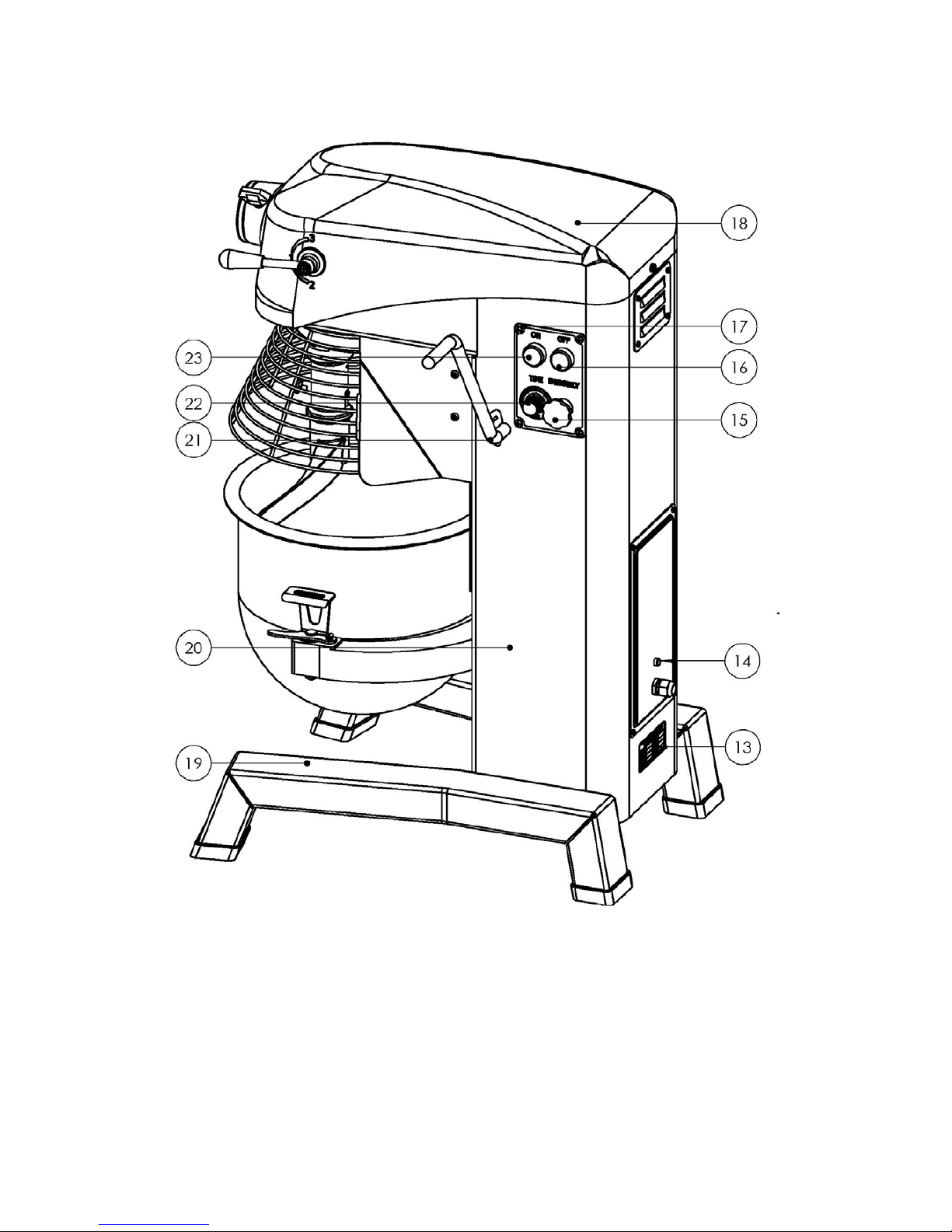

VIII Operating Instructions

1, Before use, one should check the power first to ensure that the use of the power is

supplied with the coordinated 13 parameters .Power outlet must be equipped with a

good grounding line for safety.

2,Installation of the Mixer: Lower the barrier to the minimum position by lifting the

21 handle,and place 8. Stirrer into 3. Run-Axis.

3, Barrel Installation: Lower the barrier to the minimum position by lifting the 21

handle,and 2 barrel, under the pressure of 7 Barrel Plate.

4, Transmission Shift: In order to better conservation of the machine, when speeding,

you should stop the operation first (by 16 Stop button) Then pull the handle to the

desired speed of 12Speed Handle, if not pull the running gear, it can be turned by

3. Run-Axis, but at the same time you must stop the machine operation.

5, Remove the Blender: Lower the barrier to the minimum position by lifting the 21

handle, and then pulled 9. Fixed Handle Mixer with a hand and remove 8.

Stirrer by the other hand.

6, the Start Operation: First, install 2 barrel, and then install the corresponding 8.

Stirrer, put the items needed to stir into 2. barrel , and then by 21.Lift Handle

to make 2. barrel to rise to a fixed position,(Turn 190 degrees counterclockwise), at

the same time close 11. Security Cover . Turn to the right speeding grade by

12Speed Handle and finally press 23. Start Switch to start running .

7, Shut Down Operations: After mixing items, press 16. Stop Button and the

machine stops running. Open 11. Security Cover.By lifting the 21 handle to

lower 2 barrel (about 190 degrees clockwise), then remove 8. Stirrer

(sometimes a lot of items are inside the barrel. If 8. Stirrer is not easily removed,

you can start removing some of the items within 2. barrel, then remove 8. Stirrer).

And then open 7. Barrel Plate, remove the 2 barrel.

8, Security Protection: For security reasons, the machine set the two devices. One is

15 emergency stop switch and the other is the 14. Overheat Protector. 15

emergency stop switch is to deal with issues encountered in the process of using,

press 15 emergency stop switch and you can quickly cut off the power to avoid

accidents. 14. Overheat Protector appears in the course of overload and the