Foster Cherry Products Super Scrubber GG1700X User manual

1

GG1700X & GG2000X Manual

IMPORTANT INFORMATION

All Foster-Cherry Products Ltd products comply with the Health & Safety at Work Act 1974 and/or The Supply

of Machinery (Safety) Regulations 1992 and subsequent amendments.

CAREFULLY READ THIS MANUAL

It contains instructions and information regarding the preparation before use, safe operation and

maintenance of the machine. This instruction manual should be made available to all operators of this

machine.

Before attempting any work carefully check over the entire machine and lubricate as outlined in Section 5 -

GENERAL MAINTENANCE.

All information, illustrations and technical details given in this manual correspond to the latest design at this

time.

It is this company’s policy to continually develop its products and the right is reserved to alter designs and

specifications without prior notice.

When ordering spare parts please quote the machine serial number, model type and year of manufacture as

given on the manufacturer’s serial plate affixed to the machine.

Record this information below for future reference.

SERIAL NO …………………………. YEAR OF MANUFACTURE ………………………….

For Parts contact Adam Drewery Tel: 07901 338473 or email adam@fostersalescompany.co.uk

Any alteration or modification carried out on a Foster-Cherry Products product by any person other than

company personnel shall be the total responsibility of the said person.

ALWAYS USE GENUINE FOSTER-CHERRY PRODUCTS SPARE PARTS

2

CONTENTS

Section Page no.

1 Introduction 3

2 Safety Notes 4

A) Safety First 4

3 Attaching to the Tractor 5

4 Use of the Machine 6

5 General Maintenance 7

A) Daily 7

B) End of Season 7

3

INTRODUCTION

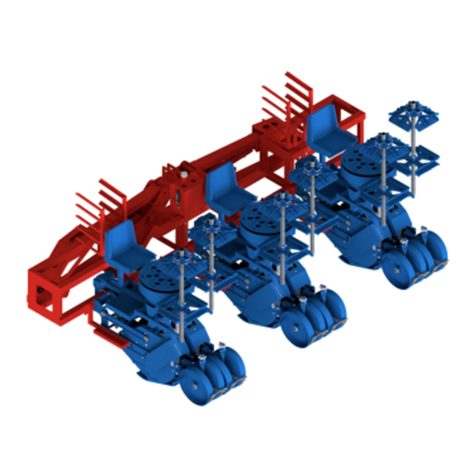

The Cherry-Foster GG Super Scrubber range is ideal for controlling Bracken, Rushes, Gorse

and Heather as well as creating woodland rides and forestry fire breaks. These machines can

handle heavy stone conditions.

GG1700X 66”cut 1.70m

GG2000X 78” cut 2.00m

The GG1700X is designed for use with tractors in the 60 to 100hp range, whilst the GG2000X

has a cuttingwidth of 6' 6" (2000mm), and is designed for usewith tractors in the100 to 130hp

range. Both models offer the option of a bolt on rear deflector assembly for use in heavy gorse

or light saplings in woodland to push over the material in readiness to be cut when used in

reverse.

The machine is constructed with heavy 6mm sides and top panel, substantially reinforced in

all vital areas with a pressed section superstructure to further improve strength and resistance

to stone damage, in addition to extensive box section reinforcement at the gearbox, skid and

tractor mountings. The machine also features a square rear profile to improve reverse cutting

performance, front and rear full width box section buffers fitted with heavy duty chain debris

guards to retain material for secondary cutting and tubular skids to minimise ground damage

when turning. The hinged headstock with twin suspension straps allow uneven ground

contours to be followed accurately.

Designed to be mounted in-line onto the rear 3 point linkage of a tractor, the machine is

powered by the tractor PTO, with the power transmitted through a direct drive gearbox to a

heavy duty rotor assembly with either three (1700) or four (2000) high tensile cutter chains or

blades attached. The direct drive system ensures that consistent performance in the most

arduous of conditions can be achieved without belt slippage or failure, and the system is

protected from overload with shearbolt and overun clutch protection. Please consult your

supplying dealer for details on further driveline protection including friction clutch /

gearbox options on the GG1700X.

Operating height is adjustable with the option of 3", 5" or 7" cutting heights for varying

applications. Unique tubular skids, reinforced at wearing points minimize ground or turf

damage when turning and skid height is adjusted by a simple pin system eliminating the use

of tools. All machines have in-line linkage to assist with stability when working in hilly or steep

land, and the A frame is free floating to allow the machine to follow the contours of the ground

in operation.

The high tensile chain cutters are used for all heavy conditions including woodland and scrub

growth to 1½" (38mm) diameter and are more practical than blades in stony conditions.

The high tensile blades cut grass and rushes cleanly, also bracken and heather in light stone

conditions, and require less tractor PTO horse-power than chains. Blade and Chain Cutters

can be interchanged in less than 15 minutes utilising the same rotor hub.

4

SAFETY NOTES

1. Never allow anyone to ride on the machine. Always keep other people away from the machine

when operating and always be aware of your surroundings/ bystanders may be deaf and/or

blind, therefore always exercise care.

2. Ensure the tractor has sufficient counter-balance weights fitted. If unsure, refer to the tractor

manual for reference.

3. Check all tyres for damage and inflation pressures.

4. Always be careful when exiting fields etc. on to public roads.

5. Check securing pins and lynch pins before using machine.

6. If any adjustments are to be carried out to the machine, always park on level ground, apply

the parking brake, stop the tractor engine, and remove the ignition key before dismounting

the tractor.

7. Check daily for loose nuts and bolts, on the cutter blade/cutter chain mounting on the rotor

assembly.

8. Always ensure that all the safety and chain debris guards are correctly fitted to the machine

before operation.

9. This machine is designed for use with tractors having a 540 rpm PTO speed with a standard 6

spline shaft. DO NOT exceed 540 rpm PTO speed.

10. Never engage the PTO or use the machine whilst in the RAISED position.

11. Never carry out any work under the raised machine without the correct safety supports in

place. NEVER RELY ONLY ON THE TRACTOR HYDRALUICS.

12. Operate only at a safe distance from bystanders and livestock and DO NOT operate along

highways or in any areas where people are present.

13. Use extra caution when operating on rough terrain and in areas where rocks and debris are

present. When used on sloping or steep ground always operate up and down the slope and

not across.

5

ATTACHING TO THE TRACTOR

•The GG1700X super scrubber is designed for use with tractors in the 80 to 120 HP range and

the PTO shaft is fitted with shear bolt protection and overrun clutch. The GG1700X has the

option of a friction clutch on the PTO shaft.

•The GG2000X super scrubber is deigned for the use with tractors in the 110 to 160 HP range

and the PTO shaft is fitted with a shear bolt and overrun clutch.

While it is necessary to manoeuvre the tractor to connect the machine to the 3-point linkage,

ensure that the tractor engine is switched off and the ignition key removed when fitting or

adjusting the PTO shaft.

A) Fit the Super Scrubber to the tractor 3-point linkage in the normal way, using the pins and

lynch pins provided. Always use the check chains/stay bars to limit the amount of sideways

movement. This will not only produce a better finish but will also help to prolong the life of

the machine

B) Ensure that when the machine is lifted, the top link mounting point is sufficiently clear of the

rear of the tractor cab/window. It may be necessary to limit the maximum height of the

tractor linkage.

C) Once the machine is attached to the 3-point linkage the PTO shaft should then be

connected. It may in some cases be necessary to shorten the PTO shaft to avoid the drive

shafts bottoming. If this is required, the following steps should be followed: -

i) Place the machine in its working position, flat down on level ground, apply the

parking brake, stop the tractor engine and remove the ignition key.

ii) Pull the PTO shaft apart and remove both shaft guards.

iii) Without re-assembling the shaft, fit the outer half to the machine end and the inner

half to the tractor, ensuring that both locking collars are engaged.

iv) Lay the two halved of the shaft side by side and check the overlap of the profile

tubes.

MINIMUM OVERLAP MUST NOT BE LESS THAN 350mm (14”) WITH A CLEARNCE OF

25-38mm (1” TO 1.5”) BETWEEN END OF TUBES AND YOKE WHEN THE DRIVE IS IN

ITS SHORTEST POSITON.

v) Should it be necessary to shorten the tubes, ensure that the ends are chamfered and

cleaned before re-assembly.

vi) On re-assembly the tubes should be well greased, and the guards fitted securely.

vii) On re-fitting the PTO shaft to the machine ensure that the PTO shaft securing chains

are attached on both halves of the guards to the tractor machine.

D) After fitting the PTO shaft, it will be necessary to lift the machine on the linkage to ensure

that the shaft does not foul on the front edge of the top panel of the machine. If contact can

be made, either the maximum lift height should be limited, or the top link, ensure that the

machine is still flat on the ground when lowered. If not, the maximum lift height must be

limited.

THE MANUFACTURER CANNOT BE HELD RESPONSIBLE FOR THE DAMAGE TO THE PTO

SHAFT CAUSED BY INCORRECT FITTING.

6

USE OF THE MACHINE

NB ANY ABUSE OF THE MACHINE WILL INVALIDATE THE WARRANTY AND COULD CREATE A SAFETY

HAZARD. USE ONLY AS RECOMMENDED IN THIS MANUAL.

A) Fit the machine to the tractor as instructed in section 2.

B) Lower the machine onto level ground; adjust the top link until the rear support straps are slack.

The machine, when operating, slide on the skids following the contours of the ground thus

maintaining an even cutting height and maximum effective guarding.

ONLY OPERATE MACHINE WITH THE SKIDS IN CONTACT WITH THE GROUND.

C) The required cutting height can be achieved by adjusting the side skids. There are 3 cutting

heights; 3”, 5” and 7”.

i) Raise the machine off the ground ensuring that it is fully supported. DO NOT RELY

ONLY ON THE TRACTOR HYDRALUICS.

ii) Before attempting any adjustment to the machine, always park on level ground, apply

the parking brake, stop the tractor engine and remove the ignition key before

dismounting the tractor.

iii) Remove skid adjuster pins, move skid to required cutting position and replace pins.

iv) Exercise caution when using blades in the lowest setting as the weight of the machine

may cause it to sink and possible grounding of the blade may result in scalping the

ground and potential blade damage.

D) Raise the machine to the transport position. DO NOT RAISE THE MACHINE OR TRAVEL TO THE

SITE TO BE CLEARED WITH THE PTO RUNNING.

E) Check the area to be worked is clear of potentially dangerous debris before commencing

cutting.

F) Check that all bystanders and livestock are well clear of the area to be cut. We recommend a

minimum of 100 metres.

G) Ensure all tractor doors and windows are closed.

H) Lower the machine to the ground. Engage PTO drive at a slow engine speed, increase engine

to give 540 rpm maximum. DO NOT ENGAGE PTO AT HIGH ENGINE REVS OR MECHANICAL

DAMAGE MAY BE CAUSED. DO NOT EXCEED 540 rpm.

I) Start cutting by moving forward at a safe working speed for the terrain and scrub to be cut.

Always start slowly to ensure that you become familiar with the operation of the machine.

Operation cutting speed is recommended as between 4 and 6 mph (subject to terrain).

J) The machine is designed to always operate with both side skids level on the ground.

K) Always reduce engine revs to tick-over before disengaging the PTO drive.

L) Always disengage the PTO before lifting the machine. DO NOT RUN THE MACHINE IN A RAISED

POSITION.

NEVER LEAVE THE TRACTOR SEAT WITH THE MACHINE RUNNING. ALWAYS PARK ON LEVEL

GROUND, APPLY THE PARKING BRAKE, STOP THE TRACTOR ENGINE AND REMOVE THE IGNITION

KEY BEFORE DISMOUTNING THE TRACTOR.

7

GENERAL MAINTENANCE

In order to ensure the extended durability and optimum performance of the machine, you are advised

to take careful note of the points laid out in this section.

APPLY THE PARKING BRAKE, STOP THE TRACTOR ENGINE AND REMOVE THE IGNITION KEY. NEVER

WORK UNDER A RAISED MACHINE WITHOUT THE USE OF PROPER SUPPORTS.

A) DAILY

i) CHECK gearbox oil level. The correct level is obtained by removing the plug mid way

up the back of the gearbox and filling until oil runs out of this hole. To fill with oil

remove the breather plug at the top of the gearbox. Use SAE 90 EP gear oil. Refit all

plugs. Ensure the breather plug is fitted to the top of the gearbox.

ii) Grease PTO shaft universal joints and sliding profiles.

iii) If cutter blades are fitted, they may require straightening, sharpening or replacing.

iv) Check cutter chains for damage/wear and replace where necessary.

v) Ensure that chain/blade locating bolts are tight and that the bushes are not worn.

WHEN REPLACING BUSHES OR CHAINS/BLADES, ALWAYS CHECK FOR WEAR AND DAMAGE TO THE

PIVOT BOLT AND NUT TO REPLACE IF NECESSARY. FAILURE TO DO THIS MAY RESULT IN

BLADES/CHAINS DETACHING THEMSELVES AND SERIOUS INJURY MAY RESULT.

vi) When the machine is new check tightness of all nuts and bolts after the first hour of

use and then on daily basis. Pay particular attention to the gearbox securing bolts and

the chain/blade mounting bolts.

vii) Ensure all safety guards and chain debris guards are correctly always fitted and swing

freely.

B) END OF SEASON

i) items ii to vii inclusive from daily maintenance.

ii) Empty oil from drive gearbox, clean with paraffin and fill with new SAE 90 EP oil. The

correct level is obtained by removing the plug mid-way up the back if the gearbox and

filling until oil runs out of hole. To fill with oil, remove the breather plug at the top of

the gearbox. Use SAE 90 EP oil. Refit all plugs. Ensure breather plug is fitted to top of

gearbox.

iii) Due to the corrosive nature of grass when cut, wash down the machine after use,

especially when the machine is being stored for a long period.

iv) Clear all debris wrapped around gearbox spindle and rotor disk.

v) Grease all areas where corrosion may occur.

vi) Check all chain debris guards and ensure they swing freely to produce a correct

guarding. Replace as necessary.

vii) Support the machine off the ground and store in clean, dry place.

viii) DO NOT USE A PRESSURE WASHER TO CLEAN THIS

MACHINE!

This manual suits for next models

1

Table of contents

Popular Farm Equipment manuals by other brands

OLIMAC

OLIMAC DRAGO Gold User and maintenance manual

LELY WELGER

LELY WELGER RPC 445 TORNADO operating manual

Hardi

Hardi MASTER VHY Series Instruction book

Bigham

Bigham Lilliston Rolling Cultivator Generation 3 Operator's manual

Ferrari

Ferrari FPA Operating and service manual

Original inside

Original inside TOP 620 A Operator's manual

JF

JF 30 EVO Operation & technical manual

Claydon

Claydon Hybrid Front Hopper Operator's manual and part's manual

AGT

AGT AGT-SSRPB80 product manual

enorossi

enorossi RR 420 EVO Use and maintenance manual

KUHN

KUHN GF 5000 T Assembly and operators manual

Belle Group

Belle Group Altrad Easy Screed Pro Operator's manual