X SERIES HOUSINGS AND FILTERS

MANUFACTURER’S SUGGESTED RETAIL PRICES

Housings - X100

Model No. Description Price

X100B X100 BagVessel - BUNA Gasket

X100BA X100 BagVessel - API

X100C X100 Cartridge Vessel - BUNA Gasket

X100CA X100 CartridgeVessel - API

Housings include - Lid, Basket or Cartridge Plate and Gaskets (Leg-Foot assemblies not included)

X100 FILTER

VESSEL

OPTIONS & REPLACEMENT PARTS

➔

WARNINGS

The X100 vessel is only designed

to use lathe cut gaskets made of

self-energizing material such as

BUNA N orVITON. does not

recommend the use of gaskets or

O-rings that are made of non-self

energizing (i.e. non-elastomeric)

material such as rope type gaskets,

teflon, or graphite-impregnated

materials.

The X100 is talc-filled polypropy-

lene. Please refer to chemical

resistance guides for filter housing

compatibility with specific chemi-

cals at various temperatures. Only

use this housing with chemical vs.

temperature ratings of “+” or

“excellent”. FSI will not assume

responsibility for the use of this

housing with chemicals and/or at

temperatures and pressures that

are not compatible with or within

the safe operating range of this

filter housing. Please refer to

nameplate data on this housing

which gives maximum operating

temperature and pressure limits,

and which assumes the operation

of this housing is with chemically

compatible fluids. Consult the

Engineering Department

for pressure limits

at different operating and/or

ambient temperatures.

Part Description

Replacement Lid - No Gasket

X100 Plastic Basket

Cartridge Plate

(2) Plastic Leg and Foot Assembly

Carbon Steel Tripod Legs

304 Stainless Steel Tripod Legs

Lid Gasket (BUNA)

Lid Gasket (VITON)

Plate Gasket (BUNA)

Plate Gasket (VITON)

Patents Pending

Filter Bags - X01

Part No. Price

BPONG1X01

BPONG5X01

BPONG10X01

BPONG25X01

BPONG50X01

BPONG100X01

Part No. Price

BPMO100X01

BPMO150X01

BPMO200X01

BPMO300X01

BPMO600X01

BPMO800X01

Cartridges - X20

Part No. Price

CMMF [1-5] X20

CMMF [10-25] X20

CMMF [50-75-100] X20

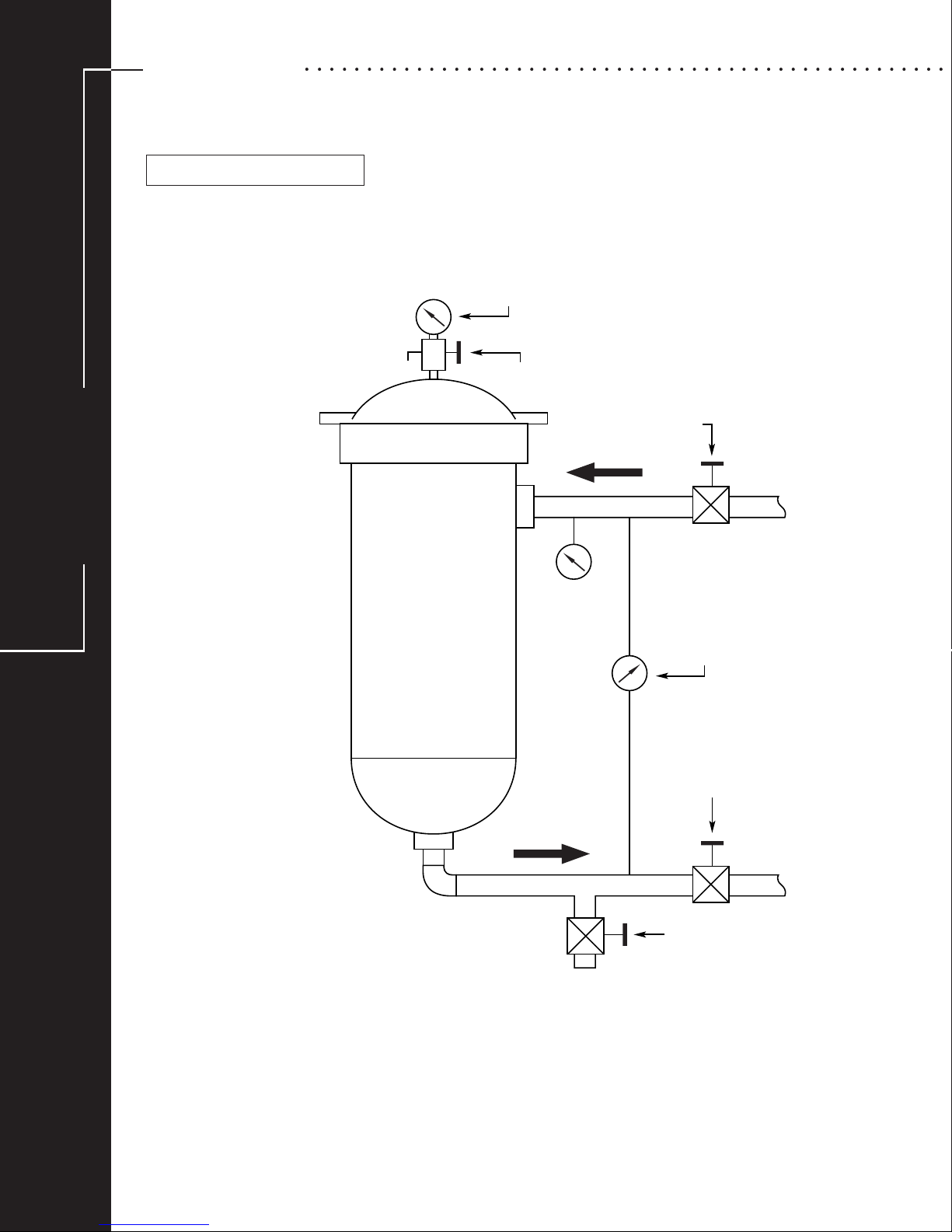

W A R N I N G

BEFORE USE

REMOVE RED CAP

PLUG

REPLACE WITH

COMPATIBLE

PLUG VALVE OR

GAUGE

W A R N I N G

WITH WATER

SERVICE

MAX PRESSURE

100 PSI

MAXTEMPERATURE

110¡F

W A R N I N G

BEFORE USE, CONSULT CHEMICAL COMPATIBILITY GUIDELINES.

This vessel is manufactured from talc filled polypropylene.The maximum

operating pressure is rated at 100 PSI with water where the

temperature does not exceed 110¡F. The operating pressure may vary

using other substances and temperatures.

Although this housing material has a wide range of chemical resistance,

there are several factors that affect or restrict the usage, i.e.,

temperature and concentration of solutions.Therefore, the user should

refer to published reference materials for chemical compatibility.

A partial list follows:

Compass Corrosion Guide-Section B.

Compass Chemical Resistance Guide for Elastomers.

Dow Chemical Resistance Guide.

DuPont Chemical Resistance and Fluid Compatibility.

Failure to comply with the chemical compatibility guidelines may result in

extensive vessel structural integrity failure.

SUCH FAILURE COULD RESULT IN SEVERE INJURY TO THE USER.

➔

X100 OPM 015 801

➔

Case Quantity - 50 Bags

Part No. Price

BPOMF0AX01

BPOMF1AX01

BPOMF2AX01

BPOMF10AX01

BPOMF25AX01

BPOMF90AX01

Case Quantity - 6 Cartridges