6

IV Responsibilities and liabilities of the user

The user is obliged to respect all instructions stated in the user guide, and relating to proper use, setting, maintenance, servicing, and stor-

ing of the product, as well as to carry out all actions intended for regular maintenance and servicing of the product at an authorised service

centre. In case of a problem occurring during use, they must immediately contact a distributor from which they purchased it or a nearby au-

thorised service centre. Also, the user must give for inspection a receipt and a warranty form to the distributor or an authorised service centre

in order to take advantage of warranty rights.

V Procedure for resolving complaints

The buyer and the distributor (seller) have a responsibility to ll in the warranty card correctly and send one copy to the address of FPM. This

form must be sent within 7 days from the date of purchase in order to conrm the warranty and ensure post-sale support.

The product’s fault must be reported within the warranty period to the distributor from whom the product was bought or at a nearby au-

thorised service centre within 30 days at most from the day when the problem occurred. In order to have rights under warranty, the user is

obliged to hand over the receipt and warranty card for inspection when delivering the defective product to an authorised service centre or

upon an authorised serviceperson’s visit.

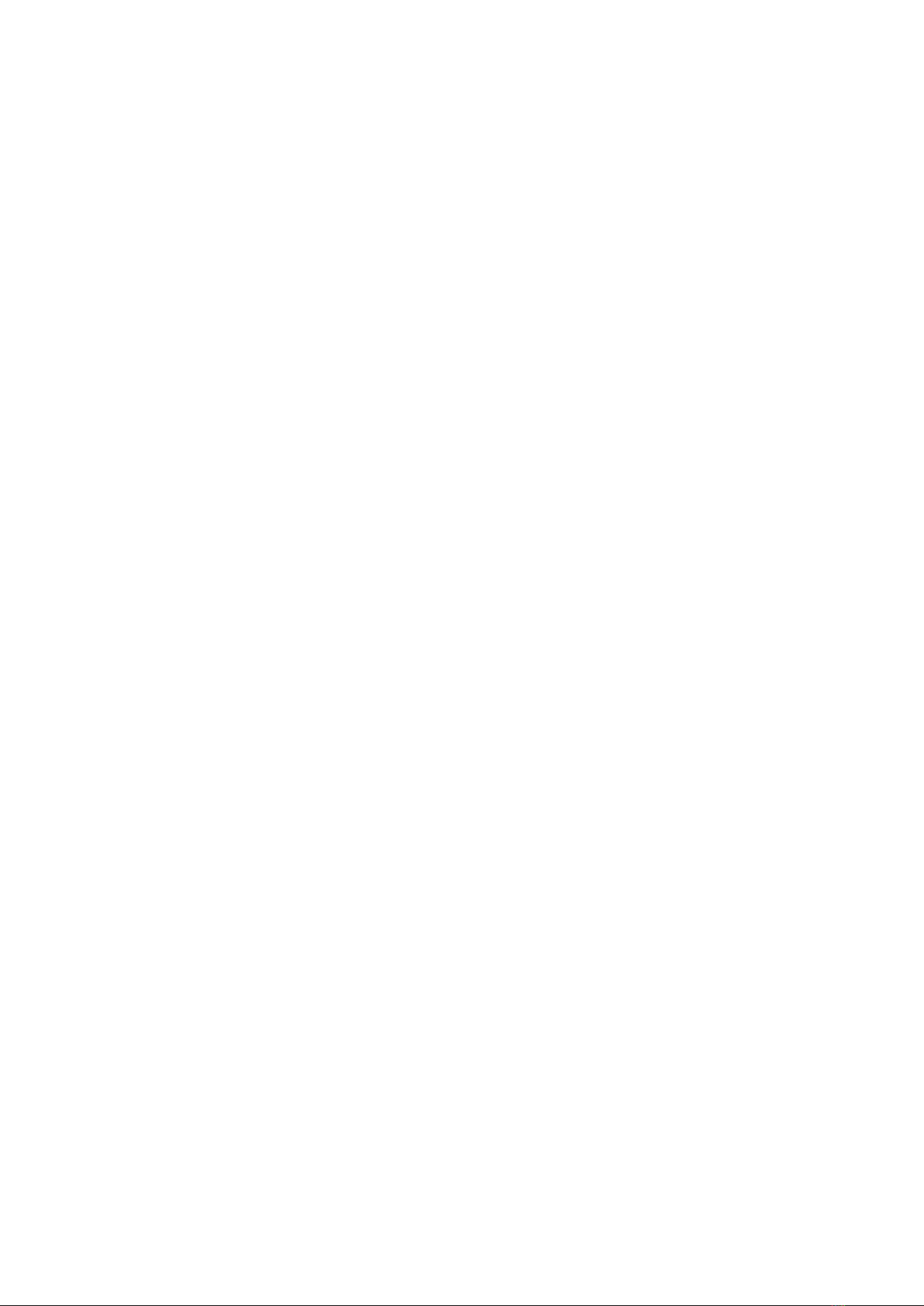

2. SAFETY WARNINGS

Safety warnings of a potential danger are indicated in two ways:

1. Recommendations for safe use in the manual;

2. Warning signed (labels) on the product.

2.1 Meaning of the warning signals

Symbols and warnings in this manual describe potential danger during use, inspection, or maintenance of the product and are divided into 4

groups according to the level of the potential danger. These warnings are intended to draw the user’s attention to be cautious for their own

safety and for that of people who are working with them. Failure to respect the instructions and warnings described may result in serious

injuries or, in the worst case, death.

DANGER! CAUTION!

WARNING!

2.2 Recommendations for safe use

2.2.1 General recommendations

1. The stated instructions for use, maintenance, and safety at work must be respected unconditionally in order to ensure safe and reliable

functioning.

2. Before starting work, the operator must be fully familiar with the functioning of all parts of the machine, and especially know how to

quickly and safely turn o the machine in case of danger.

3. Use a tractor with a cabin. Keep all windows closed during work.

4. Before starting the machine and during use, pay attention that other persons or animals are at a safe distance.

5. Never take other persons on the machine during work or transport.

6. While attaching or detaching the machine from a tractor, always move the leaning switch to the appropriate position.

7. Be especially careful while attaching or detaching the machine from a tractor.

8. Before use, check that the front tractor shaft is suciently weighted. Attach weights to the appropriate place if needed.

9. Pay attention not to exceed the permitted shaft load and total tractor weight, as specied by the tractor manufacturer.

10. Respect the prescribed and permitted dimension during transport.

11. Before beginning transport on public roads, be sure to insure the machine for a safe drive, label it appropriately, and respect public

trac rules.

12. Before transporting the machine on public roads, be sure to set it into the transport position as explained in this manual.

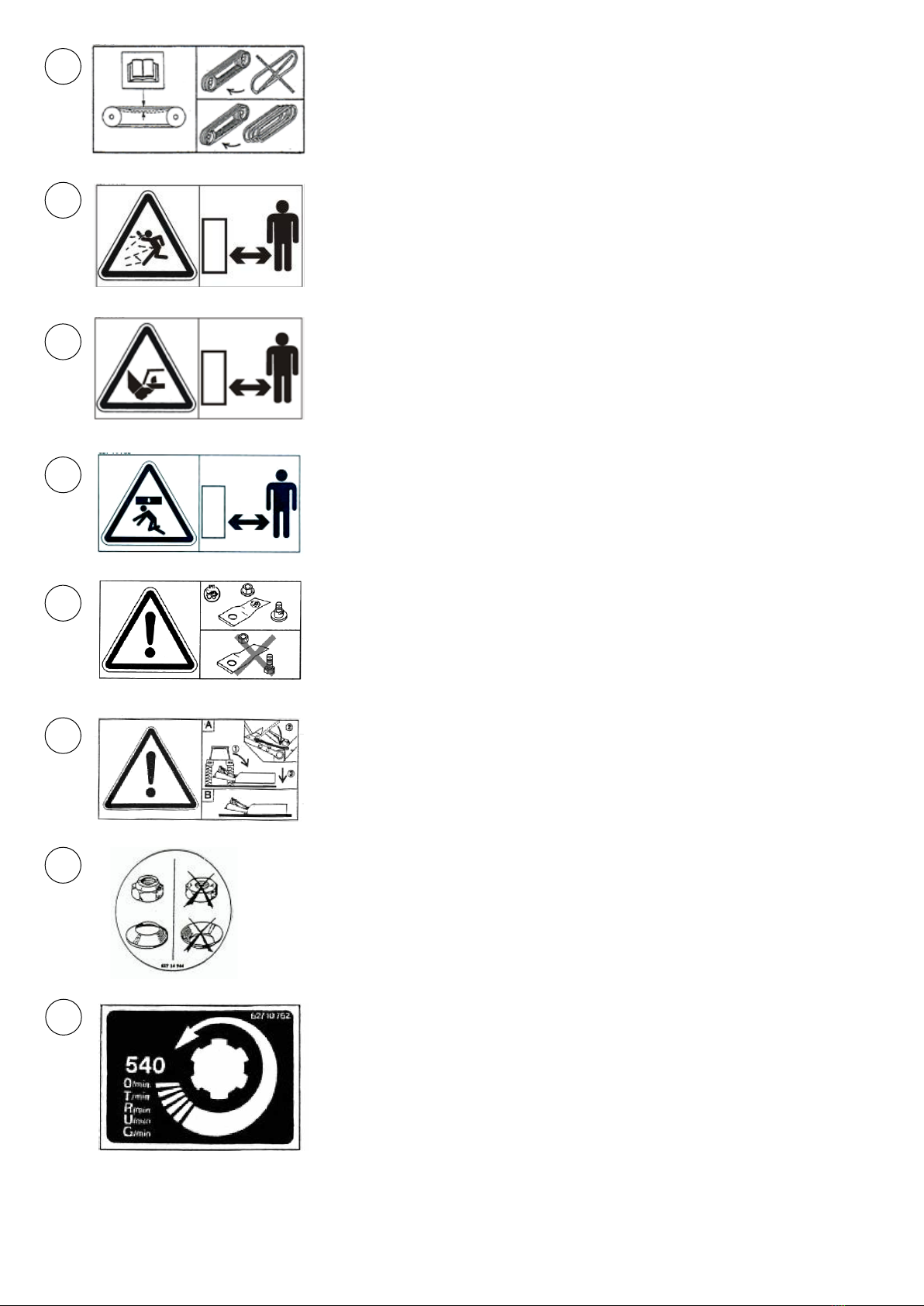

13. Never turn on the joining axle of the tractor while the machine is in the transport position.

14. Never leave the driver’s seat while the machine is operating.

15. Adjust the speed of motion to working conditions and conditions on the road. Always avoid sudden changes of direction.

16. Be especially careful while turning and keep the machine’s dimensions in mind.

17. Remove all foreign objects from the working area (the eld), which can damage the machine and endanger your safety.

18. Before you leave the tractor or before making adjustment, repairs, or maintenance of the machine, put the machine on the ground,

turn o the Cardan joint power, turn o the tractor engine, take out the key, and pull the tractor parking brake.

19. Do not stand between the machine and the tractor unless the tractor parking brake has been pulled and/or wedges are placed under

the wheels.

20. Before making any adjustments, repairs, or maintenance of the machine, make sure the machine does not accidentally move.

NOTE

Indicates a high-risk situation which, if not

avoided, could lead to serious injuries or

death.

Indicates a potentially dangerous situation

which, if not avoided, could lead to serious

injuries or death, as well as material damage.

Indicates a potentially dangerous situation

which, if not avoided, could lead to material

damage and minor injuries.

Indicates general indications and tips for safe,

proper, and ecient use of the product.