PPM02-ALP-AUTOMATIC TWO ROWS POTATO PLANTER MACHINE USER GUIDE

1. PPM02-ALP-Automatic TWO ROWS

POTATO PLANTER

1.1. DESCRIPTION of THE MACHINE

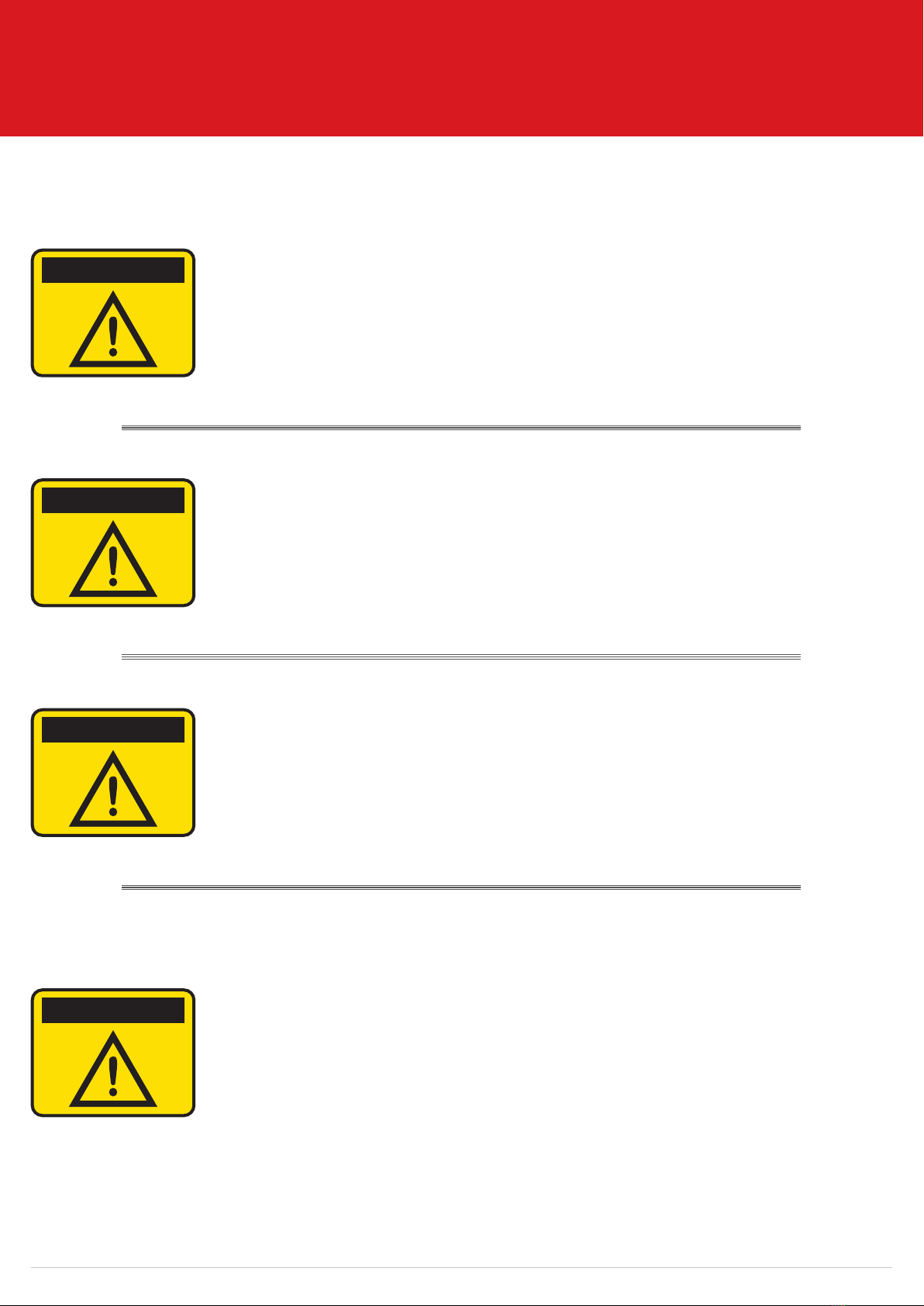

PPM02-ALP-Automatic is potato planter which has the capability of processing two rows by only one pass. It’s operational process

is as follows; Potato seeds in the hopper of machine drop down by gravity aand dropping ones are taken in side of seed cup sone

by one. The seed cupsa re mounted on a band-conveyor which moves on vertically. The band conveyor takes the movement from

transmission system which joint to the side Wheel. At the highest point of band conveyor, cupsa re started to turn down and seeds

are left the cups anda re dropped down in a metal hole. At the bottom of this hole, fixed legs are prepare the seed bed. Seeds drop

to the seed be done by one and in the best planting spaces. The machine takes power from side Wheel. It is semi-hanged equipment

which attached to tractor by it’s tri-point joint system (categories 1 and 2).

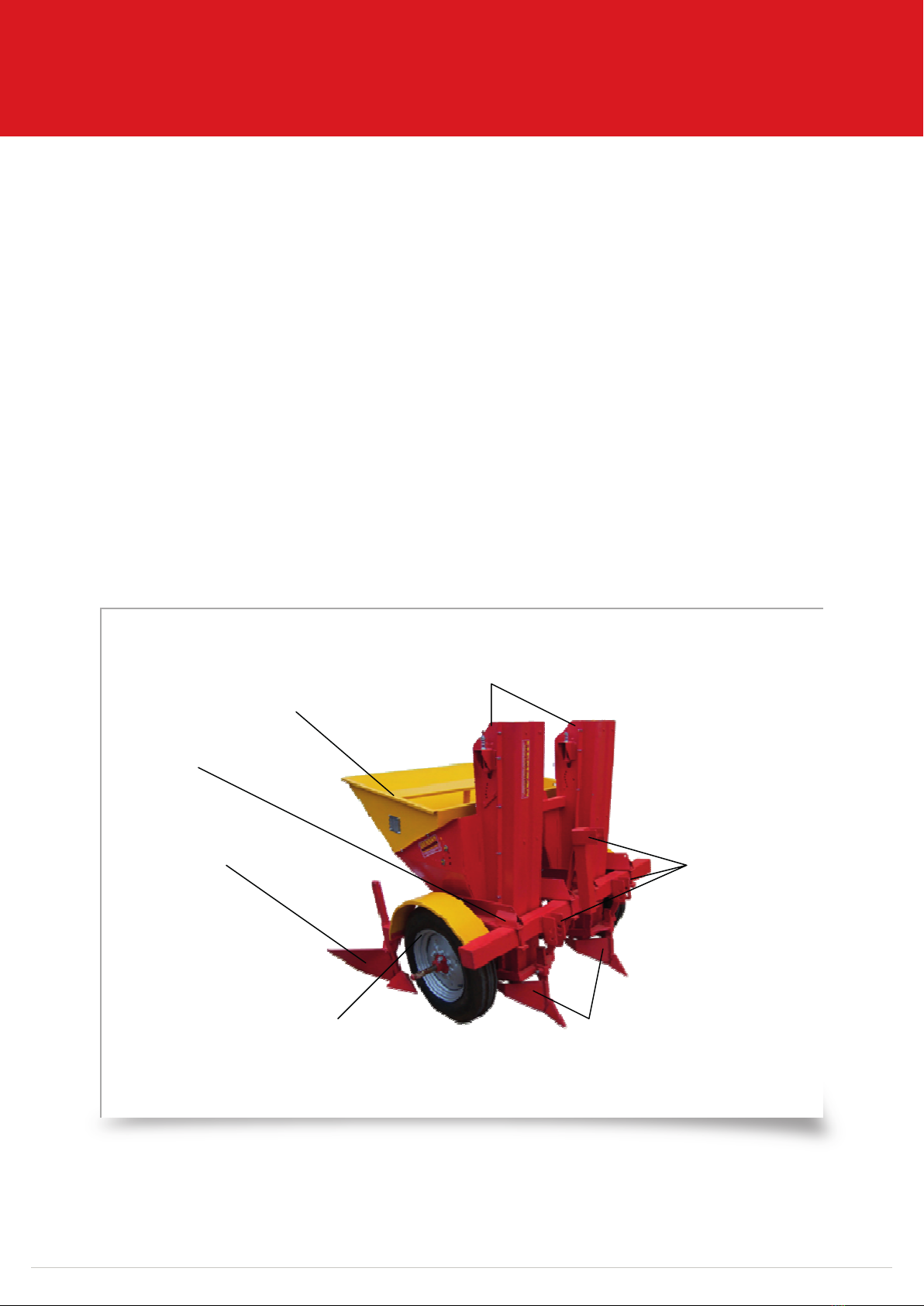

PPM02-ALP-Automatic consist of main frame, joint system, hopper, transmission system, cup conveyor, seedbed legs, covering

ploughs and side wheels. Main parts are illustrated at Figure 1.

1.2. MAIN PARTS of THE MACHINE

CUP CONVEYOR HOLES

MAIN HOPPER

MAIN FRAME

COVER LEGS

POWER WHEEL SEEDBED LEGS

JOINT SYSTEM

Figure 1

3www.alpler.com.tr