FRANCO srl Manual of use and maintenance ROOF COOLER

INDEX ......................................................................................................................................1

1 - INTRODUCTION.................................................................................................................3

1.1 General warnings............................................................................................................3

1.2 Instructions for proper disposal of the product................................................................3

1.3 Covenants used throughout this manual ........................................................................4

1.4 Conservation of the instruction manual...........................................................................4

1.5 Recipients.......................................................................................................................5

1.6 Glossary and pictographs...............................................................................................5

1.7 Applicazioni.....................................................................................................................9

1.8 Versions..........................................................................................................................9

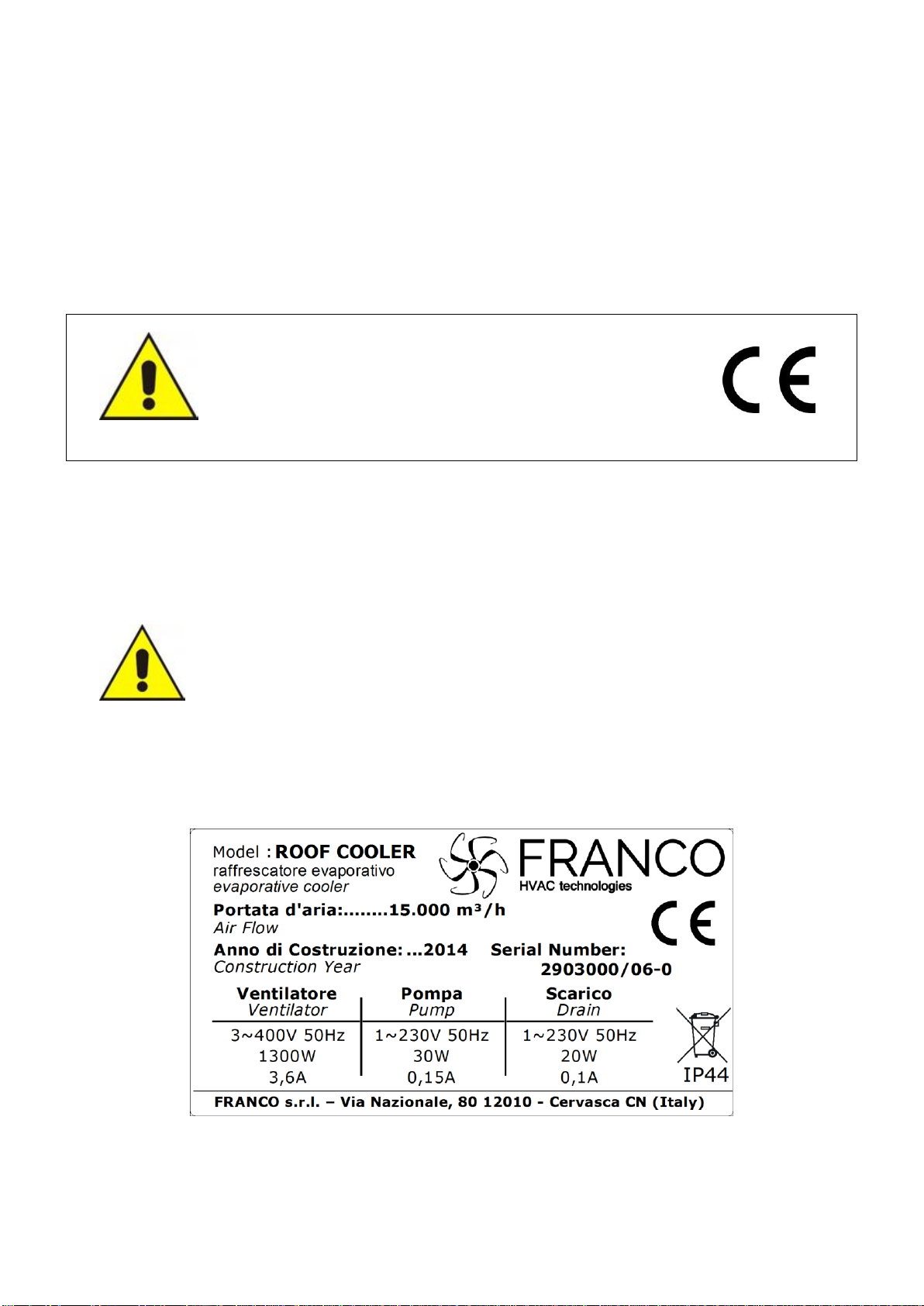

1.9 Identification and data label of the unit ...........................................................................9

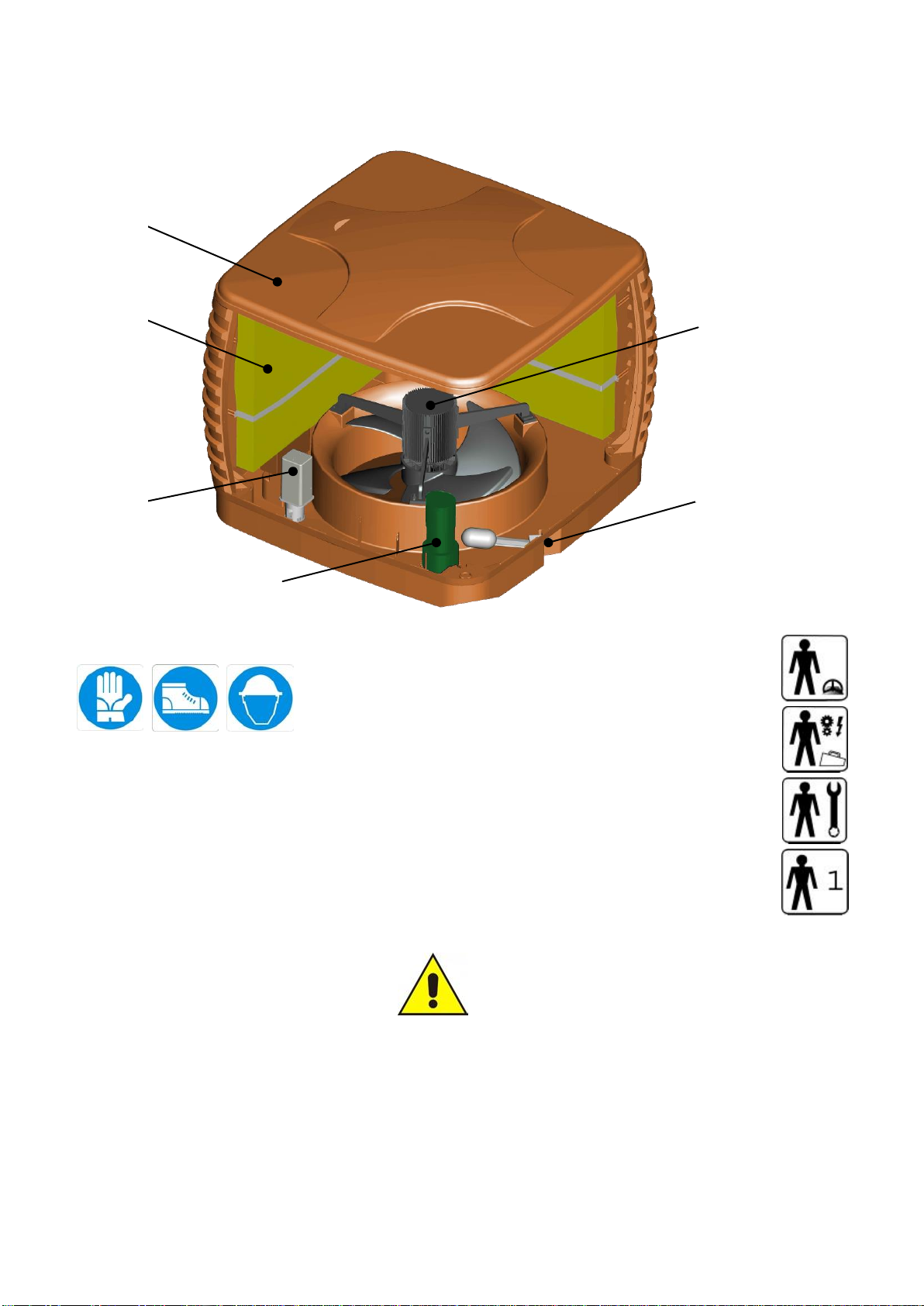

1.10 Description of the parts...............................................................................................10

1.11 Transport and handling...............................................................................................10

1.12 Warranty.....................................................................................................................11

1.13 Statements..................................................................................................................11

1.14 Declaration of conformity............................................................................................12

1.15 Declaration of incorporation........................................................................................ 13

2 - INSTALLATION................................................................................................................ 14

2.1 Before installing............................................................................................................ 14

2.2 Positioning....................................................................................................................14

2.3 Electrical connection.....................................................................................................15

2.4 Hydraulic connection .................................................................................................... 15

3 - OPERATION..................................................................................................................... 16

3.1 Getting started..............................................................................................................16

3.2 First start.......................................................................................................................16

3.3 Starting ......................................................................................................................... 16

3.4 Optimum conditions of usage .......................................................................................17

3.5 Water Drainage (bleed-off) ...........................................................................................17

4 - MAINTENANCE................................................................................................................ 18

4.1 Cleaning the panels......................................................................................................18

4.2 Cleaning the tank..........................................................................................................18

4.3 Replacing the pump...................................................................................................... 18

4.4 Replacing the float........................................................................................................18

4.5 Replacing the exhaust ..................................................................................................18

4.6 Replacing the panels ....................................................................................................18

5 - TECHNICAL SPECIFICATIONS ...................................................................................... 19

5.1 Technical data ..............................................................................................................19

5.2 Wiring............................................................................................................................20

5.3 Spare parts...................................................................................................................21

6 - PROBLEMS AND SOLUTIONS ....................................................................................... 23