1 Technical data

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

Part 15 of the FCC rules. These limits are designed to

provide reasonable protecon against harmful interfer‐

ence when the equipment is operated in a commercial

environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and

used in accordance with the instrucon manual, may

cause harmful interference to radio communicaons.

Operaon of this equipment in a residenal area is

likely to cause harmful interference in which case the

user will be required to correct the interference at his

own expense.

The FCC ID is: WAFAMB2520T.

The evaluaon soware runs with WINDOWS XP / 7 / 8 © operang sys-

tems!

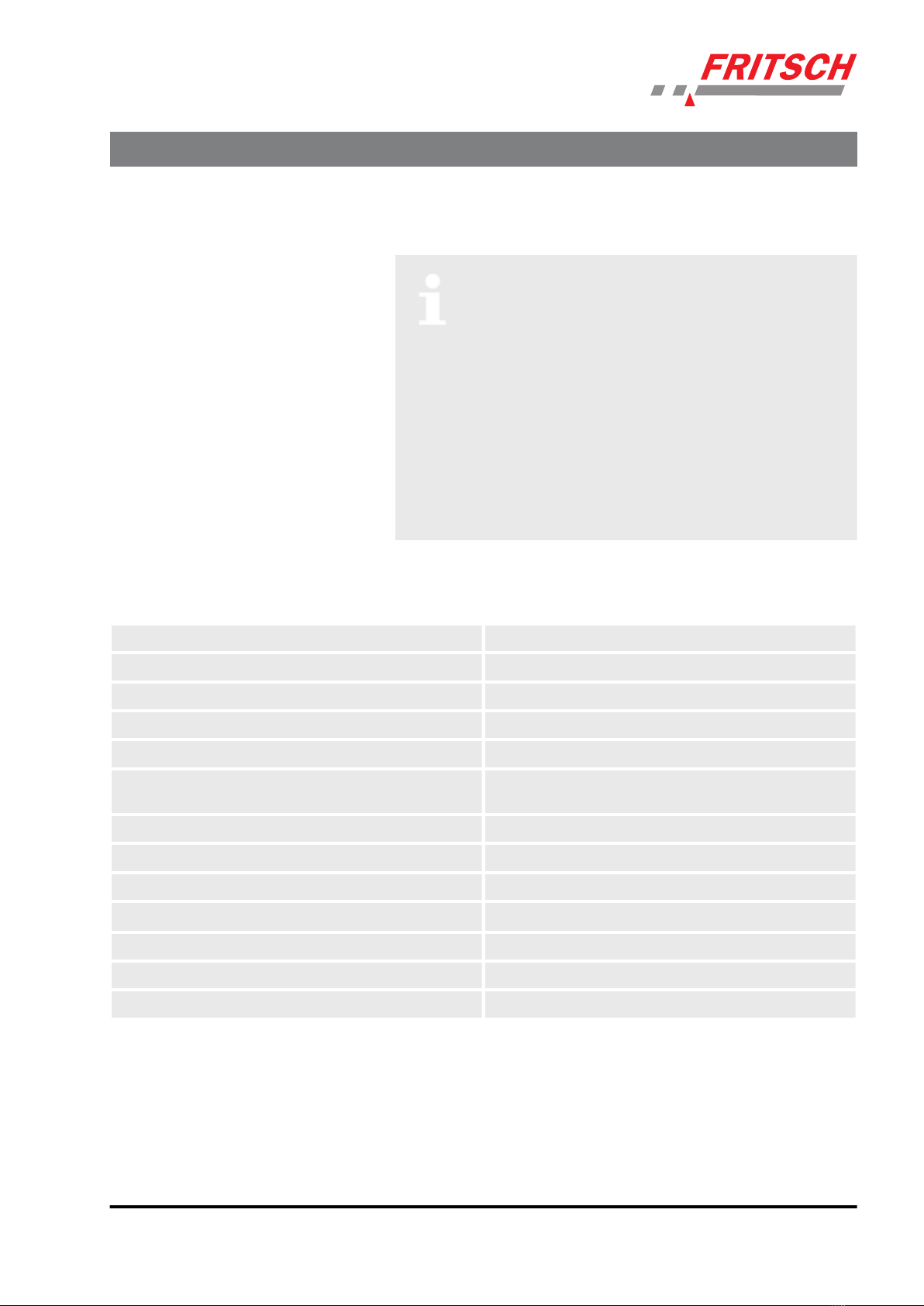

EASY GTM Pressure measure range 0 bar - approx. 30 bar

Allowable pressure in the bowl 0 - 20 bar

Measurement - dissoluon EASY GTM 1 mbar

Measure rate up to 4 values / s

Temperature range transmier unit -40°C - 110°C

Operang me with charged accu Depending to the operang temperature approx. 1/2

year of connuous operaon!

Data - transfer USB or oponal receiver USB-Sck

Radio - transfer 2,4 Ghz

Reach the radio - transfer typically 15m inside buildings

Baery AA 1x Energizer ® Ulmate Lithium (81.0022.00)

Change pressure-measurement < +/- 0,5%

Temperature-dependence < +/- 1%

Pressure hysteresis < +/- 0,1%

Technical data

- 5 -