4. Rotate the propeller slowly about 10 to 20 times (more in winter) until fuel begins

to be drawn into the carburetor. Another way to prime the engine is to rotate the

prop clockwise from bottom dead center to top dead center (compression) and

then counterclockwise back to bottom dead center repeatedly.

5. Switch the ignition to ON.

6. Flip the propeller clockwise several times briskly.

7. After you hear some initial firing sounds, move the choke lever to the OPEN

position.

8. Set the throttle to high idle. Set the prop so that the magnets are 20° clockwise

from the magnet pick up when viewed from the front.

9. Flip the prop through compression rapidly. If this is done properly, the engine

will start between the first and the eighth flip of the prop. During our testing,

starting took an average of 4-6 flips.

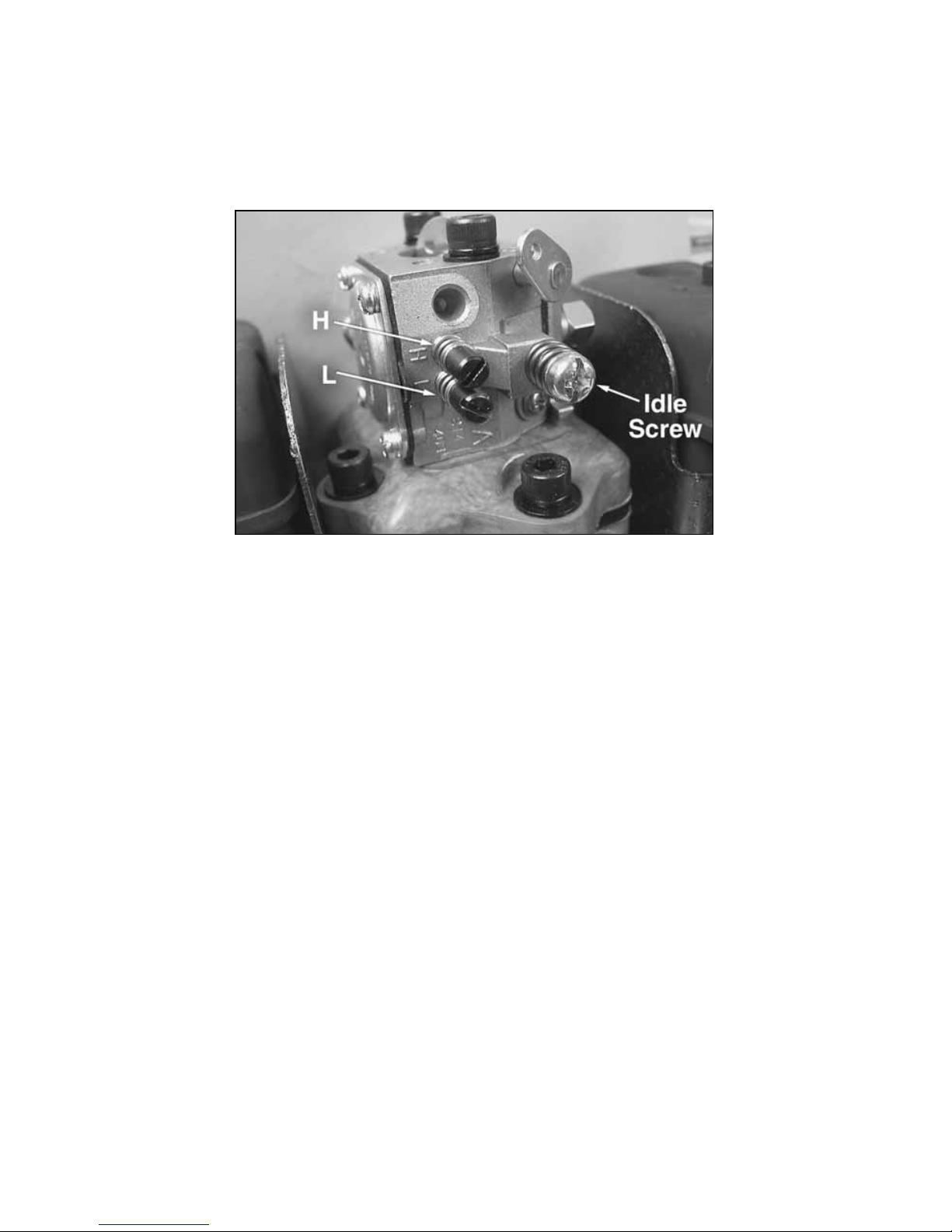

10. After starting, let the engine idle for two to three minutes. Open and close the

throttle slowly until the engine runs smoothly at idle and at full throttle.

Acceleration should also be smooth.

11. If your engine does not start, repeat the procedure.

B. Electric Starter Use:

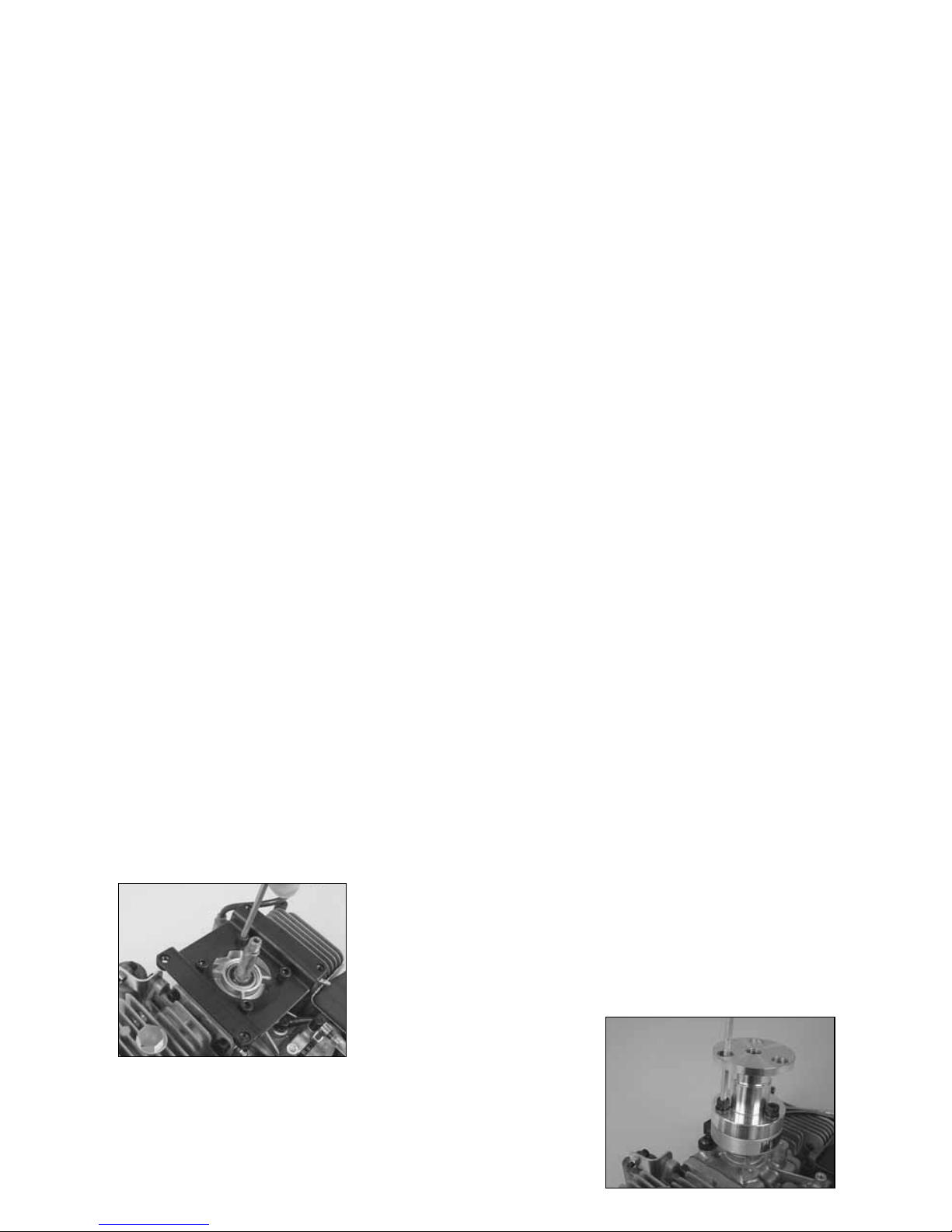

1. Make sure you use a good quality, lightweight aluminum spinner.

2. Have someone help you hold the airplane while you start it.

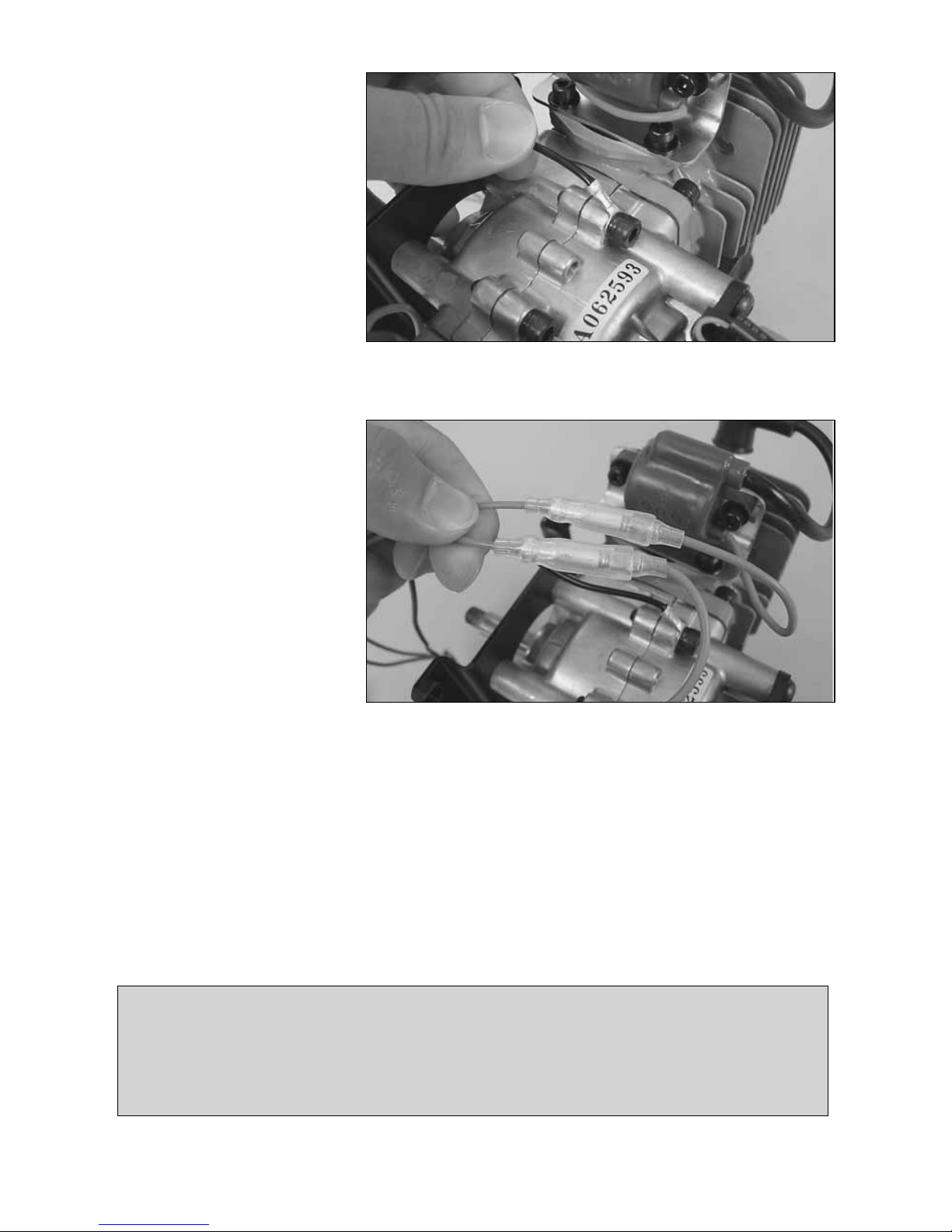

3. Make sure the ignition is OFF, close the choke plate on the carburetor and

open the throttle slightly from the idle position.

4. Use your electric starter to turn the engine over for several seconds.

5. Switch the ignition to ON and open the choke.

6. Set the throttle to high idle and use your electric starter to turn over the engine

until it starts.

7. After starting, let the engine idle for two to three minutes. Open and close the

throttle slowly until the engine runs smoothly at idle and at full throttle.

Acceleration should also be smooth.

8. If your engine does not start, repeat the procedure.

C. Spring Starting:

1. Have someone help you hold the airplane while you start it.

2. With the ignition OFF, close the choke plate on the carburetor and open the

throttle slightly from the idle position.

3. Rotate the propeller slowly about 10 to 20 times (more in winter) until fuel begins

to be drawn into the carburetor. Another way to prime the engine is to rotate the

prop clockwise from bottom dead center to top dead center (compression) and

then counterclockwise back to bottom dead center repeatedly.

4. Turn the ignition switch to the ON position.

5. Hold the propeller, turn it 360° clockwise (one full turn) and let it go (move

hand quickly away from the propeller arc).

6. After you hear some initial firing sounds, move the choke to the OPEN position.

7. Repeat Step 5 until your engine starts.

D. Onboard Electric Starter Use:

Follow the instructions supplied with the onboard electric starter.

7