Page 3

MT04-001 AquariTherm Tap (Manual) www.dartvalley.co.uk

Revision No. MAQTIN16071301

Page 2

MT04-001 AquariTherm Tap (Manual) www.dartvalley.co.uk

Revision No. MAQTIN16071301

The control box should be located in a dry location and not

exposed to dirt, dust or damp. The unit should be accessible when

required, but not within easy reach of unauthorised persons.

It will be necessary to make adjustments and service the control

box after installation, and in the future. Secure access areas and

duct spaces are recommended.

The control box is not designed for direct surface mounting into

washroom areas. Never open the cover with the supply live.

The routes that cables will take when connecting external

equipment to the control box should also be planned at this stage.

The bath control system is typically used with a bath filling back

plate or spout

Important: Thermostatic mixing valve

It is recommended that hot water is supplied through an approved

TMV3 thermostatic mixing valve to prevent scalding (sold

seperately).

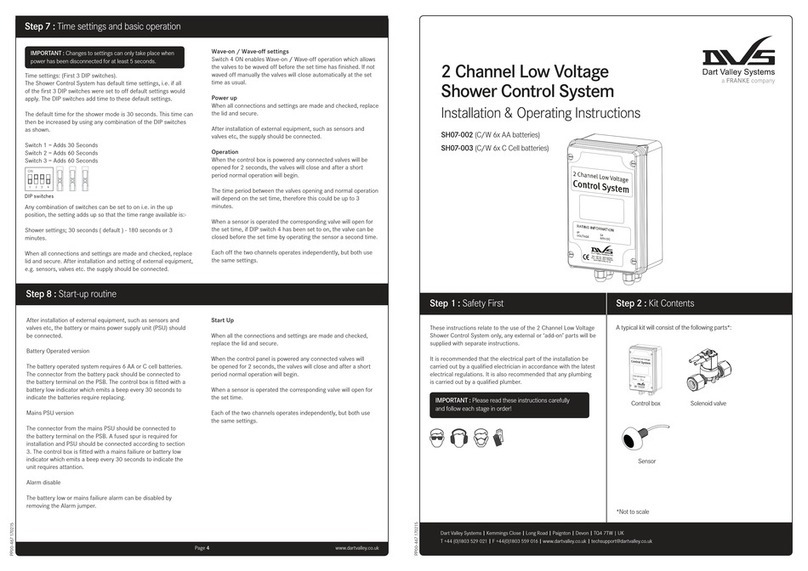

Step 3 : Typical installation

Step 2 : ContentsStep 1 : Safety First

These instructions relate to the use of the Bath Control System

only, any external or ‘add-on’ parts will be supplied with separate

instructions.

It is recommended that the electrical part of the installation be

carried out by a qualified electrician in accordance with the latest

electrical regulations. It is also recommended that any plumbing

is carried out by a qualified plumber.

*Not to scale

IMPORTANT : Please read these instructions carefully

and follow each stage in order!

IMPORTANT : It is recommended that hot water is supplied

through an approved TMV3 thermostatic mixing valve (sold

seperately), in order to prevent scalding.

Step 5 : Fixing & wiring

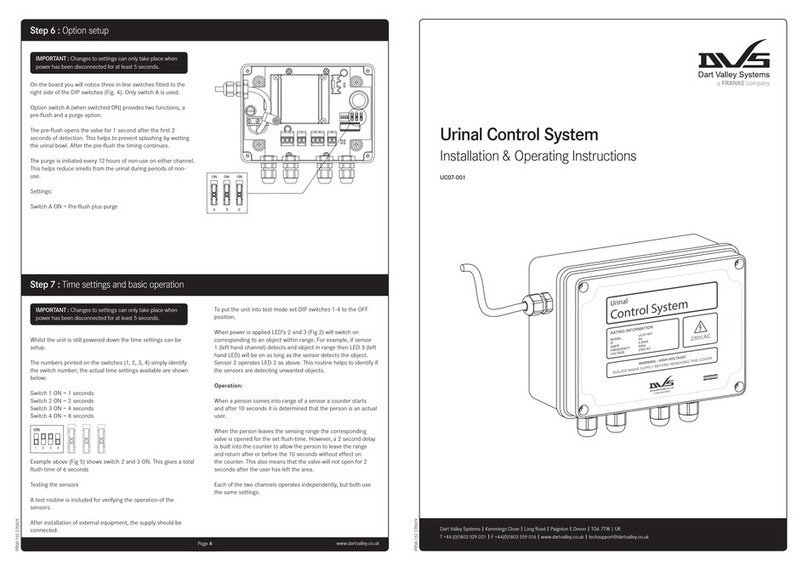

Step 4 : Board layout

Input connection - Sensor 1

Output connection - Valve 1

Input connection - Sensor 2

Output connection - Valve 2

Cable entry - Sensor 1

Cable entry - Valve 1

Cable entry - Sensor 2

Cable entry - Valve 2

Mains supply

Time setting switches

Option switches

LED 1 - For engineers / testing only

LED 2 - For engineers / testing only

LED 3 - For engineers / testing only

Fuse (replace with exact same type)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

915 12 10 11

14

13

43876521

DO NOT extend cables

DO NOT leave badly fitted cables

DO NOT interfere with the mains flex

DO check all cables and connections

DO ask for advice if / when necessary

The box should be securely fixed in a suitable location in a

horizontal orientation, so that the front label is read correctly.

Remove lid to expose four fixing locations around the edge of the

enclosure (see Fig. 3). These areas allow the fastening of the unit

without removing the printed circuit board.

Drill through these marked areas away from the wall to avoid dust

entering the control box, then hold control box in position against

the wall and mark holes with a pencil. Remove box, drill and plug

marked areas and fix the control unit with suitable fixings.

Connect the mains supply lead to a 230V ac supply via a fused

spur, the fuse rating should be 3 Amps. The mains supply should

NOT be initiated until all external equipment has been installed

and wired.

Always read instructions supplied with external components and

ensure that only the supplied equipment is connected to the

control box.

Cables should enter the enclosure through the cable glands. Keep

all connections tidy and do not allow cable to finish or hang in the

transformer area.

It is recommended that each cable is fed through the relative

cable gland into the enclosure; the cable can then be pulled out

towards the fitter to allow the connector plugs to be fitted.

The connector plugs can be disconnected from the mating

sockets when wiring external equipment, double check positions

with the plug orientations as they only fit one way!

When each plug has been wired the cables can be pulled back

through the cable glands, and the plug re-connected to the

corresponding socket. Cables should not be left to torte or slack.

When all connections are made and checked, replace the lid and

secure.

Fixing locations

Fuse

Connector plug

Fixing screw

Control box

Bath Control System box only*:

Always isolate

power when

opening the

control unit!

3 AMP

fused

spur

Bath

control

system

Solenoid

valve

TMV3

Spectrum

backplate

Spouts

Sensors

Cold

Hot Bath

(Spare Secondary Fuse Included)

IMPORTANT : The control should be connected to a clean,

dedicated mains supply, via a 3A rated spur