070.655-IOM (MAY 19)

Page 2

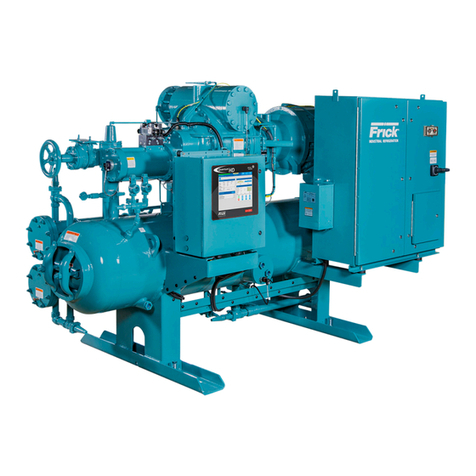

SBTP 408 ROTARY SCREW COMPRESSOR

INSTALLATION - OPERATION - MAINTENANCE

Contents

GENERAL INFORMATION

Preface ............................................................................. 3

Design limitations ............................................................. 3

Job inspection .................................................................. 3

Standard bare compressor ............................................... 3

Transit damage claims ...................................................... 3

Compressor identication ................................................ 3

Long term storage............................................................. 4

Preparing compressor for storage..................................... 4

Maintaining compressor.................................................... 5

Description........................................................................ 5

FRICK 408 mm compressor .......................................... 5

Compressor lubrication system .................................... 5

Oil pump ....................................................................... 5

Construction details...................................................... 6

INSTALLATION

Design limits ..................................................................... 7

Outline dimensions ........................................................... 7

Holding charge and storage .............................................12

Rigging and handling........................................................12

Foundation ......................................................................12

Customer connections .....................................................12

Compressor oil.................................................................13

Oil pump ..........................................................................13

Compressor rotation is clockwise when facing the end

of the compressor shaft...............................................13

Motor mounting (foot mounted only)...........................13

Compressor/motor coupling requirements...................13

Coupling alignment requirements ................................13

Oil heater(s) .....................................................................13

Oil lter(s) .......................................................................13

Oil cooling requirements................................................. 14

Dehydration / evacuation test ......................................... 14

Electrical installation ....................................................... 14

Slide stop transmitter ................................................. 14

Capacity slide valve transmitter .................................. 14

Directional control valves ...........................................15

OPERATION

Operation and start-up instructions ................................16

Compressor hydraulic system .........................................16

Volumizer volume ratio control .......................................16

Low ambient operation ...................................................17

Initial start-up .................................................................17

Initial start-up procedure ............................................17

Normal start-up procedure .........................................17

MAINTENANCE

General information ........................................................18

Normal maintenance operations .....................................18

General maintenance ..................................................18

Changing oil ................................................................18

Recommended maintenance program ........................18

Vibration analysis.............................................................18

Oil quality and analysis ....................................................19

Operating log ..............................................................19

Troubleshooting guide .....................................................19

Abnormal operation analysis and

correction ...................................................................19

Capacity linear transmitter replacement -

slide valve .................................................................. 20

Volumizer transmitter replacement - slide stop.......... 20

Bare compressor replacement ....................................... 20

Shutdown due to

improper oil pressure ..................................................... 20

Troubleshooting the 408 mm compressor .......................21

Troubleshooting the hydraulic system ..............................21

Troubleshooting the oil pump and system .......................22

Vibration data sheet........................................................ 24

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation or practice which, if not avoided, will result in death or

serious injury.

SAFETY PRECAUTION DEFINITIONS

Indicates a potentially hazardous situation or practice which, if not avoided, will result in damage

to equipment and/or minor injury.

Indicates an operating procedure, practice, etc., or portion thereof which is essential to highlight.

WARNING

CAUTION

DANGER

NOTICE