3

Table of contents

1 Introduction .......................................................... 5

1.1 Foreword.................................................................. 5

1.2 Manufacturer.......................................................... 5

1.3 Scope of delivery................................................... 5

1.4 Documentation ..................................................... 5

1.5 About this operator's manual........................... 6

1.6 Typographical conventions .............................. 6

2 Safety........................................................................ 7

2.1 Intended use........................................................... 7

2.2 Foreseeable misuse.............................................. 7

2.3 Machine-specific safety instructions.............. 7

2.4 Signs attached to mixer...................................... 9

2.5 Noise emissions ..................................................... 10

2.6 Disposal .................................................................... 11

3 Design and function.......................................... 12

3.1 Principle of design................................................ 12

3.2 Hopper...................................................................... 12

3.3 Pipes........................................................................... 13

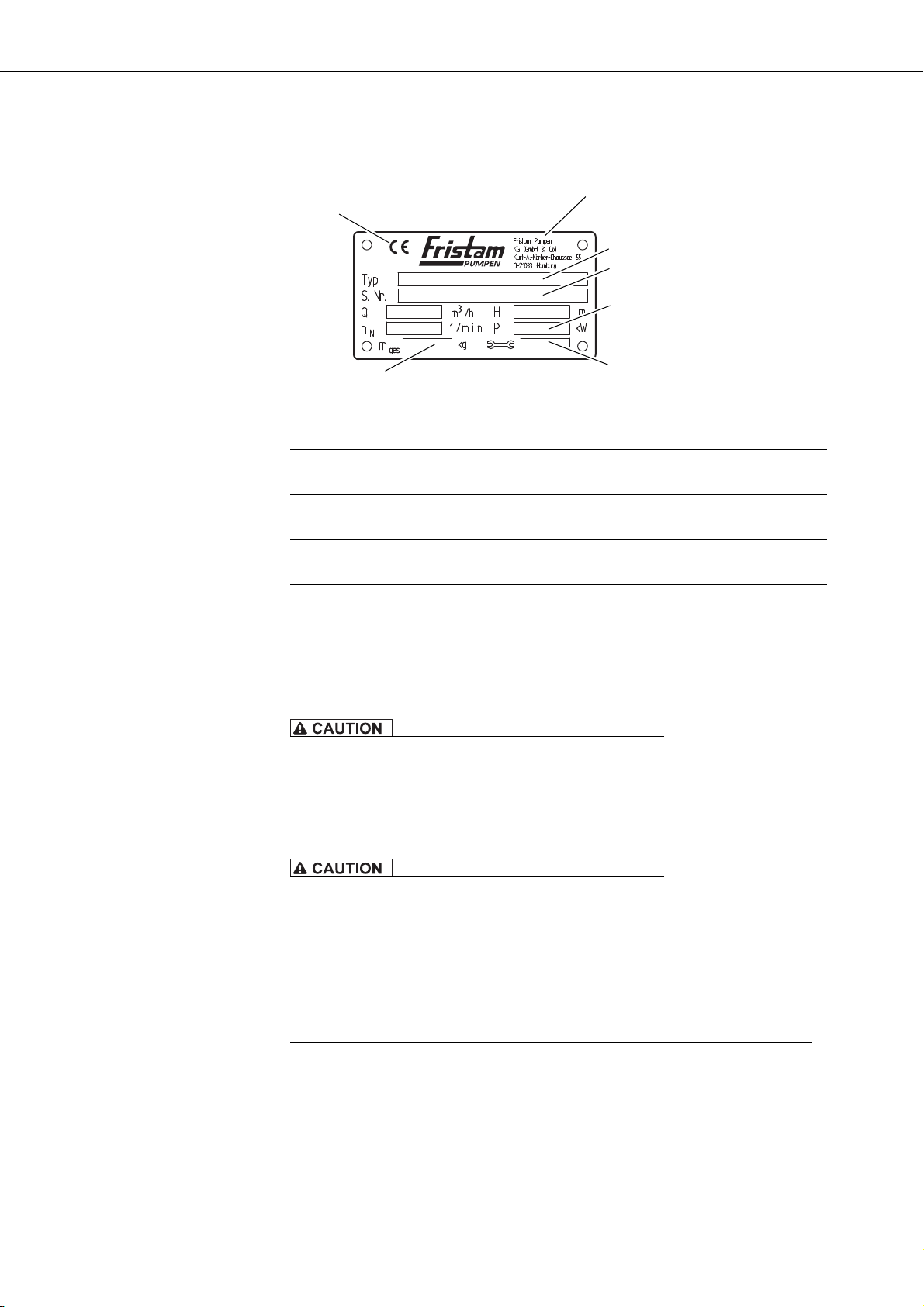

3.4 Pumps ....................................................................... 14

3.5 Control cabinet (optional) ................................. 14

3.6 Vibration motor (optional)................................. 16

3.7 Screen (optional)................................................... 16

3.8 Protective grille (optional)................................. 16

3.9 Mixer sizes and standard equipment ............ 17

3.10 Hydraulic diagram ................................................ 18

3.11 Function ................................................................... 19

4 Transport................................................................ 19

4.1 Safety instructions ................................................ 19

4.2 Transporting powder mixer on industrial

truck........................................................................... 20

4.3 Transport by crane................................................ 20

5 Storage .................................................................... 21

5.1 Safety instructions ................................................ 21

5.2 Storage conditions ............................................... 21

5.3 Mothballing powder mixer ............................... 21

5.4 Recommissioning ................................................. 21

6 Installation ............................................................. 22

6.1 Safety instructions................................................. 22

6.2 Location of installation........................................ 22

6.3 Measures to reduce noise and vibration....... 22

6.4 Fixture of powder mixer...................................... 23

6.5 Installing and connecting pipes....................... 23

6.6 Connections............................................................. 24

6.7 Hydraulic connection........................................... 24

6.8 Connection of power supply............................. 25

6.9 Checking direction of rotation of pumps ..... 25

6.10 Cleaning.................................................................... 26

7 Operation................................................................ 28

7.1 Switching powder mixer on (mixer with

control cabinet)...................................................... 28

7.2 Starting powder mixer......................................... 28

7.3 Monitoring mixing operation ........................... 29

7.4 Switching powder mixer off .............................. 30

8 Faults......................................................................... 30

8.1 Safety instructions................................................. 30

9 Maintenance.......................................................... 31

9.1 Safety instructions................................................. 31

9.2 Spare parts ............................................................... 31

10 Appendix................................................................. 32

10.1 Technical data......................................................... 32

10.2 Power data ............................................................... 33

10.3 Lubricants................................................................. 34

10.4 Troubleshooting table......................................... 34

10.5 Maintenance intervals ......................................... 37

10.6 EC Declaration of Conformity............................ 38