L3

BU

BN BN

GY

L1 L2

BK

VT

DIODIES BRIDGE

POWER

TRANSFORMER

GY

D-Delta

Y-Star

21 3

TM1

7

8

+BGNDT°R-TA

11V-50Hz

10A/250V

41

6

A1

A2

5x20 T500mA

FU3

5

TA

3 4

21109

+B

-B

FU1

(+)

(-)A.C.

A.C.

A.C.

VD1

T3T2T1

L3L2L1

KM1

2 31 97 8

V1 W1

U2 V2

U1

W2

L1 L2L3

J

7 - 8 - 9

K L

KM1

23

CARD

G2

AT13

CARD

G1

AT12

B

C

D

1 - 2 - 3 Y

D

220208200 250240230 500480460

KJ L KJ L KJ LCB D CB D CB D

BK

L3L1 L2

Advanced

GND

FU5

5x20 F500mA

(B) 480V - 60Hz model 3NAT4 - 5NAT4 (default)

AC Main Three phase

Charger can ber adaptable to ...

Permanently Connected

(C) 240V - 60Hz

(D) 208V - 60Hz

Cabinet I2c

Serie 3N - no Display AT13 (G2)

Serie 5N - with Display AT13 (G2)

TM2 40VA

AUXILIARY

TRANSFORMER

0V

0V11V24V

FU2

5x20 F2A

FU4

6,3x32 T500mA

WH VT BU

208V240V

480V

B

A

B

A

B

A

B

AB

A

B

A

B

A

-

C D

1-2-3

B

-

-

C D

1-2-3

B

-

-

B1-2-3

DC

-

1-2-3

CB

-

1-2-3

CB

-

-

B

D

D

DD

D

208V

AUX. CIRCUIT 200V

SETTING

-

L

-

KJ

7-8-9

7-8-9

K L

-

J

--

SETTING 208V

AUX. CIRCUIT

208V

208V

AUX. CIRCUIT 220V

SETTING

-

K L

7-8-9

480V

AUX. CIRCUIT 460V

Y

SETTING

1-2-3

B-

L

-

KJ

7-8-9

7-8-9

K L

-

J

-

B

1-2-3

SETTING

Y

480V

AUX. CIRCUIT

480V

480V

AUX. CIRCUIT 500V

Y

SETTING

1-2-3

B-

K L

7-8-9 7-8-9

LK

--

D

SETTING 250V

AUX. CIRCUIT

240V

240V

AUX. CIRCUIT 240V

SETTING

D

- -

J-

LK

7-8-9

7-8-9

J K

-L

--

DC

1-2-3

SETTING 230V

AUX. CIRCUIT

240V

D

39

28

LKJDB CLKJDB CCB D J K L

7

1

-

J

D

--

C

C

- -

D

C

- -

D J

-J

-

Components Plate

AB

AB

Keep the following information as guidelines. Read carefully the instructions for details

WARNING: No Voltage into the charger when you move the wires. Disconnect Mains and Battery plugs

1) First check the AC main Voltage on the Main Terminals and then switch off

2) Check or Move the "Auxiliary circuit" (A) to the right range (208V - 240V or 480V)

3) Check or Move the "Changer" (B) in the right position (208V and 240 DELTA while 480V STAR ).

4) Check or Move the wires 1-2-3 in the right position (B=480V C=240V D=208V).

5) Check or Move the wires 7-8-9 to the closer position in the selected range. (see table)

AC Main

Cable

Battery

Cables

Secondary

GND

GND

MAIN

STAR - Y

U1 V1 W1

V2U2W2 BA

208V

240V

480V

L1 L2 L3

ADVANCED models

3NAT4 and 5NAT4 480V-60Hz in Cabinet I2c

Mains 491 - 510V Mains 246 - 253V Mains 216 - 225V

Mains 205 - 215VMains 236 - 245VMains 471 - 490V

Mains 450 - 470V Mains 226 - 235V Mains 200 - 204V

9

LKJDCB

130125120115

435 4 34

terminal can change in according with power transformer

115120 125130

B C D J K L

17 apr 15

155_09 rev00

ADVANCED 208-240-480V-60Hz

Three phase chargers in I2 Cabinet

17

PULSE Three phase charger 208-240-480V in I2c cabinet /Chargeur type PULSE Triphasé 208-240-480V dans le caisson I2c

12 mar 15

150_24_rev00

Pulse

Three phase charger

WH

BN

BK

t° OFF

BK

208V

240V

1097 8

BN

BK

BK

BN

BLACK

BLACK

BROWN

BROWN

5421 3

RED

BN

RD

VT

BK

BU

BU BLUE

VIOLET

BLACK

GREY

BROWN

6

TERMINAL AT12

22

21

21

22

12Vdc

BK

F1

Fwd

M

Rew

AT13

Faston

GND

KA

A1

A2

KA1

RD

BATTERY FUSE

WH

RD

GY

BATTERY

FUSE

RD

BK

BN

BU

BN BN

GY

BK

VT

DIODIES BRIDGE

POWER

TRANSFORMER

GY

D-Delta

Y-Star

21 3

TM1

KM1

7

8

A1

A2

KM2

L1 L2 L3

T1 T2 T3

+BGNDT°R-TA

11V-50Hz

10A/250V

41

6

KM2

A1

A2

5x20 T500mA

FU3

5

TA

3 4

21109

+B

-B

FU1

(+)

(-)A.C.

A.C.

A.C.

VD1

0V

0V11V24V

480V

T3T2T1

L3L2L1

KM1

64 52 31 97 8

V1 W1

U2 V2

U1

W2

L1 L2L3

(H)-(J)

(4 - 5 - 6)-(7 - 8 - 9)

(I)-(K) (J)-(L)

KA1

21

24 22

KM2

KM1

24

CARD

G2

AT13

CARD

G1

AT12

B

C

D

1 - 2 - 3 Y

D

220208200 250240230 500480460

KJ L KJ L KJ LIH J IH J IH JCB D CB D CB D

RD WH

BK

L3L1 L2 L3L1 L2

Pulse Advanced

GND

FU5

5x20 F500mA

(B) 480V - 60Hz model 5NPT4 (default)

AC Main Three phase

Charger can ber adaptable to ...

Permanently Connected

(C) 240V - 60Hz

(D) 208V - 60Hz

Cabinet I2c

FU4

6,3x32 T500mA

WH VT BU

TM2 40VA

0V11V24V

FU2

5x20 F2A

AUXILIARY

TRANSFORMER

L3L2L1

480V

240V

208V

D

7-8-9

K L

-4-5-6

I J

--

D

SETTING 240V

AUX. CIRCUIT

240V

H

-

-

H

240V

AUX. CIRCUIT 250V

SETTING

D

- -

KJ

4-5-6 L

7-8-9

I

--

I7-8-9

L

4-5-6

J K

--

D

-

CB

1-2-3

SETTING

Y

500V

AUX. CIRCUIT

480V

H

-

-

H

480V

AUX. CIRCUIT 480V

Y

SETTING

1-2-3

B C

-D

- -

JI

4-5-6 -

LK

7-8-9

-

I7-8-9

L

4-5-6

J K

-

SETTING 220V

AUX. CIRCUIT

208V

H

-

-

H

208V

AUX. CIRCUIT 208V

SETTING

- -

JI

4-5-6 -

LK

7-8-9

D D

D

-

B C

1-2-3

-

B C

1-2-3

-

B1-2-3

DC

-

-

B1-2-3

DC

-

A B

AB

AB

ABABAB

9638521 4 7

CB D H I J K LCB D H I J K LLKJIHDB C

B

A

B

A

-

B1-2-3

DC

--

B

DD 208V

AUX. CIRCUIT 200V

SETTING

-

IH

4-5-6 -

L

-

KJ

7-8-9

480V

AUX. CIRCUIT 460V

Y

SETTING

1-2-3

B C

-D

- -

IH

4-5-6 -

L

-

KJ

7-8-9 7-8-9

J K

-L

-4-5-6

H I

--

DC

1-2-3

SETTING 230V

AUX. CIRCUIT

240V

Components Plate

AB

AB

C

Keep the following information as guidelines. Read carefully the instructions for details

WARNING: No Voltage into the charger when you move the wires. Disconnect Mains and Batteryplugs

1) First check the AC main Voltage on the Main Terminals and then switch off

2) Check or Move the "Auxiliary circuit" (A) to the right range (208V - 240V or 480V)

3) Check or Move the "Changer" (B) in the right position (208V and 240 DELTA while 480V STAR).

4) Check or Move the wires 1-2-3 in the right position (B=480V C=240V D=208V).

5) Check or Move the wires 4-5-6 and 7-8-9 to the closer position in the selected range. (see table)

AC Main

Cable

W2 U2 V2

W1V1U1

STAR - Y

MAIN

GND

GND

Secondary

PULSE models

5NPT4 480V-60Hz in Cabinet I2c

Mains 216 - 225VMains 246 - 253VMains 491 - 510V

Mains 471 - 490V

Mains 450 - 470V Mains 226 - 235V Mains 200 - 204V

Mains 205 - 215VMains 236 - 245V

10

435 4 34

terminal can change in according with power transformer

D H I J K L

Battery

Cables

LKJIHDCB B C

17 apr 15

155_10 rev00

PULSE 208-240-480V-60Hz

Three phase chargers in I2 Cabinet

18

ADVANCED Threphase charger 600V in I2c cabinet. / Chargeur type ADVANCED Triphasé 600V dans le caisson I2c

19

PULSE Threphase charger 600V in I2c cabinet. / Chargeur type PULSE Triphasé 600V dans le caisson I2c

This manual suits for next models

4

Table of contents