4

Disclaimer

Since Frankford Arsenal has no control over the choice of reloading components

(ie., cases, bullets, primers, and powder), the manner in which they are assembled,

the use of the press, or the firearms in which the resulting reloaded ammunition

may be used, no responsibility, either expressed or implied, is assumed for the use

of ammunition reloaded with this press.

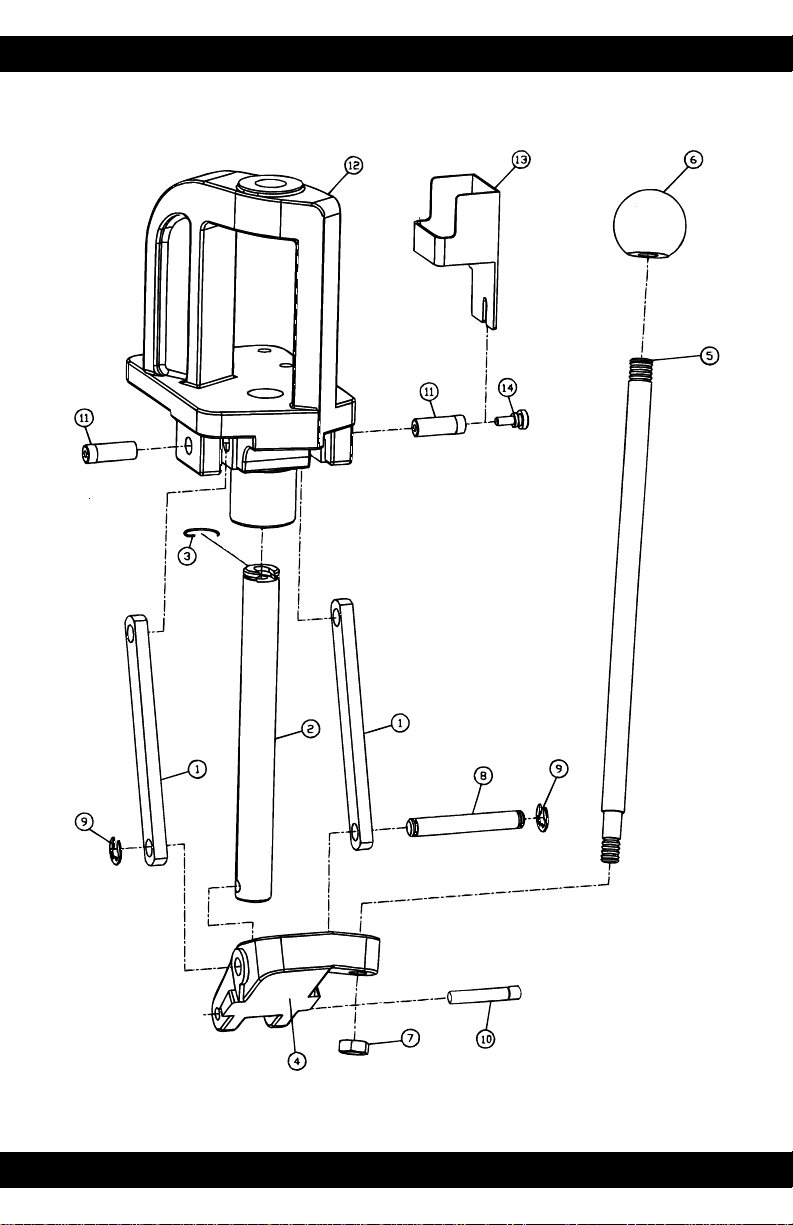

Mounting and Assembly

Your new Frankford Arsenal reloading press is shipped completely assembled and ready to use

with the exception of the operating handle and primer catcher. Prior to use, the press should

be securely mounted to a solid bench. The bench top should be rigid and at least 3 4” thick.

Mount and assemble the press as follows.

• Carefully position the press against the edge of the bench top in a convenient location.

The back of the ram support column and link arm supports should be flush with the

edge of the bench top. The press frame bottom should also set flush against the bench

top.

• Verify that the toggle block will not interfere with any portion of the bench

throughout its entire range of motion.

• With the press in the desired mounting location, mark the position of the mounting

holes using a pencil or punch.

• Remove the press and drill the 3 mounting holes in the bench top using a 3 8” drill bit.

• Secure the press assembly to the bench with the three 5 16” bolts (provided) using

1 2” box end wrenches or sockets. Be sure to use the flat washers (provided) above the

press frame and below the bench top.

• Slide the handle assembly into the hole in the toggle block . Secure the handle with the

1 2”-20 jam nut using a 3 4” box end wrench or socket.

• Screw the 1 4”-20 nylon thumbscrew into the threaded hole in the right side, upper

link pin. Back out the thumbscrew slightly. Slide the primer catcher slot downward over

the thumbscrew, with the primer catcher box facing the ram, until the primer catcher

rests firmly against the top of the frame. Secure by hand tightening the thumbscrew.

Do not over-tighten.

Maintenance and Lubrication

The press has been lubricated at the factory and is ready for use. However, the ram and link

pins should be lubricated periodically with SAE 30 weight motor oil or equivalent. Never use

penetrating lubricants, aerosol sprays, or solvent type lubricants, such as WD-40™ or Break

Free™. The press should be cleaned prior to lubrication to remove grit and other residue. If

rust spots appear on unpainted surfaces, swab with gun oil and wipe dry. If the press is to be

used in a damp area, all non-painted surfaces should be protected with a thin film of oil.

Painted surfaces may be cleaned with a damp cloth.

The primer catcher should be emptied periodically. Wipe away any accumulated grit and

primer residue from around the ram as well as any accumulations within the primer ejector slot

of the ram. Wipe up any excess oil that may also accumulate in the primer ejector slot.