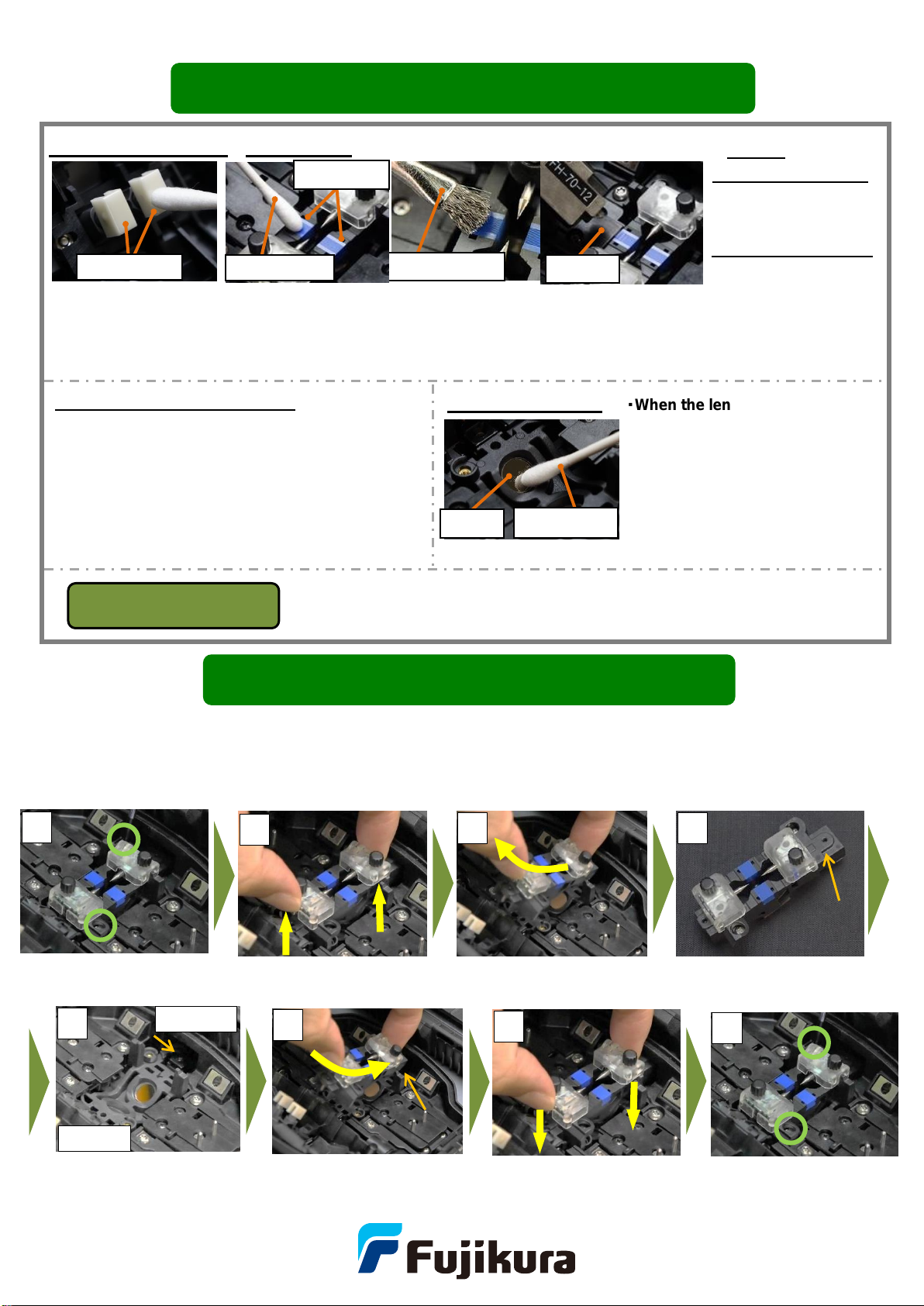

・The fiber end-face is placed on the

electrode centerline, or beyond it

・The cleave length (bare fiber part) is too

long

・Dust or dirt is on the objective lens

・Press RESET, and set the fiber end-face between the

electrode centerline and the V-groove edge.

・Confirm the set position of the stripped fiber end on the

fiber cleaver. Check the cleave length.

・Execute [Dust Check]. Clean the lens when dust or dirt

exists.

・Dust or dirt is on the fiber surface

・Dust or dirt is on the objective lens.

・[Cleaning Arc] time is too short or “OFF.”

・Completely prepare the fiber again (strip, clean and cleave).

・Execute the [Dust Check]. Clean the lens if dust or dirt

exists.

・Increase the [Cleaning Arc] time in small increments.

・The bare fiber is too far back and does

not reach the electrodes.

・The cleave length (bare fiber) is too short.

・Press RESET, re-position the fiber again with the end-face

closer to the electrodes.

・Confirm the set position of the stripped fiber end on the

fiber cleaver. Check the cleave length.

・Bad fiber end-face

・[Cleave Limit] is set too low

・Check the condition of the fiber cleaver. If the blade is

worn, rotate the blade to a new position. If dirty, clean

clamp pads, anvil, or blade.

・Load the default value from the splice mode database.

・Clean and check the condition of the fiber cleaver. If the

blade is worn, rotate the blade to a new position. If dirty,

clean clamp pads, anvil, or blade.

・Dust or dirt is on the fiber surface

・Bad fiber end-face

・Unstable arc discharge

・Completely prepare the fiber again (strip, clean and cleave).

・Check the condition of the fiber cleaver. If the blade is

worn, rotate the blade to a new position.

・Electrodes might be worn. Perform [Electrode Stabilization]

or replace electrodes.

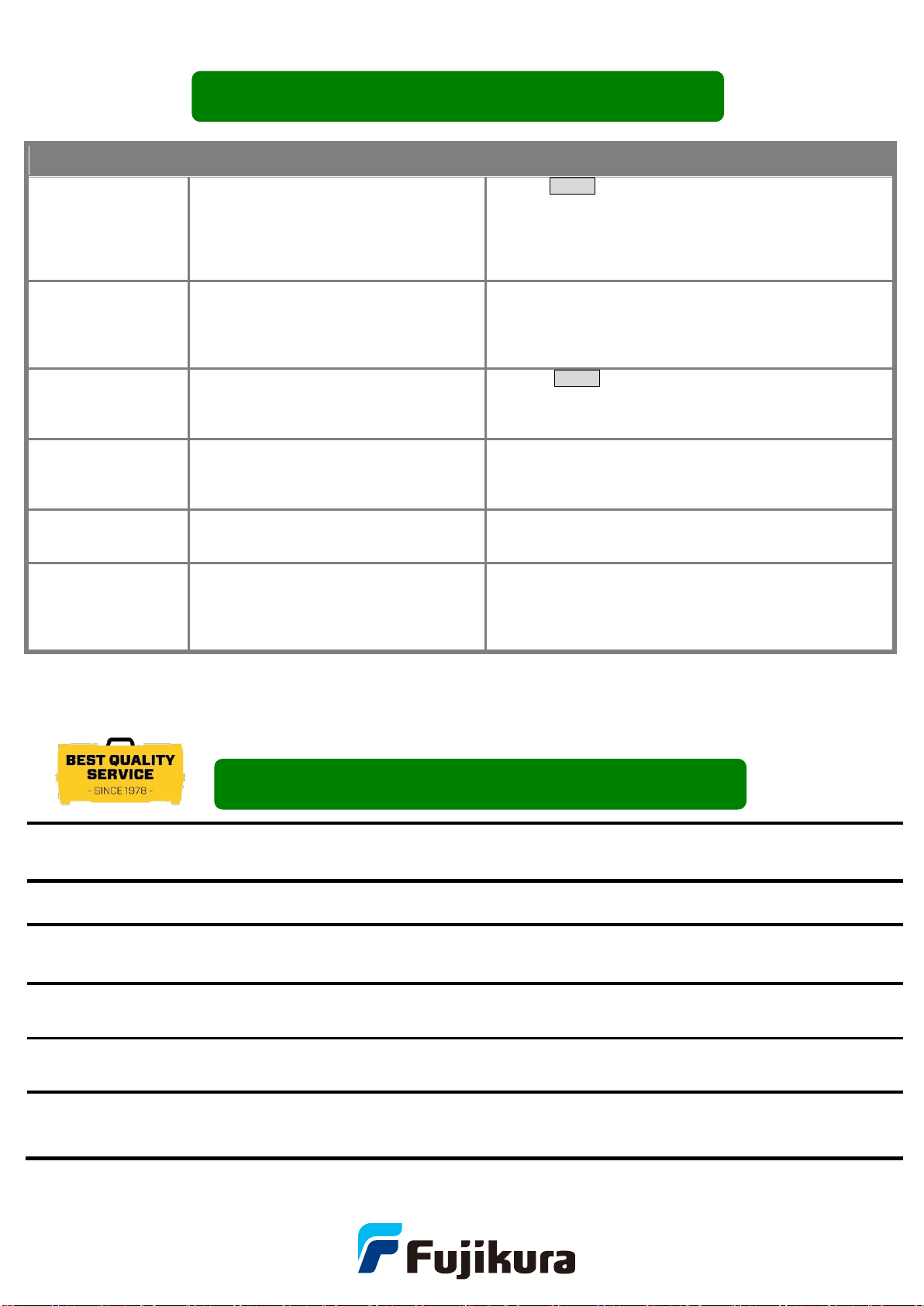

*This table only shows a few possible errors. Refer to the instruction manual for a more comprehensive list.

1-5-1, Kiba, Koto-ku, Tokyo 135-8512, Japan

General inquiries: +81-3-5606-1164

Service & support: +81-3-5606-1534

438A Alexandra Road,Block A Alexandra Technopark #08-03,Singapore 119967

General inquiries, service & support : +65-6-278-8955

https://www.fujikura.com.sg

C51 Barwell Business Park, Leatherhead Road, Chessington, Surrey, KT9 2NY, UK

General inquiries : +44-20-8240-2000

Service & support : +44-20-8240-2020

https://www.fujikura.co.uk

260, Parkway East, Duncan, SC29334, USA

General inquiries : +1-800-235-3423

Service & support : +1-800-866-3602

https://www.aflglobal.com

Fujikura (CHINA) Co., Ltd

7thFloor, Shanghai Hang Seng Bank Tower, 1000 Lujiazui Ring Road, Pudong New Area,

Shanghai 200120, CHINA

General inquiries, service & support : +86-21-6841-3636

http://www.fujikura.com.cn

Authorized Splicer Distributor

Solutions for Common Splicer Errors