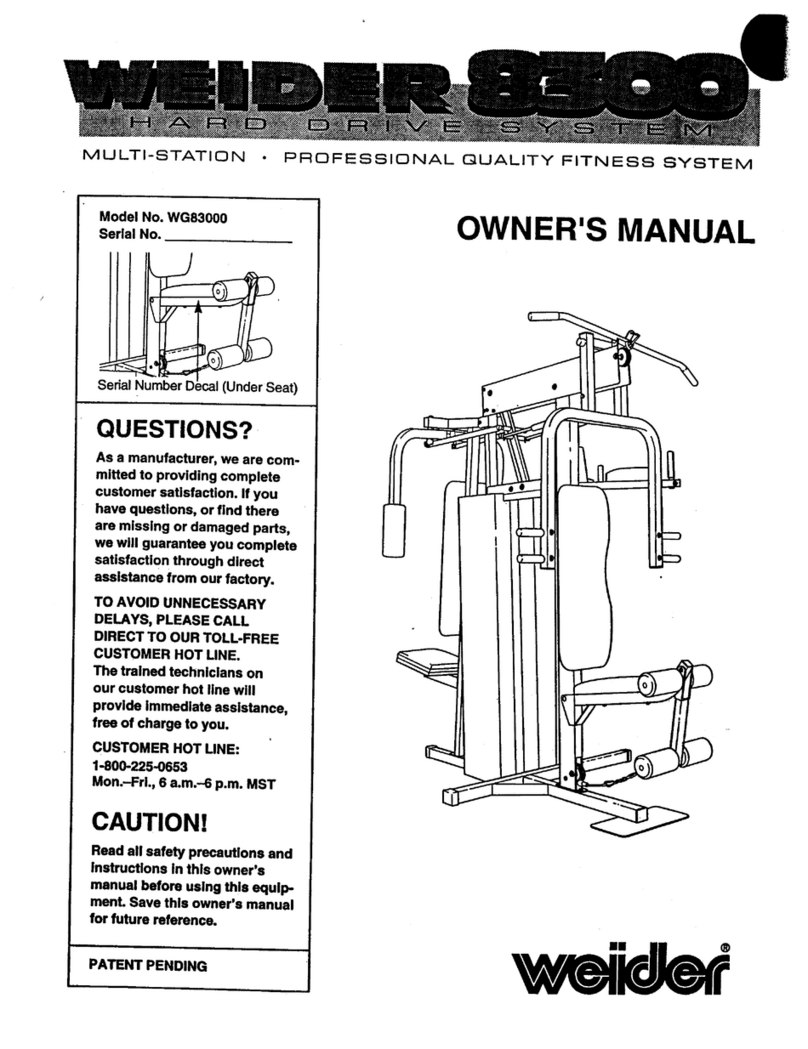

•Sealed bearing pulleys

•Multi-grip chin up bar with comfortable knurling

•6 weight storage post

•High tensile 2000 lbs cables

•Adjustable dual pulley system (16 levels)

•Smith Machine with 12 adjustable heights. High

tension 2000 lb cross cables with 16 adjustable

heights. (16 levels1:1 pull ratio)

TECH SPECS

•Max Load (J Hooks): 440 lbs

•Max Load (Bar Catches): 550 lbs

•Max Load (Smith Bar): 500 lbs

•Max Load (Plate Storage): 500 lbs

•Max Load (Pull Up Bar): 1000 lbs

•Commercial frame 813 lbs (369 kgs)

•Total Weight Stack: 660 lbs (300

kgs); 330 lbs per side

•1:1 Ratio Pulley System

•Cables extends 54"

WARRANTY

•Lifetime Parts and 1 Year Labor Warranty

FEATURES

ACCESSORIES INCLUDED

•Stirrup Handles

•Adjustable Dual Dip Bars

•Lat Bar

•J Hooks

•Bar Catches

•Landmine Attachment

•86" Olympic Smith Bar

•Lat Pull Knee Cushion

(latches on to support you

at the knees for lat pull

downs)

•Vertical Leg Press Plate

•Weight Stack Increments: 15 lbs

(22 Plates per side)

•Weight: 992 lbs (450 kgs)

Footprint: 49" x 58" (with that

landmine attachment).. 51.5"

without landmine (Actual floor

space meaning parts that sit and

touches floor)

•Dimensions: 65"D x 86"W x

90.1"H