7

SAFETY

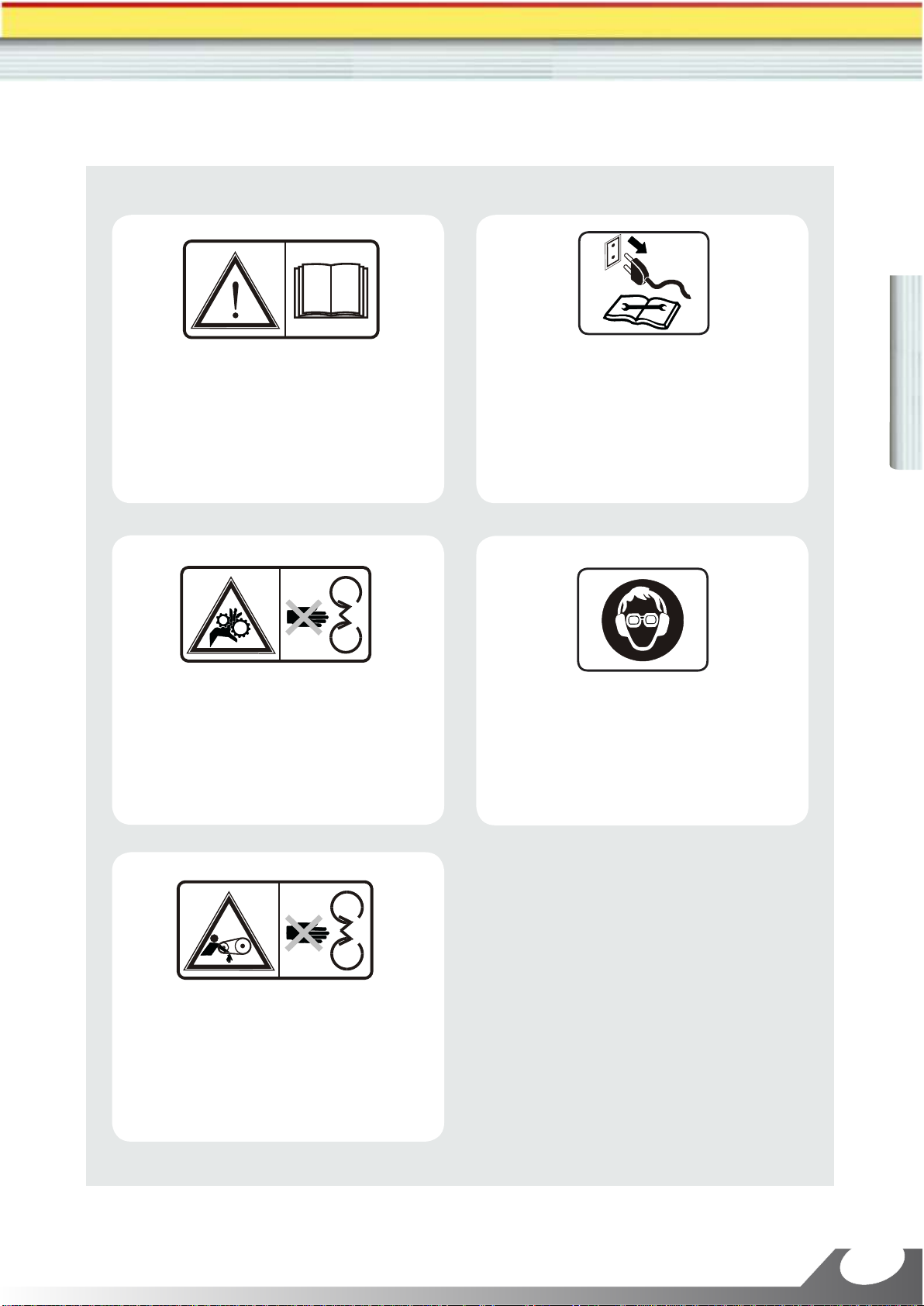

-Readthe instruction manual before turningonthe machine. Pay closeattentionand respect

alltheoperatingandsafetyrecommendationswhileoperating.SHARETHISINFORMATION

WITHOTHERUSERS.

-Donotoperatethemachinewhileorafterdrinkingalcoholicbeveragesormedicationswhich

affect your normal condition. Pay attention to what you are doing and use your good sense.

Anylackofattentionwhileoperatingthemachinecanresultinaseriousaccident.

-Disconnect thetractormotor beforeperforminganymaintenance jobonthemachine. Never

trytoperformanyrepairswhilethemachineisturnedon.Alwayspaycompleteattention!

-Beforeturningonthemachine,checkifthereareanytoolsorotherobjectsonit.

- Look around the machine before turning it on. Keep animals and spectators away at a safe

distance,awayforthepick-uparea.Beespeciallycarefulofchildren.

-Wearpersonalprotectiveequipment-PPE-whileoperatingthemachine.Exposuretonoise

forprolongedperiodcancausehearingdamageorloss.Wearearplugsandsafetyglasses.

-Neveropenthemachinewhenitisoperating.

- Never touch the belts or gears when the machine is operating. Keep your hands away from

movingparts.

-Dressappropriatelyforoperatingthemachine.Keeplonghairtiedupanddonotwearloose-

fitting clothing. Remove rings, chains, and any other objects which can become stuck in the

movingpartsormechanisms.

-Keepthesafetylabelsingoodconditionandlegible.Replacethemwhenevernecessary.

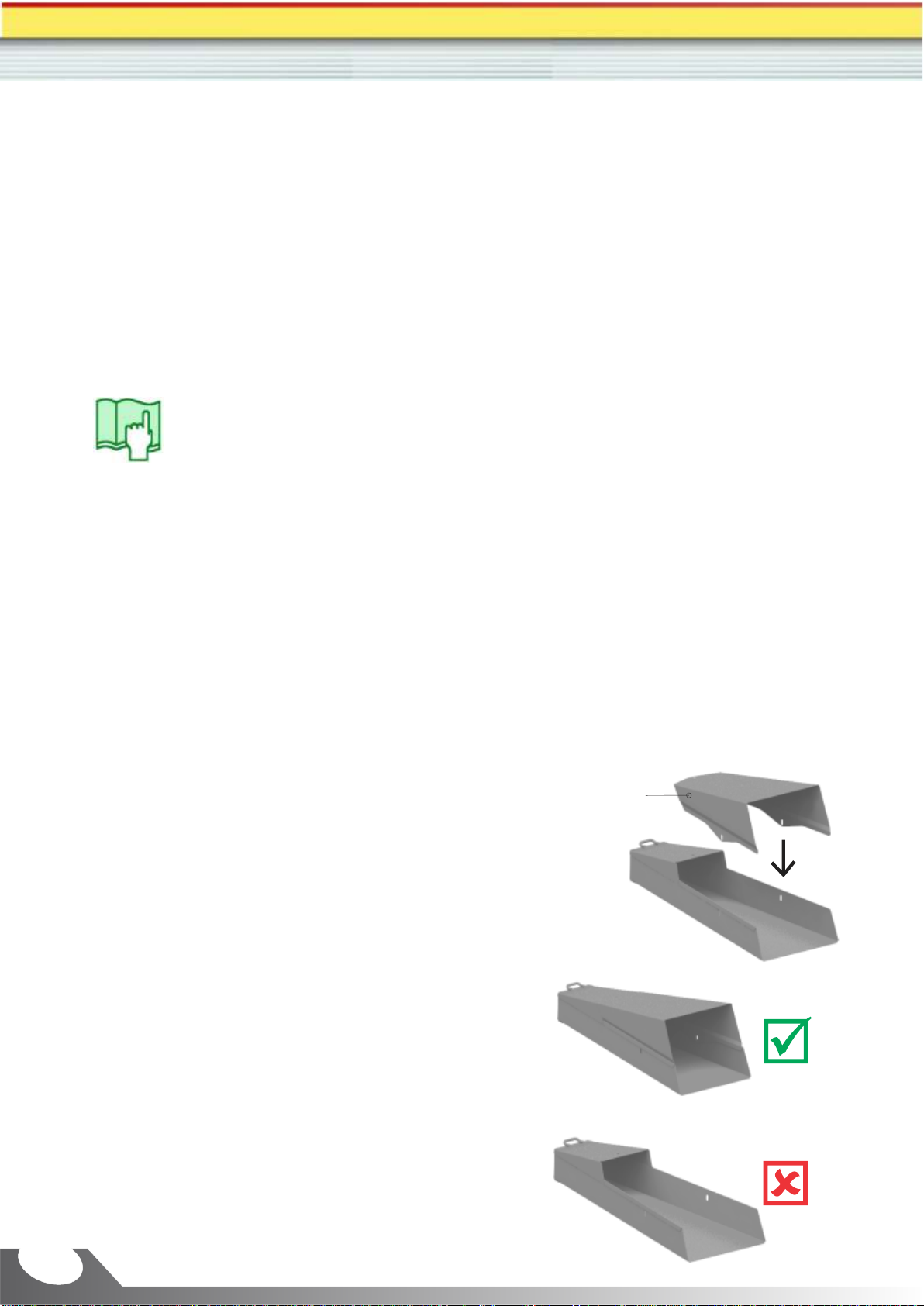

- Keep the shielding and protections in the proper places and do not operate the machine

withoutthembeinginstalled.

-Itis prohibited for peopleto stand on any partof the machine whileoperating. Whenever it is

necessary to get on the machine for any adjustment or repair, disconnect the power take-off

fromthetractorandwaituntilthecomponents/partsarecompletelymotionless.

-Nevertrytocleanorremoveproducts,strawetc.,whilethemachineisturnedon.Turnoffthe

motorandwaituntilallmovingpartsstopbeforecleaninganypartofthemachine.

- Never leave the machine operating when nobody is there.Always turn off the motor before

leavingtheoperatingarea.

- If you notice any abnormality in the operation: vibrations, different noises etc., turn off the

machineimmediately.Checkandeliminatethecausebeforeturningonagain.

- If it is necessary to work on the machine when it is raised by the hydraulic system, it must be

raised safely. Hydraulic mechanisms can lower without any reason or from leakage in the

system,andcauseanaccident.

-Donotplacethemachineoncementblocks,hollowbricks,orothersupportswhichcancrush

fromaprolongedweightload.

TECHNICAL MANUAL OF OPERATION - JF 30 EVO

English