!

!

7

•Wear ear protectors. Exposure to noise can cause hearing loss.

•Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal injury.

•Hold power tool by insulated gripping surfaces, when performing an operation

where the cutting accessory may contact hidden wiring or its own cord. Cutting

accessory contacting a “live” wire may make expose metal parts of the power tool “live”

an coul give the operator an electric shock.

WARNING! This appliance is not inten e for use by persons (inclu ing chil ren) with

re uce physical, sensory or mental capabilities, or lack of experience an knowle ge,

unless they have been given supervision or instruction concerning use of the appliance by

a person responsible for their safety.

Recommendations for the use of a residual current device with a rate resi ual current of

30mA or less.

• Always use an approve extension lea suitable for the power input of this tool. Before

use, inspect the extension lea for signs of amage, wear an ageing. Replace the

extension lea if amage or efective.

• When using an extension lea on a reel, always unwin the lea completely. Use of an

extension lea not suitable for the power input of the tool or which is amage or

efective may result in a risk of fire an electric shock.

• It is recommen e that the extension lea is a maximum of 25m in length. Do Not use

multiple extension lea s.

• Before rilling into walls, ceilings etc, ensure there are no conceale power cables or pipes

in the cavity.

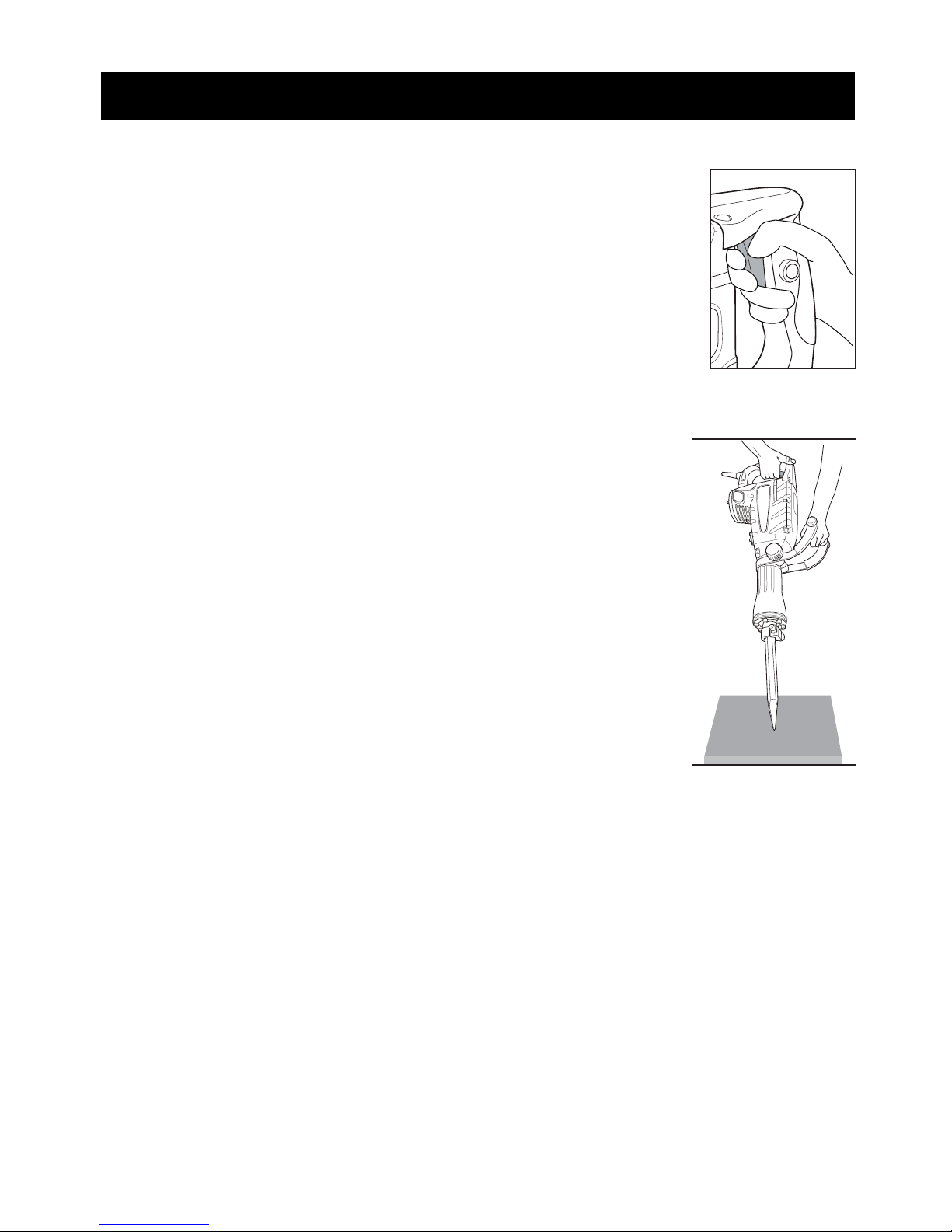

• Always use the si e han le, this gives you greater control if the accessory shoul

become jamme .

• Keep the cor clear of the accessory being use , o not wrap the cor aroun your arm

or wrist.

• Hol the tool by the insulate gripping surfaces when performing an operation where the

accessory may contact hi en wiring or its own cor .

• Use thick cushione gloves an limit the exposure time by taking frequent breaks.

• Vibration cause by the hammer action may be harmful to your han s an arms.

• When removing an accessory from the tool avoi contact with skin an use proper protective

gloves when grasping the bit or accessory. Accessories may be hot after prolonge use.

WARNING! Some ust create by power san ing, sawing, grin ing, rilling an

other construction activities contain chemicals known to cause cancer, birth efects

or other repro uctive harm.

Some examples of these chemicals are:

• Lea from lea -base paints;

• Crystalline silica from bricks, cement an other masonry pro ucts, an ;

• Arsenic an chromium from chemically-treate timber.

The risk from such exposures vary epen ing on how often you o this type of work. To

re uce your exposure to these chemicals; work in a well ventilate area, an work with

approve safety equipment, such as those ust masks that are specifically esigne to filter

out microscopic particles.

Always wear eye protection an a ust mask for usty applications an when rilling/chiselling

overhea . San ing particles can be absorbe by your eyes an inhale easily an may cause

health complications.

ADDITIONAL SAFETY RULES FOR DEMOLITION HAMMERS