817

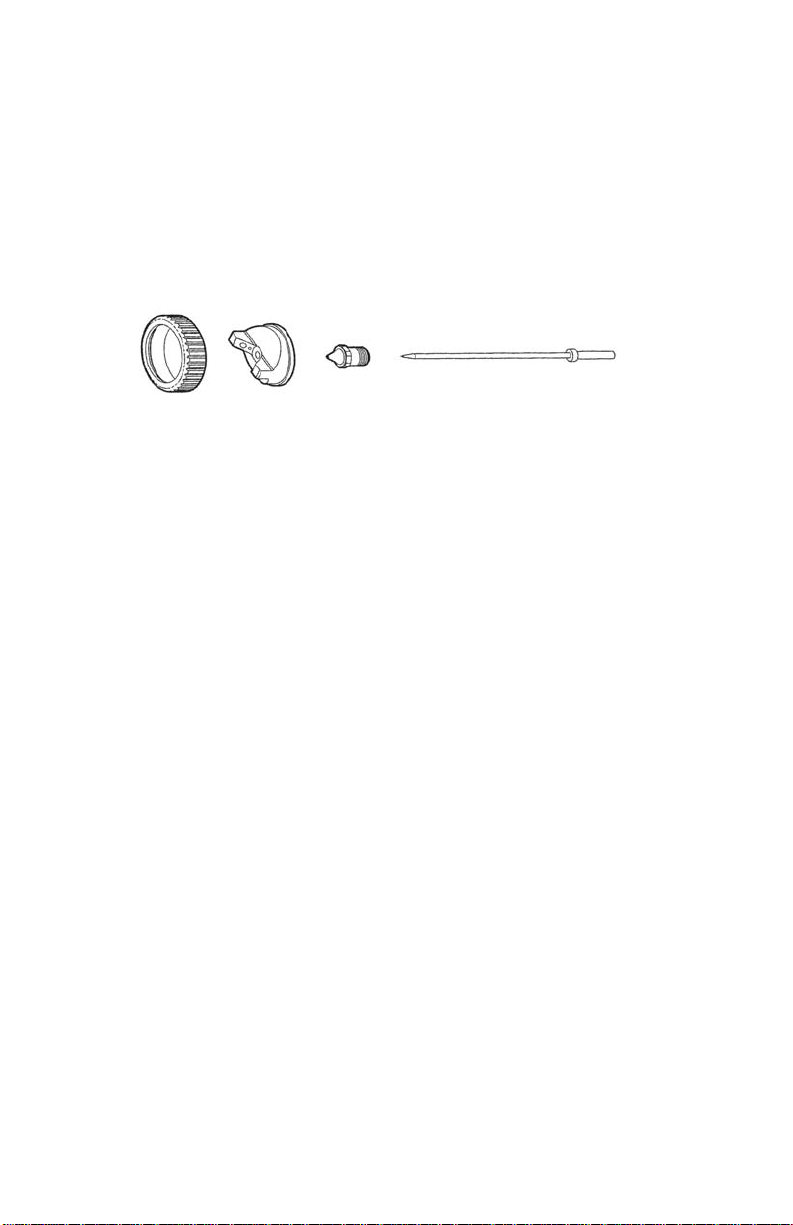

AIRCAPSET SELECTION

5 additional setups are available as accessories. Size No.3 is stan-

dard with all Fuji M-Sprayguns. No. 2, 3 or No. 4 can be used for any

type of fine-finishing application. The larger sizes such as No. 4 allow

formorefluid output. Thisisdesirablewhen sprayingfastdrying

lacquers. It allows you to spray wetter to obtain better leveling.

If you do not intend on spraying walls & ceilings then the only additional

setups you would ever need would be the No. 2 Fine and Medium No. 4.

No. 1 (Part 7020-1) .8mm (.031") SUPER-FINE OUTPUT

SHADING, STAINS.

No. 2 (Part 7020-2) 1mm (.039") FINE OUTPUT

SHADING, STAINS, WATERBORNECOATINGS.

No. 3 (Part 7020-3) 1.3mm (.051") FINE - MEDIUM OUTPUT- STANDARD

WATER-BASED LACQUERS,ACRYLICS, POLYURETHANE,STAINS.

No. 4 (Part 7020-4) 1.5mm (.059") MEDIUM OUTPUT

Similar to No. 3 but more coverage. Best forAUTOMOTIVE ENAMELS,

NITROCELLULOSE LACQUER and LATEX for a finer finish. Also ideal for

VARNISHES, PRIMERS, OIL-BASED PAINTS.

No. 5 (Part 7020-5) 1.8mm (.070") HIGH OUTPUT

Larger surfaces, thick layers, spotted effects. SEALERS, VARNISH,

POLYURETHANE, OILBASEDPAINTS,ENAMELS, EPOXY, PLASTIC,

ADHESIVES,FLOORPAVINGPAINTS,LATEX,ETC.

No. 6 (Part 7020-6) 2mm (.078") EXTRA HIGH OUTPUT

Very heavy flows, fast coverage. STONE FINISH PAINTS, TEXTURE

COATING,INDUSTRIALPRIMERS, MULTI-FLECKPAINTS, LATEX(on

walls, ceilings) ETC.

AIRCAP SET - Part 7020

TURBINECAREANDMAINTENANCE

FILTER(S)

It is important to clean or replace your filters regularly. Operating the

Turbineunit withclogged ordirty filterswill causethe Turbineto overheat

andresultin prematurefailure.The FujiHVLPTurbines haveeither1 or

2 Filters. To remove, simply pull the Filters out from Filter Enclosure.

Washinwarm soapy wateranddry before replacing.

All Fuji Filters are a friction fit. The Filter must fill the entire Filter Enclo-

sure.NOTE: Semi-PROandHobby-PRO Turbineshave twosquare fil-

ters, fine and coarse. The fine Filter is installed to the left side and the

coarsetotherightside (asseen lookingatthefrontof theTurbine where

the Hose is connected).

Cleaning your filters regularly is essential to maintaining your

Turbine. It is always a good idea to have a spare pair of filters on

hand.

TurbineFilterpartnumbers:

Semi-PROorHobby-PROTurbine(squareshapefilters) -Part #4009-2

All HVLP Turbines are designed for intermittent use. When taking a

breakbetween coatsorsteppingasidetorefillyour cup,it’sgoodpractice

to turn the Turbine off during this time. This allows the machine to cool

off.

When spraying, always ensure that the Turbine unit is at least 15 feet

away from spray project and in a well ventilated area. This will prevent

any overspray or debris being ingested into the Turbine. Failure to do

this may cause the filters to clog, resulting in damage to the internal

motor.

Itis agood ideato makeuse ofthe TurbineWireless Remote(Accessory

part # 3072). This device allows you to turn the Turbine unit on/off for

yourconveniencewithout havingtowalk back andforthto theTurbine.

Ifyou experiencea problemwith yourTurbine unit,please DONOT tryto

openandservicetheTurbineyourself.Contactusfortechnicalassistance.

Ifitisanissue of no power, checkyourpoweroutlet.Also, tryre-setting

the Breaker on the back of the turbine by pressing it once.