S A F E T Y

Most accidents occur during work, maintenance or transport due to the non-observance of the

fundamental safety requirements. This is why you are the most important person for operating and

maintaining your rake. Regardless of whether you are working alone, with your family members or other

persons, always read and observe the basic method of operation. Additionally, warning labels are affixed

to the rake that serve as a reminder to always observe safety practices.

The indicated operation, maintenance and safety instructions must be strictly observed

at all times in order to ensure safe and secure rotary rake operation.

- Before beginning work, the operator must be aware of the functioning principle of all of the

mower components. It may be too late for this during work. Above all, learn to turn off the

machine safely and quickly in case of an emergency.

- The operation and maintenance manual must be kept for the entire service life of the machine.

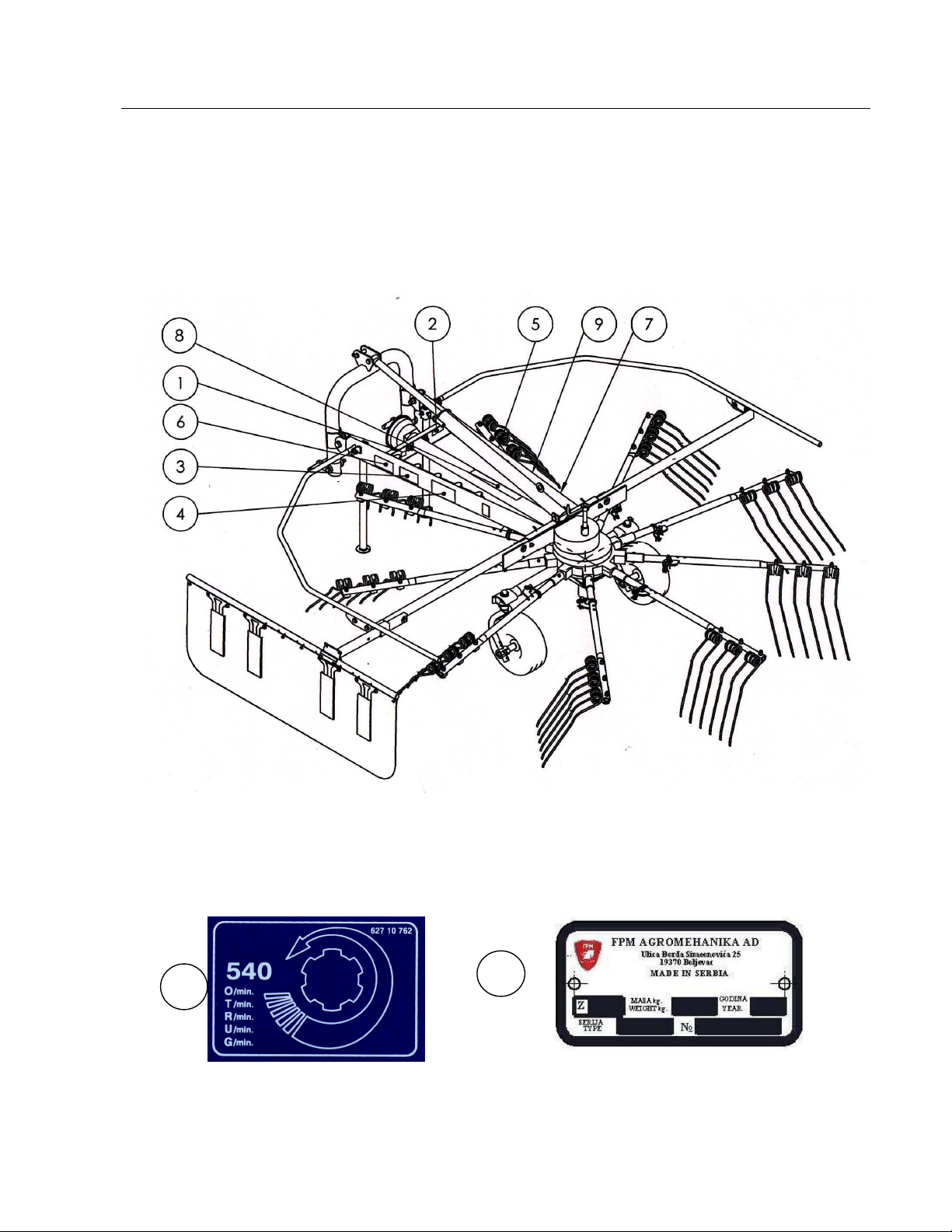

- The metal nameplate must always be legible, visible and clean.

- When attaching or detaching the rotary rake to or from the tractor, always put the support foot

in the appropriate position (safety).

- Be especially careful when attaching or detaching the rake to or from the tractor; the area

around the lifting device is dangerous.

- Check the tractor’s front wheels for damage prior to operation. Attach weights in the provided

place.

- Observe the maximum permissible axle load and total weight. Due to the added weight,

the load is redistributed on the wheel axles.

- Use a cab tractor for road safety requirements. Keep all windows closed during operation

in order to reduce the noise level.

- Prior to starting the rotary rake, even for a very short distance, always put it in the

transport position. Observe the permissible overall dimensions for transport.

- Prior to driving on public roads, secure the rake for safe transport

and observe the road traffic regulations.

- In special circumstances, use lights to signal danger, if not contrary to

road traffic regulations.

- Never transport others on the rake or the tractor during work or transport.

- Never transport an unsecured rotary rake.

- Never transport operating machinery.

- Never turn on the connection shaft when the rake is in the transport position.

- Never leave the driver’s seat while the tractor is operating.

- Every time before using the rake, check whether all parts (nuts, screws, etc.) are sufficiently

tightened, and in particular secure the spring tine brackets and spring tines.

Page 6