FR500D Series Special Purpose Inverter for Elevator

- 10 -

Chapter 2 Commissioning guide

FR500D series designed special for elevator application supports open loop & close loop vector

control as well as below functions:

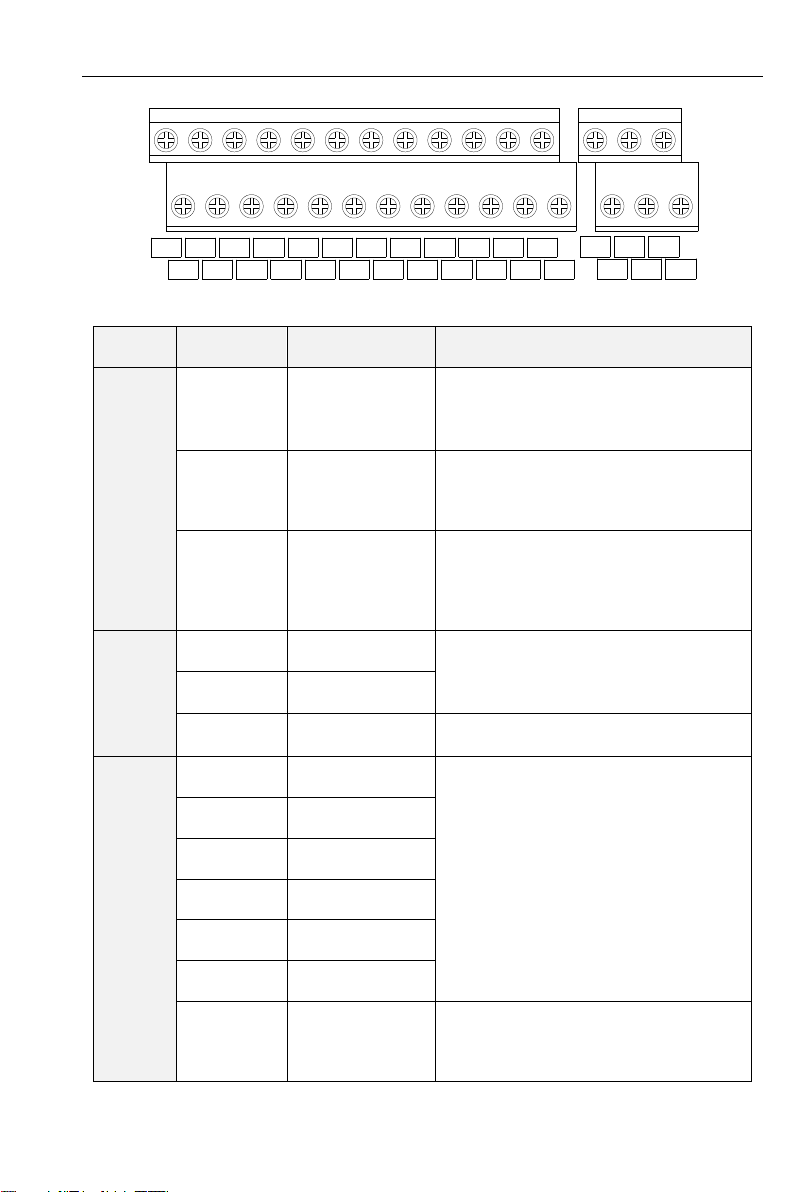

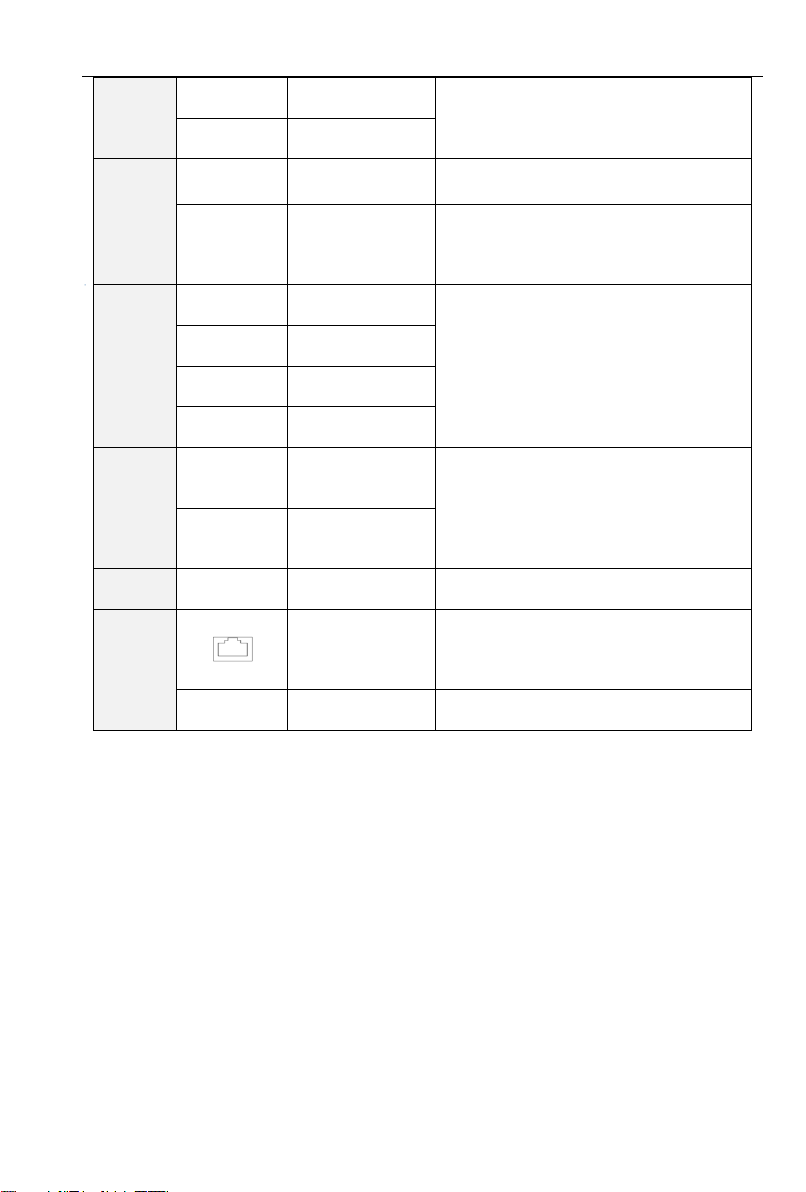

2.1 Single multi-step speed terminal elevator controller

The high speed and leveling speed is controlled by high speed terminal’s on-off, the wiring is as

below

R

T

U

V

WM

R1A

R1B

R1C

DI1

Up

Brake

FR500D

S

3-Phase 380VAC

DI2

Down

DI3

High Speed

DI4

DI5

Inspection

R2A

R2B

R2CKM2

KM2

DI6

Base Block

+ PB

Resistance

24V

Y1

DI7

COM COM

Fault

Elevator

Controller

KM1

Fig. 2-1 Wiring of single multi-step speed terminal elevator controller

To complete the wiring of controller, elevator and motor, no need R2 & Y1 wiring if the controller is

without operation contactor (KM20) and fault signal receive. Then commissioning procedure as below

1,To set high speed and leveling speed, which are switched through one high speed terminal,

setting parameter as below:

F12.00= Leveling speed

F12.01=High speed

2, To set maintenance speed. Maintenance speed and leveling speed will be common in some

elevator controllers, if no maintenance signal output, no need wiring for maintenance; If maintenance

signal output available, the speed can be set via function code

H00.13=Maintenance speed

3,Base block signal, no need wiring of base block if base block signal is not available in elevator

controller; If base block is available, most of elevator controllers provide normally closed signal, if so

need to set DI7 in anti-logic as below

F04.14=00010

4,Maintenance operation testing, the elevator controller switched to maintenance operation mode,

and press LIFT UP or LIFT DOWN to check if the running direction is consistent. If not, exchange UP

and DOWN signal line, means exchange DI1 & DI2 signal lines