070.650-IOM (JUL 19)

Page 6

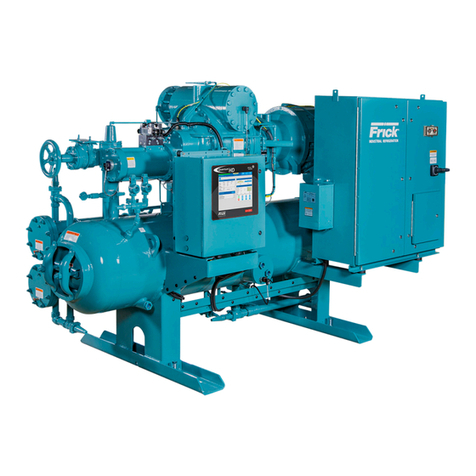

SGC/SGX ROTARY SCREW COMPRESSOR

INSTALLATION - OPERATION - MAINTENANCE

• Oil injected into the rotors to maintain good volumetric

andadiabaticefciencyevenatveryhighcompression

ratios.

• The shaft rotation is clockwise when facing the com-

pressor and is suitable for all types of drives.

Warning

Compressor rotation is clockwise when facing the

compressor drive shaft. Never operate the compressor

in reverse rotation as this results in bearing damage.

• SuctionanddischargeangesareANSIB16.1Class300

for all except the SGX 4013 model. SGX 4013 has Class

400suctionanddischargeanges.

• Integral suction strainers are provided for all models

except the SGX 35XX and 408 series. These models

must be ttedwithasuitablestrainer,#60meshx

.0065 in. diameter stainless steel wire or better, to pre-

vent damage to the compressor from particles entering

the suction area.

COMPRESSOR LUBRICATION SYSTEM

The lubrication system on SGC/SGX screw compressor units

performs several functions:

• Provides lubrication to bearings and seal.

• Provides a cushion between the rotors to minimize

noise and vibrations.

• Helps keep the compressor cool and prevents

overheating.

• Provides an oil supply to hydraulically actuate the slide

valve and slide stop.

• Provides oil pressure to the balance piston to help

increase bearing life. Some applications/operating

conditions require a regulated pressure to the balance

piston.

• Provides an oil seal between the rotors to prevent rotor

contact or gas bypassing.

• OnSGXmodels,providesoilsupplytothesqueezelm

dampers.

OIL PUMP

A demand oil pump is required for low differential pres-

sure applications. CoolWare™ provides a warning when

the oil differential pressure is too low. Oil being supplied

to the compressor from the oil separator is at system

discharge pressure. Within the compressor, oil porting

to all parts of the compressor is vented back to a loca-

tion in the compressor’s body that is at a pressure lower

than compressor discharge pressure. All oil entering the

compressor is moved by the compressor rotors out the

compressor outlet and back to the system oil separator.

AllSGXcompressorsareequippedwithsqueezelm

dampers (SFD) in the rotor blocking diameters. Depending

on operating conditions and power consumption, a full

time and full lube oil pump is required to supply oil to the

compressor (SB-3 and SB-4 ports) at a pressure up to 40

psi to 50 psi above discharge pressure. Coolware provides

the exact calculation at the actual operating condition. If

the calculation information is not available, ensure the oil

pressure is a minimum of 40 psi above discharge pres-

sure.

On all SGH compressors, the oil pressure to the balance

piston must be controlled and regulated through the SB-2

compressor port. For booster and low pressure applica-

tions, SB-2 may not need to be connected. For higher

operating pressure a balance piston regulator (BPR) must

be installed and piped to the SB-2 connection.

Since there are several variants of the BPR, use Coolware

to select the best option. Correct BPR information and

pressure settings are required. Do not run the compressor

without his information.

Notice

Do not run the compressor without the correct balance

piston regulator information and pressure settings.

CONSTRUCTION DETAILS

Housing

Castings for SGC/SGX screw compressors through model

3524 are close grain, pressure tight, and grey cast iron to

ensure structural integrity and mechanical and thermal

stability under all operating conditions. Ductile iron hous-

ings are also available for special applications.

Standard casing material for SGX 4013-4021 compressor

models is ductile iron grade 60-40-18 per ASTM A395

and ASME SA395. Contact Johnson Controls – FRICK sales

for additional information.

Rotors

The rotors are made from the highest quality steel bar-

stock or forgings to the exacting tolerances of FRICK de-

signedhigh-efciencyrotorproles.Thefour-lobedmale

rotor (5 lobes on 408) is connects directly to the driver.

The six-lobed female rotor (7 lobes on 408) is driven by

themaleonathinoillm.

Bearings

Antifriction bearings with L

10

rated life in excess of

50,000 hours at design conditions (using the FRICK Su-

perlter™) are used for reduced frictional horsepower and

superior rotor positioning. This results in reduced power

consumption, particularly at higher pressure ratios. Cy-

lindrical roller bearings are provided to handle the radial

loads and the thrust loads are absorbed by four point

contact or angular contact bearings. In addition, thrust

balance pistons are provided to reduce the thrust load

and improve bearing life.

Shaft seal

The compressor shaft seal is a single-face type with a

spring-loaded carbon stationary surface riding against a

cast iron rotating seat. The seal is capable of withstanding

static pressure up to 600 psig. During operation it vents to

low pressure to provide extended life.

The 408 compressors utilize silicon-silicon carbide seal

face material.