ENG

RUS

Table of Contents

Содержание

1. Foreword..........................................

2. Technical description.....................

2.1 General............................................

2.2 Climate classification.....................

2.3 Technical specifications................

2.4 Physical dimensions......................

2.5 Maximum weight per shelf.............

3. Safety Requirements.......................

4. Installation & operation..................

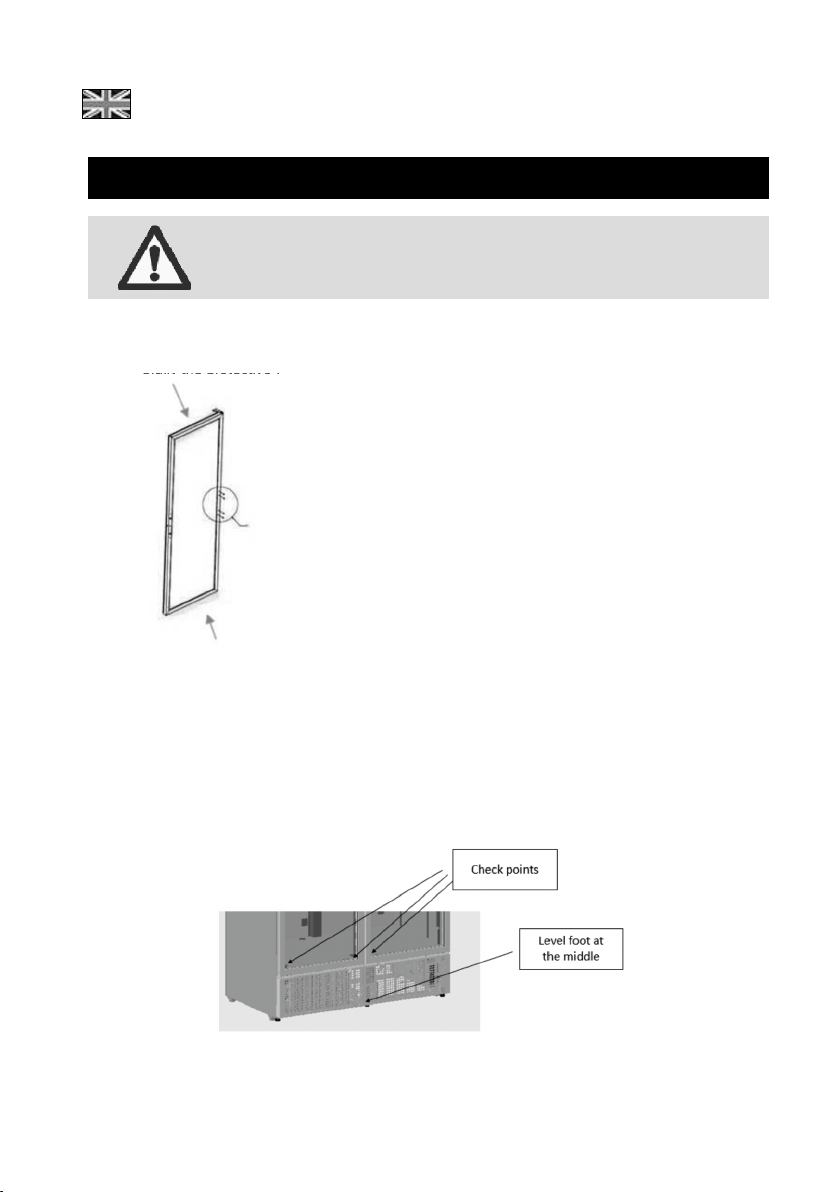

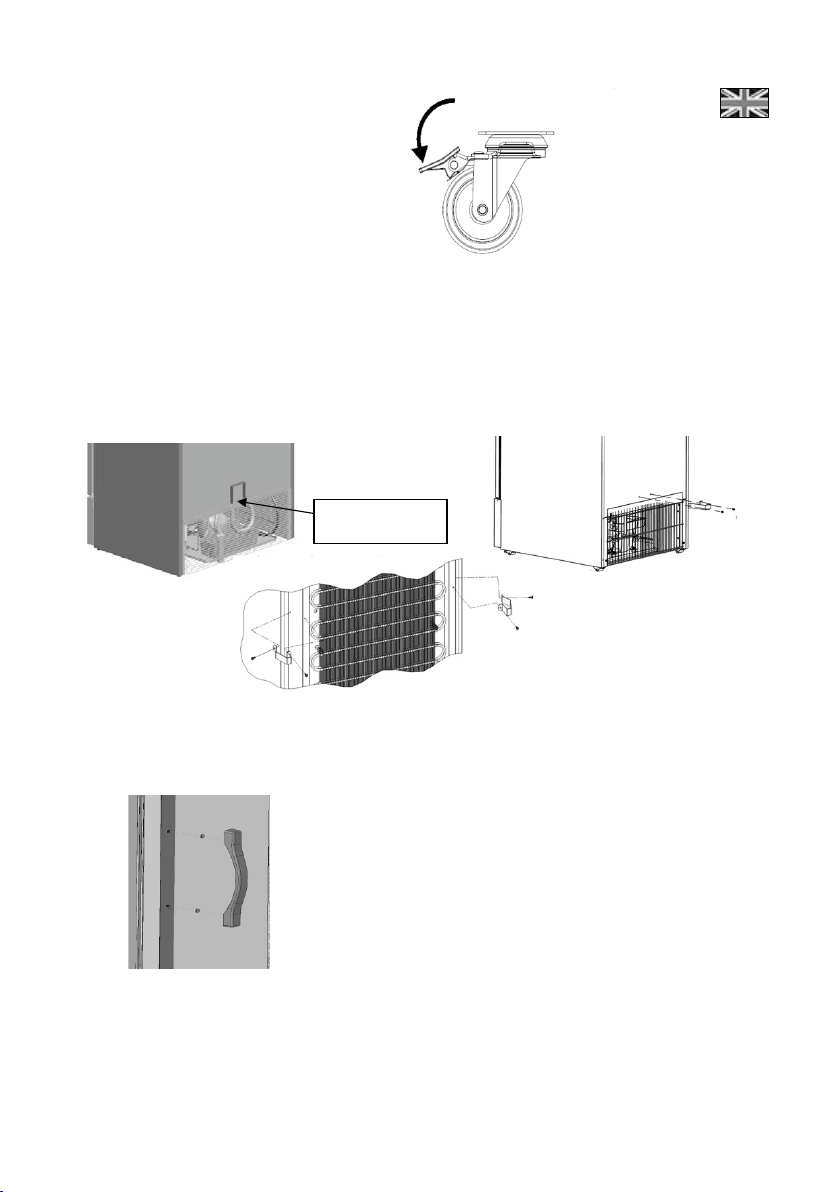

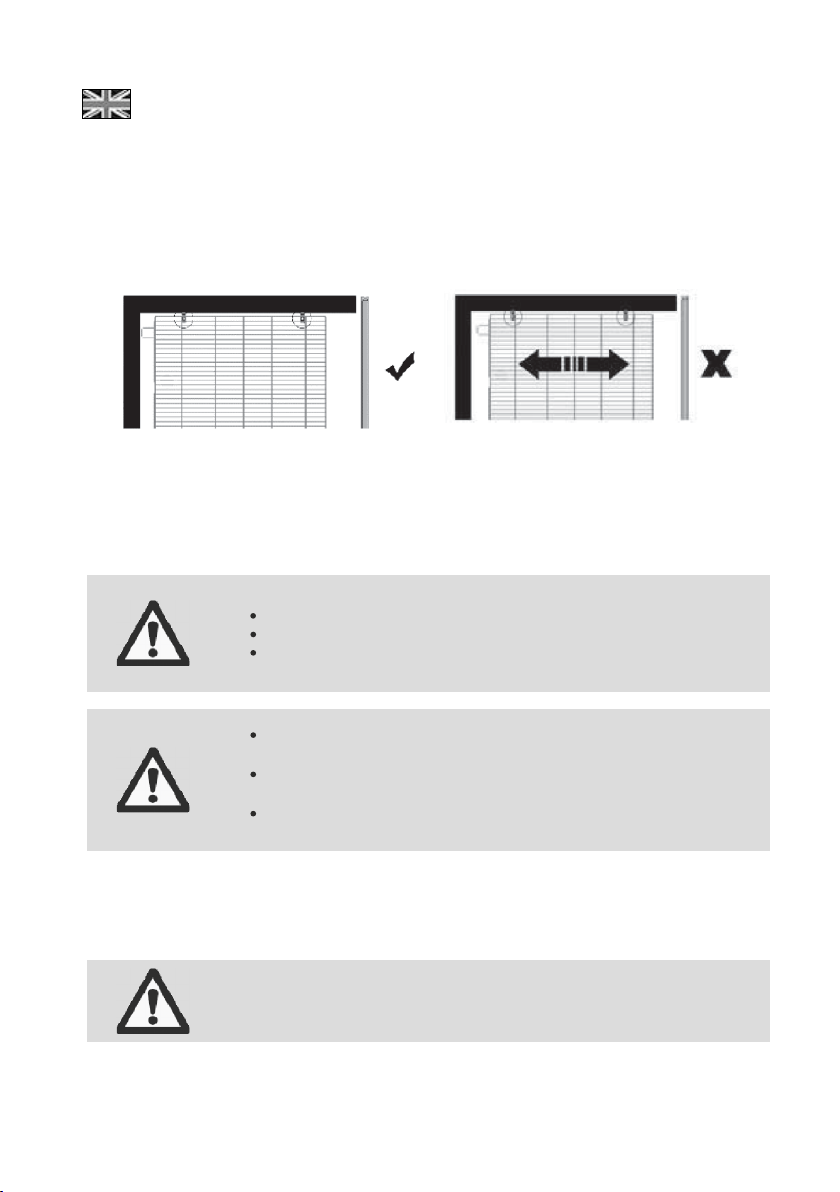

4.1 Installation instructions.................

4.2 Adjusting the shelf (not applicable

to units with plastic inner liner)...

4.3 Connection to the mains supply..

4.4 Operation instructions..................

5. Electronic controllers (optional) ...

6. Door blocking system...................

6.1 Application with hinged

door ICMs.......................................

6.2 ................. Frameless door option

6.3 Application with sliding

door ICMs......................................

7. Locking system.............................

7.1 Instructions for using the

padlock provision.........................

7.2 Instructions for using the

eye-lock..........................................

8. RCCB.............................................

9. Care & cleaning .............................

10. Troubleshooting............................

11. First aid...........................................

12. Disposal of the unit.......................

13. Recycling information...................

14. Warranty.........................................

APPENDIX A: Handling &

transportation guidelines.............

APPENDIX B: Preventive maintenance

guidelines......................................

APPENDIX C: Guidelines to prevent

corrosion of the cabinet...............

APPENDIX D: Link to instructions for

rehanging the door........................

1. Предисловие....................................

2. Техническое описание....................

2.1 Общая информация........................

2.2 Климатический класс.....................

2.3 Технические спецификации..........

2.4 Размеры............................................

2.5 Энергопотребление........................

2.6 Максимальная нагрузка на

экспозиционную полку...................

3. Требования безопасности.............

4. Установка и эксплуатация.............

4.1 Инструкции по установке..............

4.2 Установка экспозиционной полки

(не применяется в устройствах с

пластмассовой внутренней

облицовкой).....................................

4.3 Подключение к главной сети........

4.4 Инструкции по эксплуатации........

5. Электронные регуляторы.............

6. Система блокирования дверей....

6.1 Холодильные витрины с

откидной дверью............................

6.2 Безрамочные двери

(опционально).................................

6.3 Холодильные витрины с

раздвижной дверью.......................

7. Запорная система...........................

7.1 Инструкция по использованию

навесного замка..............................

7.2 Инструкция по использованию

встроенного замка..........................

8. Устройство защитного

отключения (УЗО)*..........................

9. Уход и чистка...................................

10. Устранение неполадок...................

11. Первая помощь................................

12. Утилизация устройств....................

13. Информация по утилизации

14. Гарантийные условия....................

ПРИЛОЖЕНИЕ I: Правила обращения

и транспортирования.....................

ПРИЛОЖЕНИЕ II: Правила

профилактического

обслуживания..................................

ПРИЛОЖЕНИЕ III: Правила

предотвращения коррозии в

камере...............................................

ПРИЛОЖЕНИЕ IV: Ссылка на

инструкцию по перенавесу...........

5

5

5

5

5

5

6

7

8

8

10

10

10

11

11

11

12

12

13

13

13

14

15

16

18

18

19

20

20

20

21

22

23

23

25

28

29

30

30

31

31

32

32

31

33

36

38

40

23

23

23

23

24

26

26

26

29

30

35

38

38

40

40

41

42