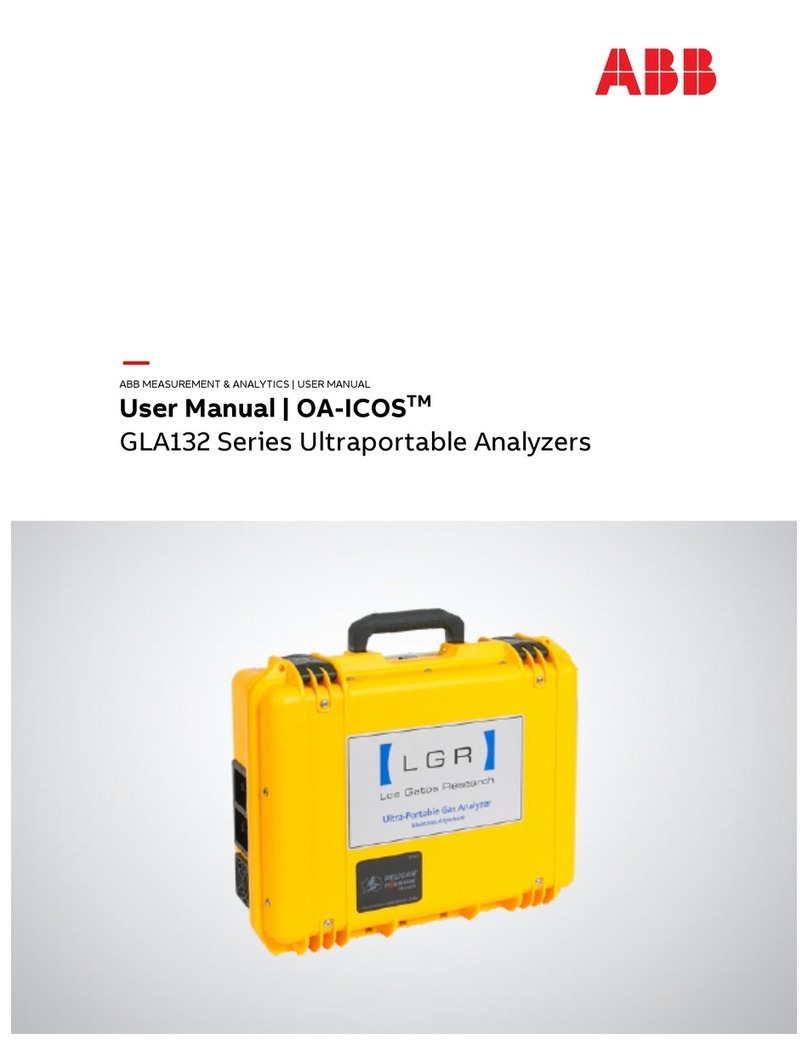

GLA531 Series LGR-ICOSTM Gas Analyzer

Operating Manual

3KXG165002R4201_2021_04

ABB PROPRIETARY INFORMATION 2

Table of Contents

Disclaimers .........................................................................................................................................................4

Patent......................................................................................................................................................................4

Copyright................................................................................................................................................................4

Trademark..............................................................................................................................................................4

Warranty.................................................................................................................................................................4

Customer Support..................................................................................................................................................5

1Introduction ...............................................................................................................................................6

2General Safety...........................................................................................................................................7

Symbols..................................................................................................................................................................7

Laser Product Class...............................................................................................................................................8

Electrical Safety and Fuse.....................................................................................................................................8

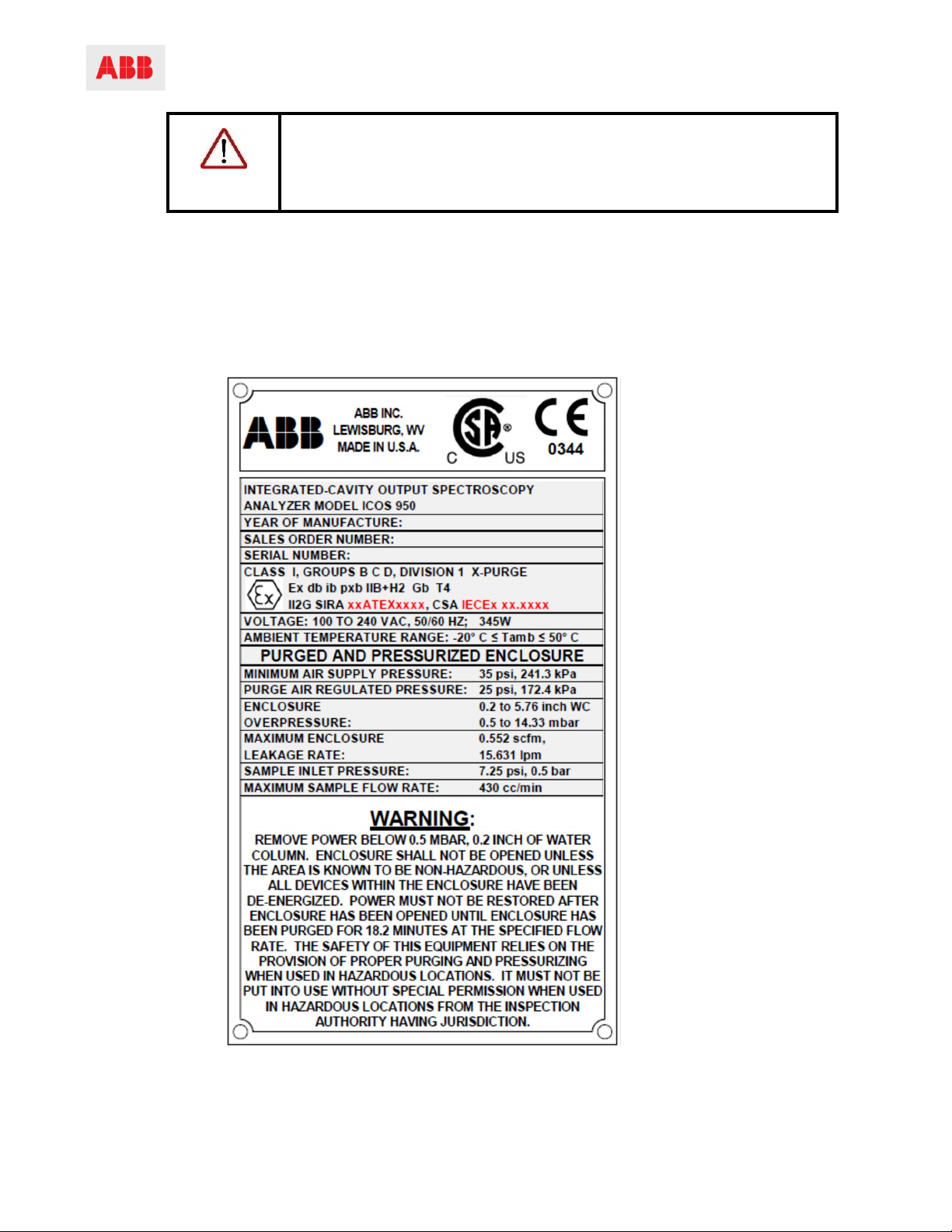

Certifications and Compliances.............................................................................................................................9

Operator Safety....................................................................................................................................................11

CDA Purge ......................................................................................................................................................11

N2Purge..........................................................................................................................................................12

Burn Hazards........................................................................................................................................................12

Laser Hazards......................................................................................................................................................13

Fire Safety Provisions..........................................................................................................................................14

WEEE Directive....................................................................................................................................................16

3Features and Theory of ICOS................................................................................................................17

Main Features.......................................................................................................................................................17

Theory of Operation.............................................................................................................................................17

LGR’s OA-ICOS...................................................................................................................................................19

4User Interface Operation........................................................................................................................20

Control Bar............................................................................................................................................................20

Display..................................................................................................................................................................21

Numeric Display...................................................................................................................................................21

Spectrum Display.................................................................................................................................................22

Time-chart Display...............................................................................................................................................23

Alarm Status Display............................................................................................................................................24

Rate Button...........................................................................................................................................................25

File Button.............................................................................................................................................................25

File Transfer .........................................................................................................................................................26

Setup Button.........................................................................................................................................................27

Time/Files.............................................................................................................................................................28

Calibration.............................................................................................................................................................30

Laser Adjust..........................................................................................................................................................31

4–20 mA Range Adjustment................................................................................................................................32

Service Screen.....................................................................................................................................................33

Shutting Down the Analyzer................................................................................................................................34

5Communications – Data and Alarms ...................................................................................................35

Input/Output Interface Hardware.........................................................................................................................35

Ethernet................................................................................................................................................................36

Modbus/TCP.........................................................................................................................................................36

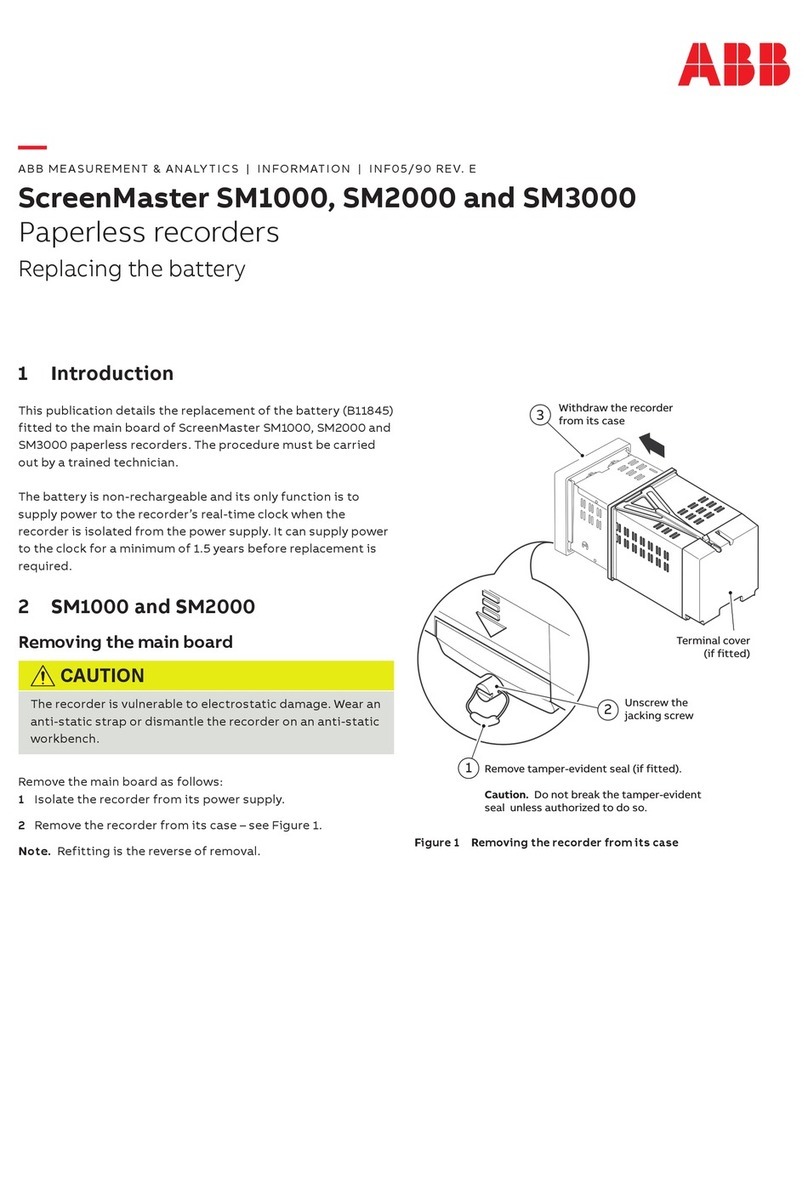

USB Drive – Local Data Access..........................................................................................................................38