Operation and Maintenance Manual PASS-1600ISO

889 Erie Ave, North Tonwanda NY, 14120

2.0

Installation and Operation

Upon powering the unit, the blower and UV lamps will be automatically activated. NO NOT power

the unit (plug the unit into 110VAC) until the unit air ducts have been connected and enclosure

panels are closed to eliminate potential of Ultraviolet Light exposure.

2.1

Preparation and Installation

NOTE: Read the entire manual prior to performing paragraph "2.1. Preparation."

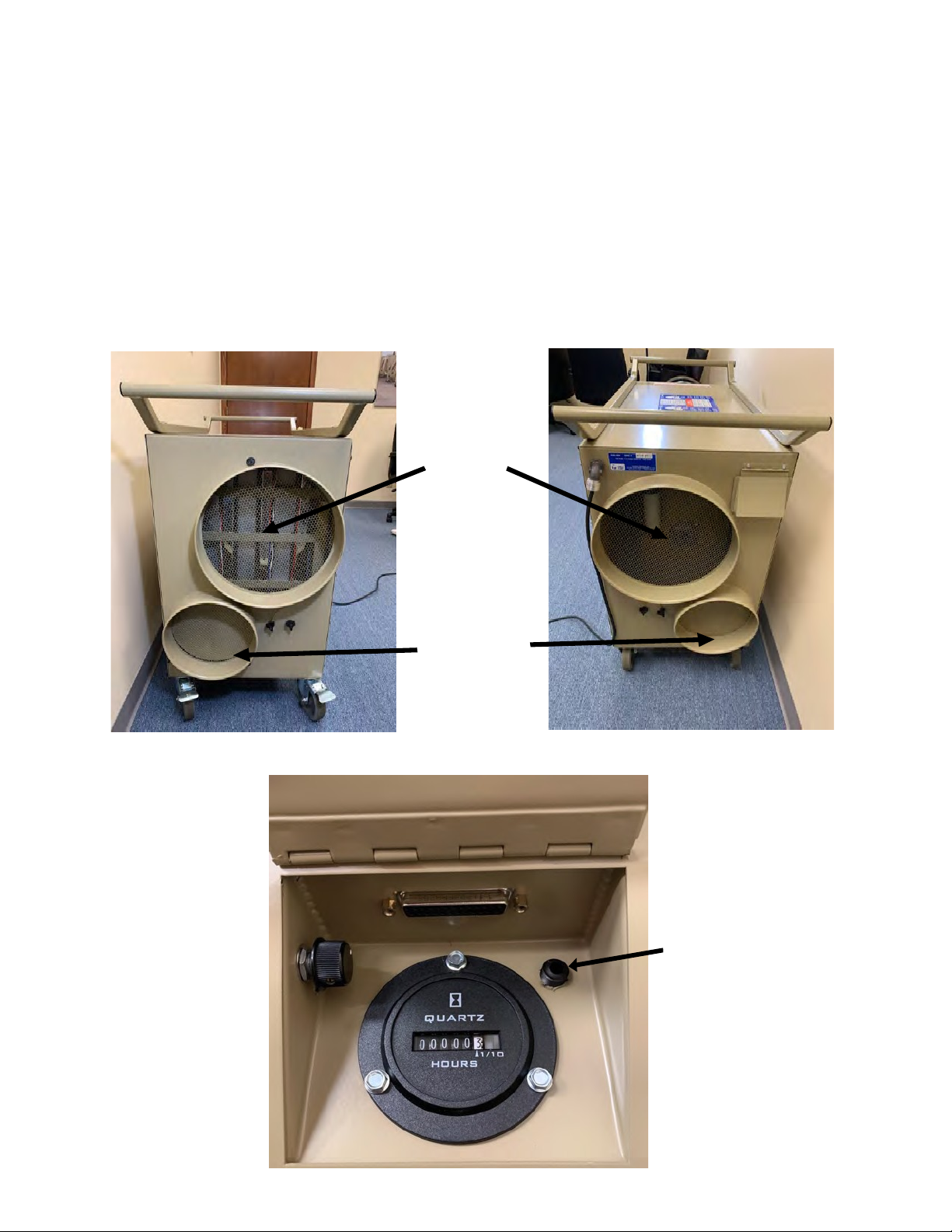

2.1.1 Move the unit to the desired location.

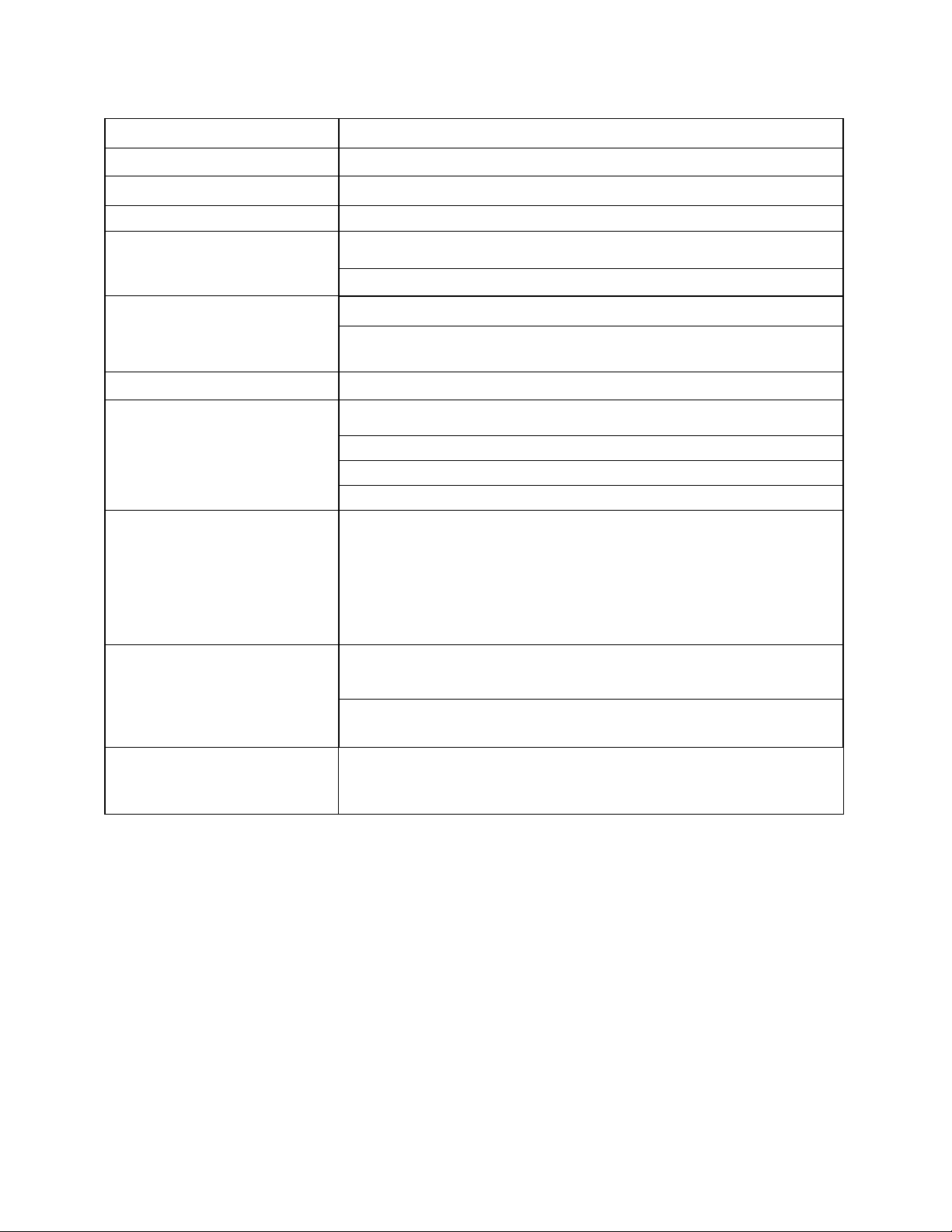

2.1.2 Lock the two locking wheels of the PASS unit.

2.1.3 Inspect the unit and ducts for any damage that could affect safety or function as well

inspect cleanliness. NOTE: The intake duct requires specific consideration as it may have been

exposed to unfiltered air and containments during previous use(s).

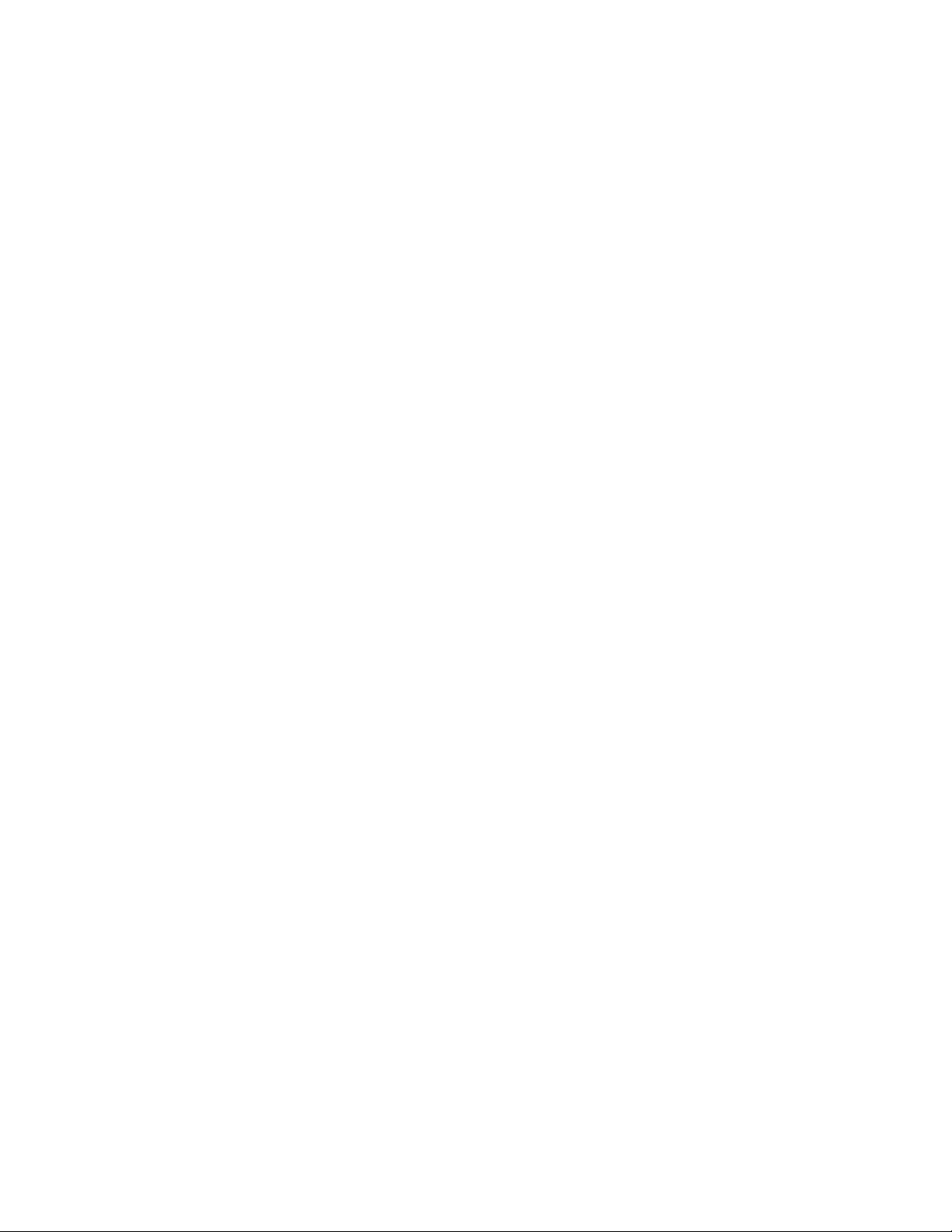

2.1.4 Unlock the filter section by rotating the nine (9) fasteners with

a coin or standard screwdriver 1/4 turn counterclockwise.

2.1.5 Open the compartment hinged panel.

2.1.6 Ensure that a fresh HEPA filter is in place and with the airflow

arrow pointing toward the outflow end of the unit.

2.1.7 Inspect to ensure that the UV lamps are in place and the

"front bank" electrical plug is connected (noted by orange circle)

2.1.8 Close the hinged filter panel, and lock the six (6) fasteners with a coin or standard

screwdriver one-quarter turn clockwise.

2.1.9 Install ductwork based on desired operation mode.

2.1.10 Connect controller to PASS unit (under hinged protective cover) and position

controller inside the shelter/facility.

2.2. Operation

2.2.1 Plug-in unit power cord. As soon as power is supplied the unit will begin a self-test and

upon completion will indicate filter and room pressures or errors if faults were sensed.

2.2.1 Adjust CFM (airflow) as desired using adjustable knob next to run-hour meter.