Page 8

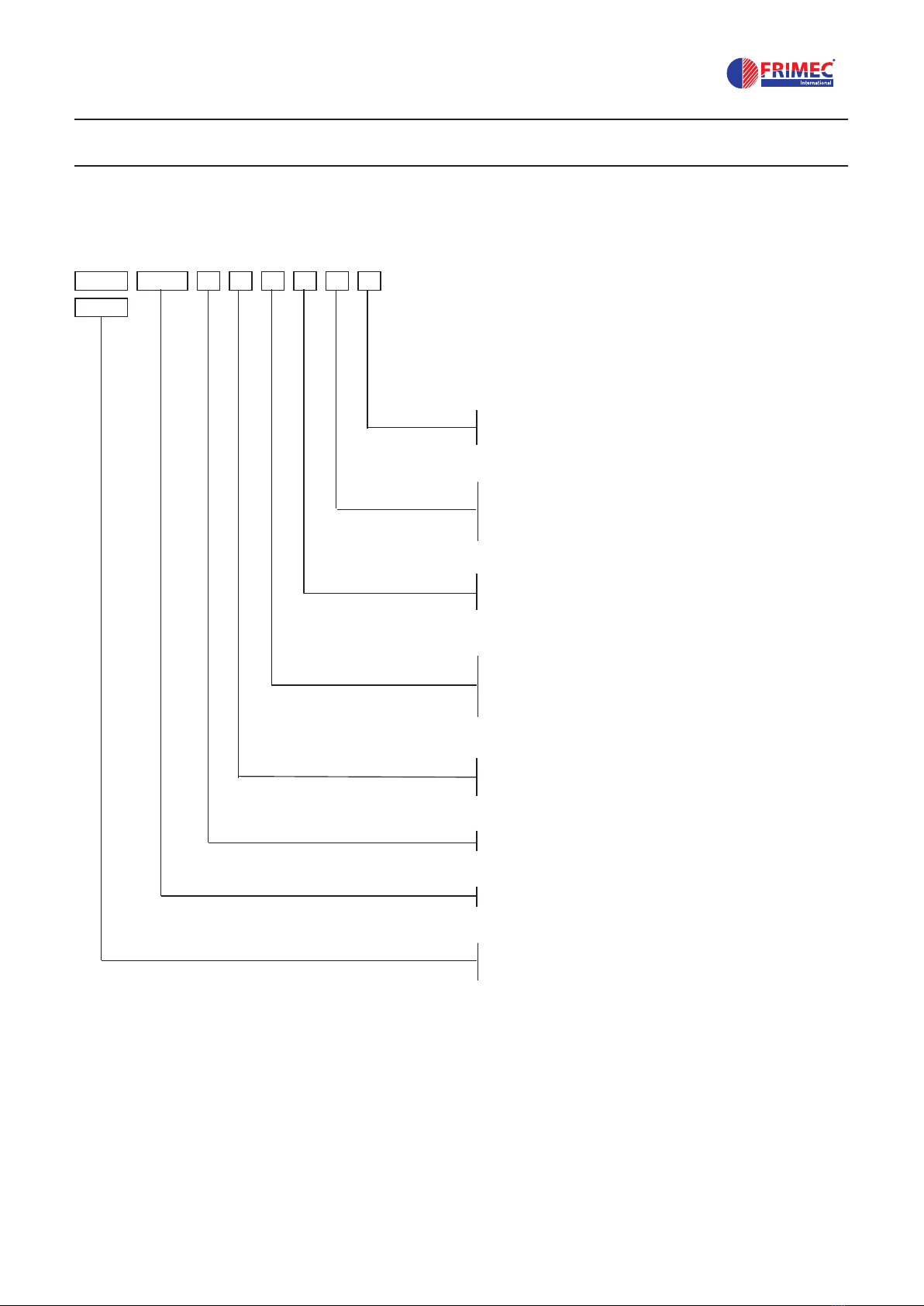

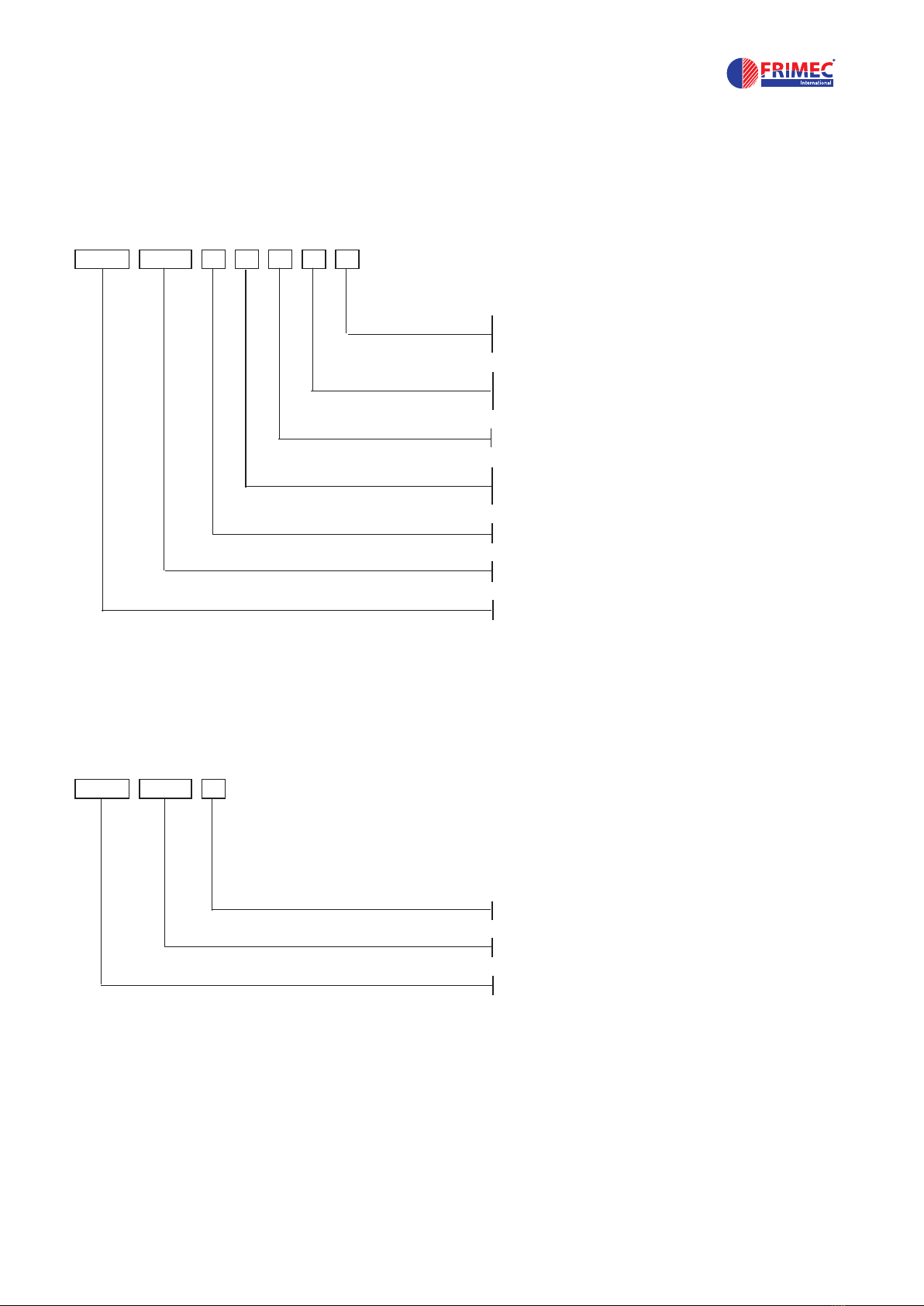

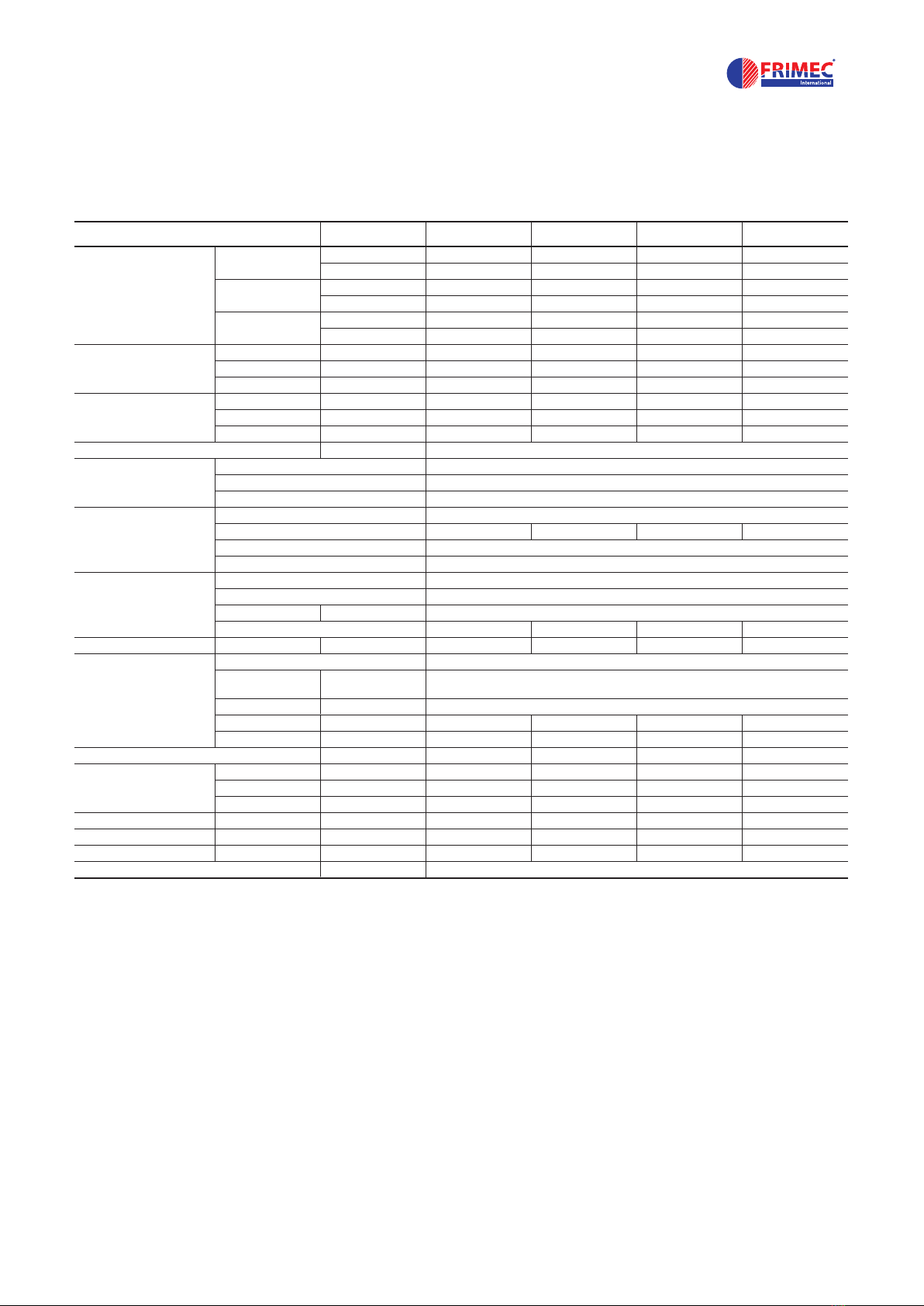

General Data - Ceiling Concealed FCU (3 rows coil)

50/60Hz

Model FCR 200E 300E 400E 500E 600E 800E 1000E 1200E 1400E

Air Flow

High CMH 350 520 680 850 1030 1380 1710 2040 2400

CFM 206 306 400 500 606 812 1006 1200 1412

Medium CMH 270 380 510 640 780 1030 1290 1540 1975

CFM 160 224 300 376 459 606 759 906 1160

Low CMH 190 280 340 450 560 740 890 1040 1255

CFM 112 165 200 265 329 435 524 612 738

Total Cooling Capacity

High W 2250 3180 4050 4920 5830 8115 9300 11800 13000

Medium W 2025 2765 3480 4130 4895 6895 8185 10265 11700

Low W 1665 2290 2875 3245 4255 5760 6325 7905 7560

Sensible Cooling Capacity

High W 1450 2080 2920 3535 4320 5660 6695 7480 9360

Medium W 1275 1750 2455 2900 3675 4695 5760 6280 7950

Low W 960 1415 1960 2190 2980 3790 4285 4635 5710

External Static Pressure High Pa 60

Low 30

Filter

Type Washable Type

Material Nylon

Thickness 8mm

Fan

Type Centrifugal forward curved blades

Quantity 1 2 2 2 2 3 4 4 4

Material Galvanized Steel

Drive Direct-drive

Motor

Type Permanent split capacitor with thermal overload protection

Insulation Class Class B

Power Supply V / Ph / Hz 220~240/1/50~60

Quantity 1 1 1 1 1 2 2 2 2

Rated Power Input at ESP: 60 Pa (H) W 65 75 90 110 150 178 228 270 340

at ESP: 30 Pa (L) W 42 55 65 82 105 148 171 212 253

Cooling Coil

Type Seamless copper tubes mechanically bonded to aluminium hydrophilic fins and collars

Max. Working Pressure MPa 2.0

Pipe Connection DN20 (3/4") - Female Threaded

Water Flow Rate l/s 0.11 0.15 0.20 0.25 0.28 0.39 0.44 0.56 0.62

Water Pressure Drop kPa 10 25 18 21 30 30 39 28 49

Net Weight kg 13 17 17 18 20 27 31 34 39

Dimension

Length mm 705 805 895 995 1105 1435 1635 1765 1765

Width mm 470 470 470 470 470 470 470 490 490

Height mm 240 240 240 240 240 240 240 250 300

Sound Pressure Level at ESP: 60 Pa (H) dB (A) 42 44 47 47 50 52 54 54 56

at ESP: 30 Pa (L) dB (A) 39 41 43 44 46 47 49 51 52

Condensate Drain Size DN20 (3/4") - Male Threaded

Note:

1) Nominal cooling capacity is based on the following condition:

a) Water temperature: 7.0°C (inlet) / 12.0°C (outlet)

b) Air entering condition: 27.0°C DB / 19.5°C WB

2) Air volume is tested under entering air condition of 20.0°C DB and dry coil condition.

3) All the units airflow value stated is at high speed.

4) Sound pressure level is based on 11.5 dB(A) anechoic room background noise.

Engineering Specifications

mm(in)

mm(in)

5) The manufacturer reserves the rights to make changes to the above specification without prior notice.