PRO-S Rev1104

2

CONTENTS Table of Contents

CONTENTS ............................................................................................................... 2

List of Tables ......................................................................................................... 3

List of Figures........................................................................................................ 3

INTRODUCTION...................................................................................................... 4

Overview ................................................................................................................ 4

Features.................................................................................................................. 4

Specifications......................................................................................................... 5

GENERAL DESCRIPTION....................................................................................... 7

Components .......................................................................................................... 7

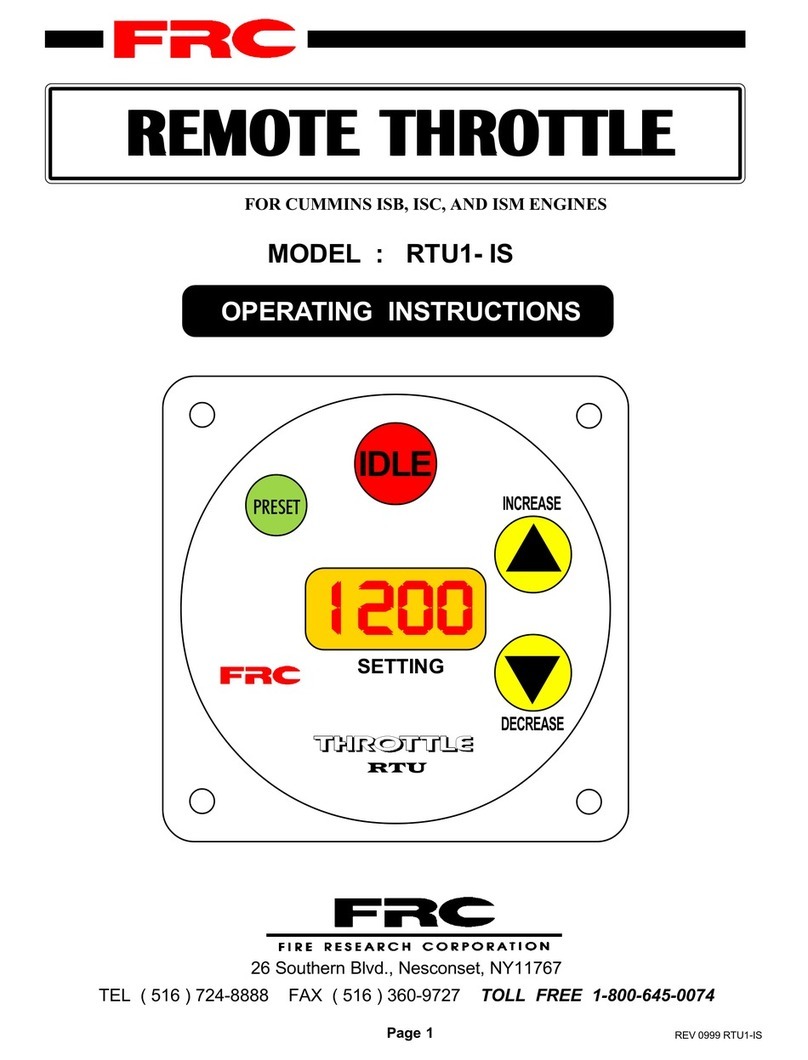

Controls and Indicators ......................................................................................... 8

INSTALLATION ...................................................................................................... 10

Install Control Module ......................................................................................... 10

Install Pressure Transducer.................................................................................. 11

Install Throttle Servomotor (Non-Electronic Engine Only) ................................. 12

Install Optional High Idle ..................................................................................... 14

OPERATION............................................................................................................ 15

Pressure Mode Operation.................................................................................... 16

RPM Mode Operation ......................................................................................... 17

Change Preset Setting (Pressure or RPM)........................................................... 17

System Options ................................................................................................... 18

CALIBRATION........................................................................................................ 19

RPM Calibration (PRO-S 3, 6, and 8)................................................................. 19

High Idle Option Calibration................................................................................ 20

3rd Gear Lock-up RPM Calibration (Ford 6.0L) ................................................ 20

DIAGNOSTICS ....................................................................................................... 21

WIRING ................................................................................................................... 22

Power................................................................................................................... 22

HighIdle .............................................................................................................. 23

Pressure Transducer ............................................................................................ 24

Common OME Connectors ................................................................................ 25

Cummins PRO-S 1 Cables .................................................................................. 26

Cummins Harness Connections........................................................................... 27

Detroit Diesel (Series 50 and 60) PRO-S 2 Cables.............................................. 30

Detroit Diesel (Series 50 and 60) Harness Connections ...................................... 31

Non-Electronic Engine PRO-S 3 Cables ............................................................. 32

Non-Electronic Harness Connections.................................................................. 33

Navistar and Detroit Diesel (Series 40) PRO-S 4 Cables .................................... 34

Navistar and Detroit Diesel (Series 40) Harness Connections ............................. 35

Caterpillar PRO-S 5 Cables................................................................................. 36

Caterpillar Harness Connections.......................................................................... 37