RXB PLUS ROTARY SCREW COMPRESSOR UNITS

INSTALLATION - OPERATION - MAINTENANCE

S70-101 IOM

Page 2

GENERAL INFORMATION

Preface .............................................................................. 3

Design Limitations ............................................................. 3

Job Inspection ................................................................... 3

Transit Damage Claims ..................................................... 3

Compressor/Unit Identification .......................................... 3

INSTALLATION

Foundation......................................................................... 4

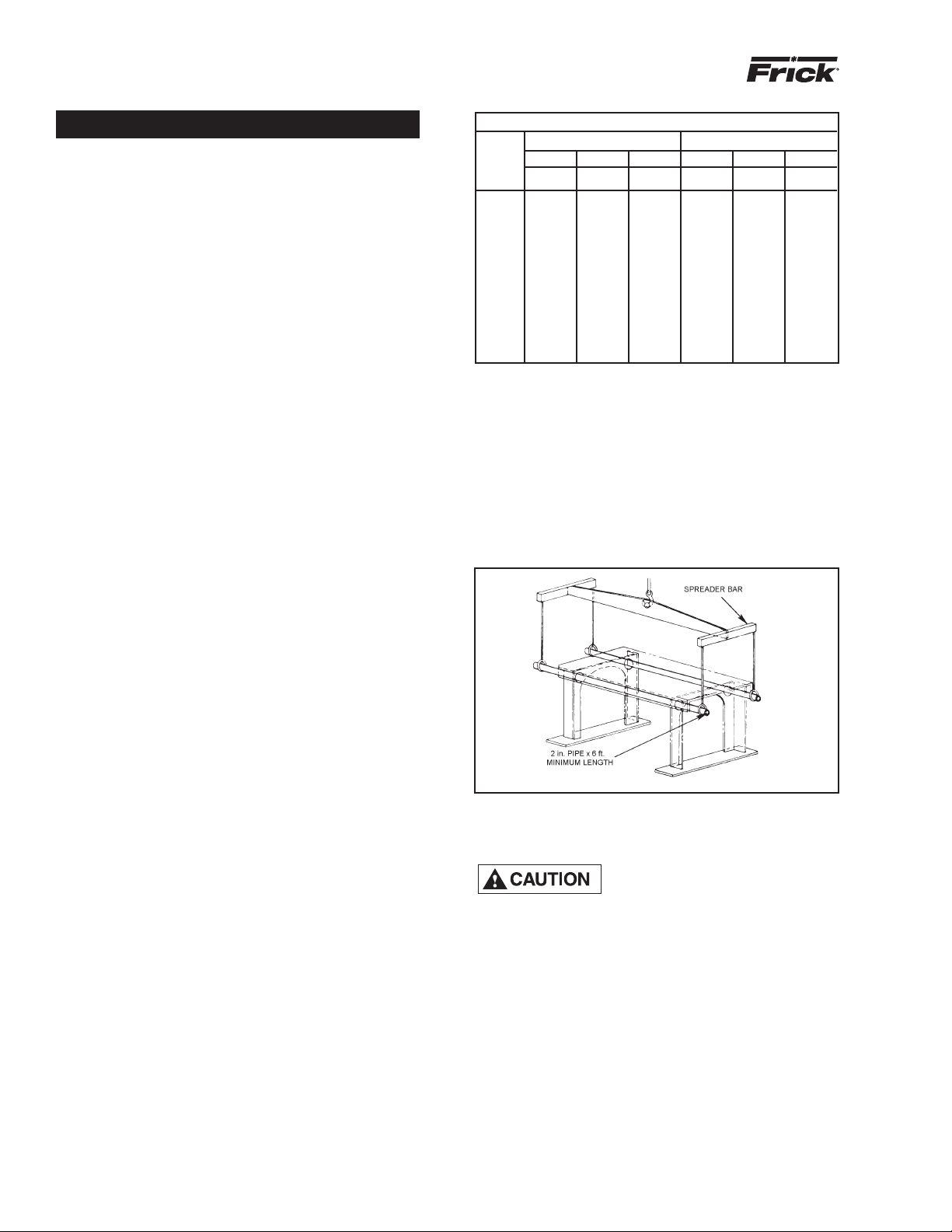

Handling and Moving......................................................... 4

Skid Removal .................................................................... 5

Motor Mounting.................................................................. 5

Compressor/Motor Coupling Installation ........................... 5

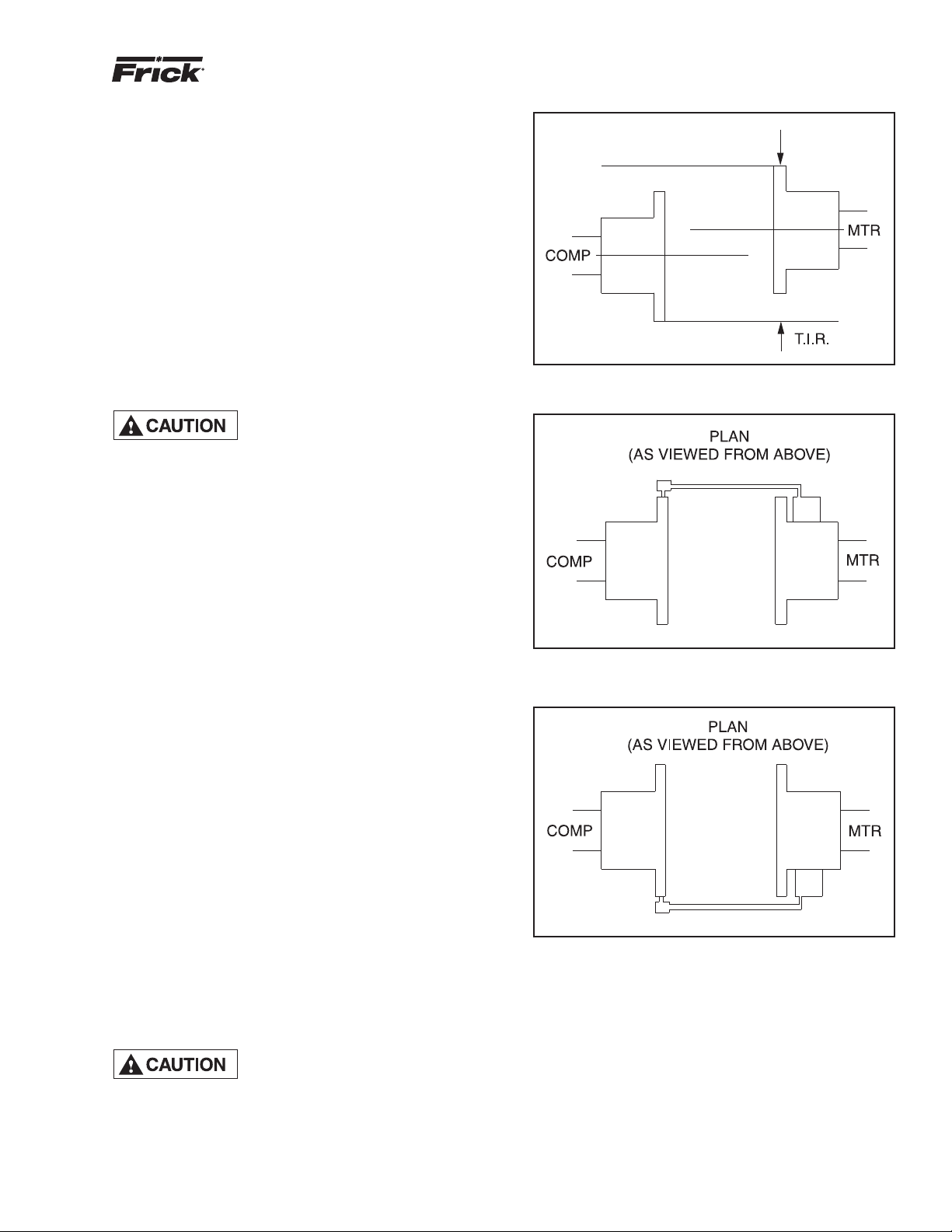

Coupling Alignment Procedure.......................................... 6

Hot Alignment of Compressor/Motor ................................. 8

Checking Motor/Compressor Rotation .............................. 8

Holding Charge and Storage............................................. 8

Compressor Oil.................................................................. 8

Oil Charge ......................................................................... 8

Oil Heater .......................................................................... 8

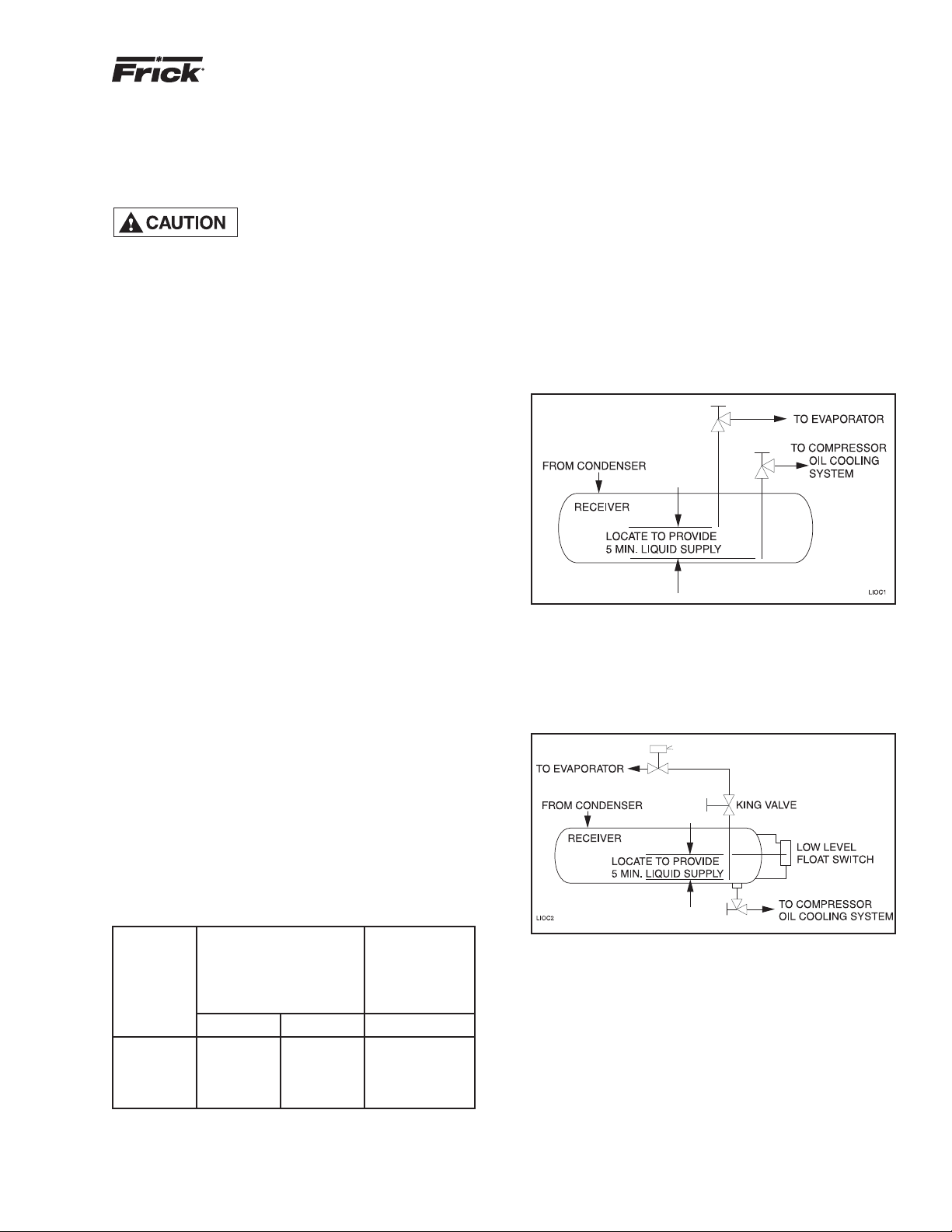

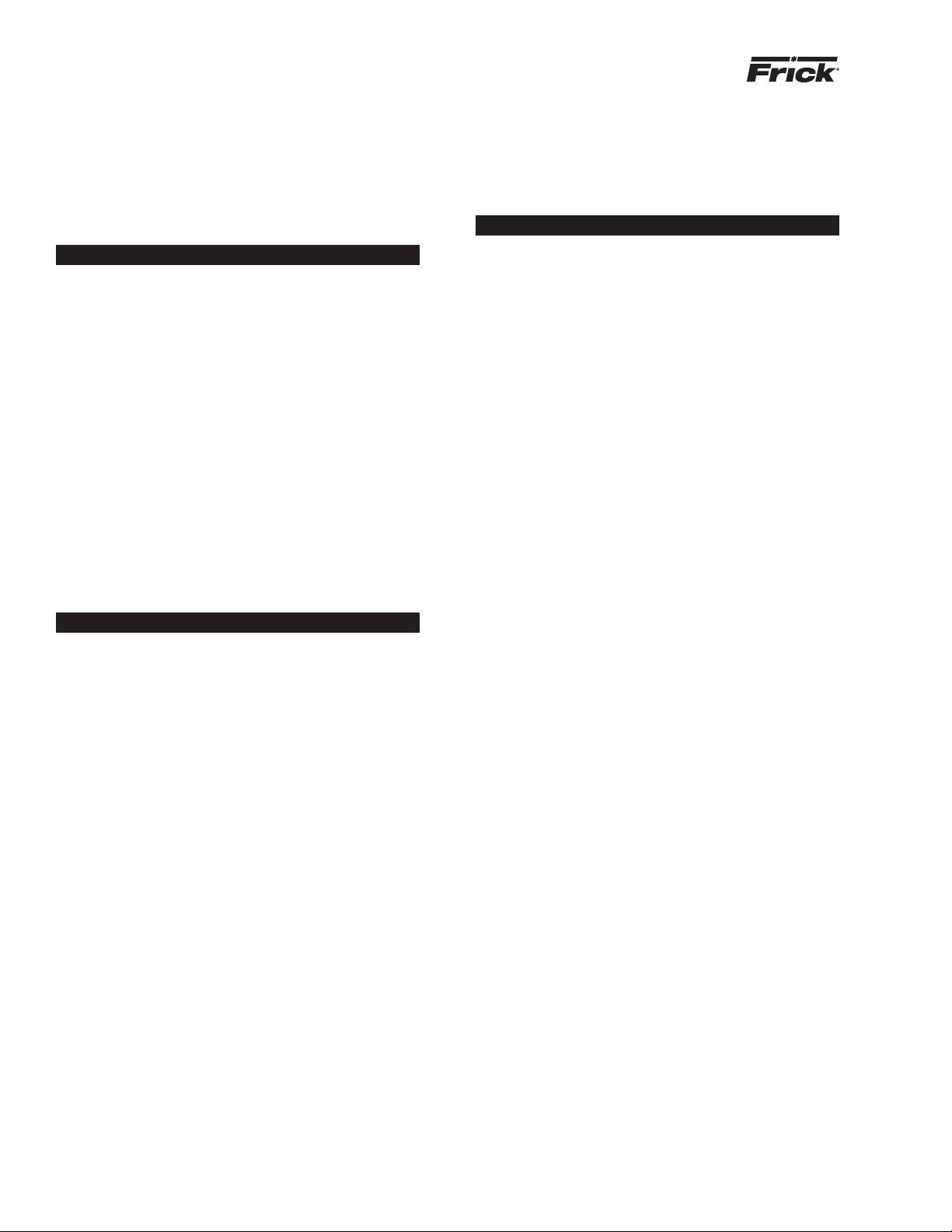

Liquid Injection Oil Cooling................................................ 9

Dual Dip Tube Method ....................................................... 9

Level Control Method......................................................... 9

Water-Cooled Oil Cooling................................................ 10

Thermosyphon Oil Cooling.............................................. 10

Economizer - High Stage................................................. 12

Electrical.......................................................................... 13

Motor Starter Package..................................................... 13

Current Transformers (CT) Ratios ................................... 14

Minimum Burden Ratings ................................................ 14

Battery Backup ................................................................ 14

OPERATION

General Information......................................................... 15

Microprocessor Control Panel ......................................... 15

Keys and Key Functions .................................................. 16

To Change The Adjustable Setpoints .............................. 18

How To Determine Adjustable Setpoints ......................... 18

Temperature-Pressure Control Program ......................... 22

Lead-Lag (Option) ........................................................... 24

Communications Troubleshooting.................................... 24

How The Microprocessor Works - Summary ................... 25

Multiple Compressor Sequencing.................................... 26

Microprocessor Telecommunications............................... 27

Communications Protocol Specifications ........................ 27

RXB Compressor............................................................. 30

Compressor Lubrication System ..................................... 30

Full-Lube Oil System ....................................................... 30

Compressor Oil Separation System ................................ 30

Compressor Hydraulic System ....................................... 31

Compressor Oil Cooling Systems.................................... 32

Single-Port Liquid Injection.............................................. 32

Dual-Port Liquid Injection ................................................ 33

Liquid Injection Adjustment Procedure............................ 33

TABLE OF CONTENTS

Prestart Checklist ............................................................ 34

Initial Start-up Procedure................................................. 35

Normal Start-up Procedure ............................................. 35

Restarting Unit After Power Failure ................................. 35

MAINTENANCE

Normal Maintenance Operations..................................... 36

Compressor Shutdown and Start-up ............................... 36

General Instructions For Replacing

Compressor Unit Components..................................... 36

Suction Check Valve Bypass Valve.................................. 36

Oil Filter, Single ............................................................... 36

Oil Filter, Dual.................................................................. 37

Strainer, Oil Return.......................................................... 37

Strainer, Oil Pump (Optional)........................................... 37

Strainer, Liquid Injection .................................................. 37

Coalescer Filter Element ................................................. 38

Changing Oil.................................................................... 38

Recommended Maintenance Program............................ 38

Vibration Analysis ............................................................ 39

Oil Quality and Analysis................................................... 39

Motor Bearings ................................................................ 39

Operating Log.................................................................. 39

Maintenance Schedule.................................................... 40

Troubleshooting Guide..................................................... 41

Abnormal Operation Analysis and Correction ................. 41

Troubleshooting The Microprocessor............................... 42

EPROM Memory I/C Chip Replacement ......................... 45

SBC Board Replacement ................................................ 45

Microprocessor Display Replacement ............................. 45

Output Fuse Replacement............................................... 45

Pressure Transducers - Testing ....................................... 45

Pressure Transducer Conversion Data............................ 45

Pressure Transducers - Replacement ............................. 46

Volumizer Potentiometer - Replace/Adjust ...................... 47

Temperature/Pressure Adjustment .................................. 47

Bare Compressor Mounting............................................. 47

Troubleshooting The RXB PLUS:

Compressor ................................................................. 48

Oil Separator System................................................... 48

Hydraulic System ......................................................... 48

Full-Time Pump Systems............................................. 49

Liquid Injection Oil Cooling .......................................... 49

Thermal Expansion Valves .............................................. 50

Temperature Control Valve .............................................. 51

Wiring Diagrams .............................................................. 52

P and I Diagrams............................................................. 58

PROPER INSTALLATION OF ELECTRONIC

EQUIPMENT................................................................ 60

OPERATING LOG........................................................... 63