IMPORTANT NOTES

WARNING: This suspension system will enhance the off-road

performance of your vehicle. It will handle differently, both on and

off-road, from a factory equipped passenger car or truck.

Extreme care must be used to prevent loss of control or vehicle

rollover during abrupt maneuvers. Failure to drive this vehicle

safely may result in serious injury or death to the driver and

passengers. ALWAYS WEAR your seat belts. Reduce your

speed, and AVOID sharp turns and other abrupt maneuvers.

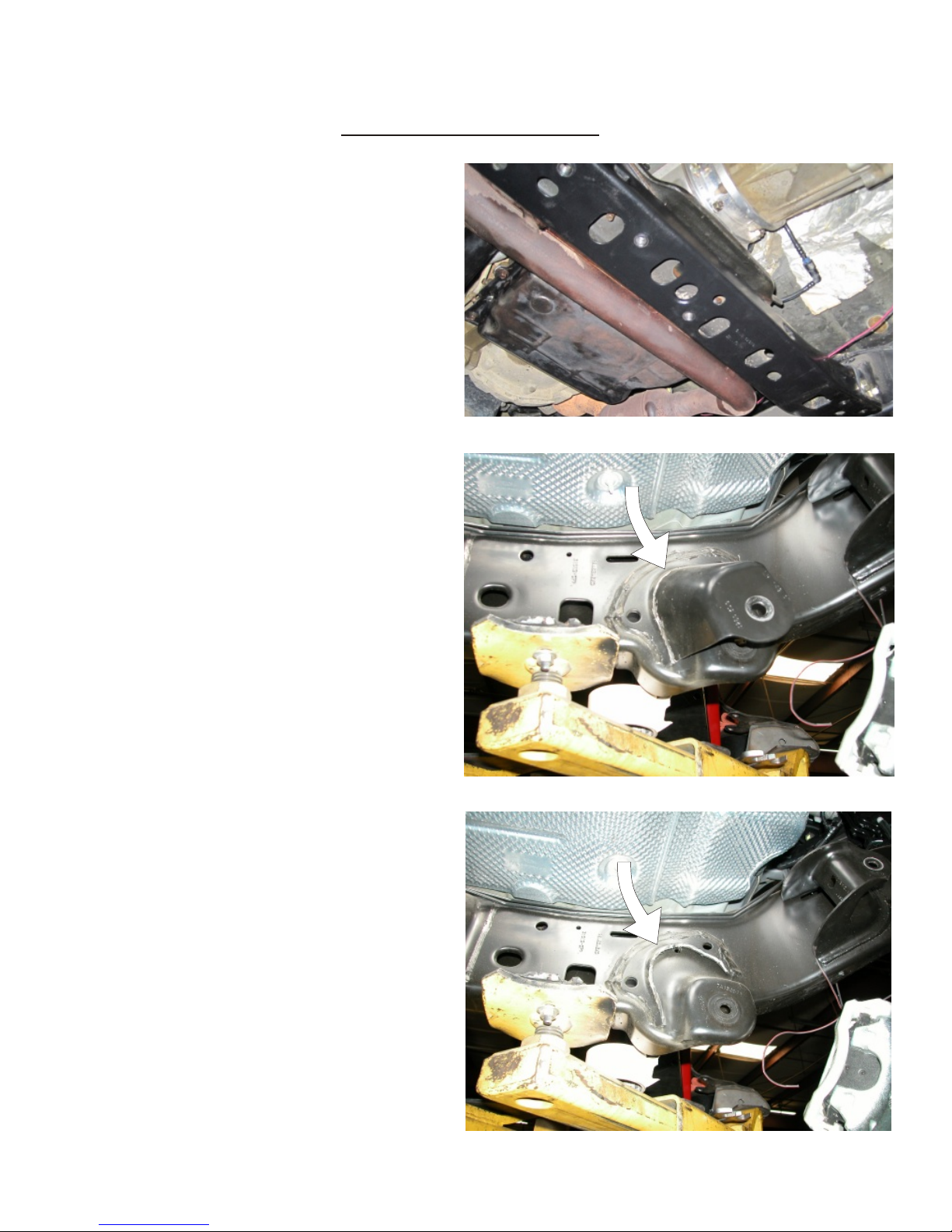

Before installing this system, have the vehicle’s alignment

checked by a certified technician. The alignment must be within

factory specifications and the frame of the vehicle must be sound

(no cracks, damage or corrosion).

Do not chrome, cad or zinc plate any of the components in this

system. Changing the coated surface of components will void the

warranty of your Full Traction Suspension.

This suspension system was developed using the following tire &

wheel combination: 35” x12.50 tire, 17 x 8 wheel with 4.5 inches

of wheel backspacing. Before installing any other combination,

consult your local tire and wheel specialist.

Mandatory Requirements

The required installation time for this system is approximately

12-15 hours. Installation time will vary. NO transfer case or

exhaust modifications are required for 2007-2009 or 2012

You’ve made a purchase of the best suspension system

available. For a correctly installed system, follow these

instructions. If you do not have the tools or are unsure of your

abilities, have this system installed by a certified technician.

FULL TRACTION SUSPENSION IS NOT RESPONSIBLE FOR

DAMAGE OR FAILURE RESULTING FROM AN IMPROPER OR

MODIFIED INSTALLATION.

ADDITIONAL INFORMATION

Congratulations on your purchase of the highest quality

suspension system available for the Jeep JK. Some of the

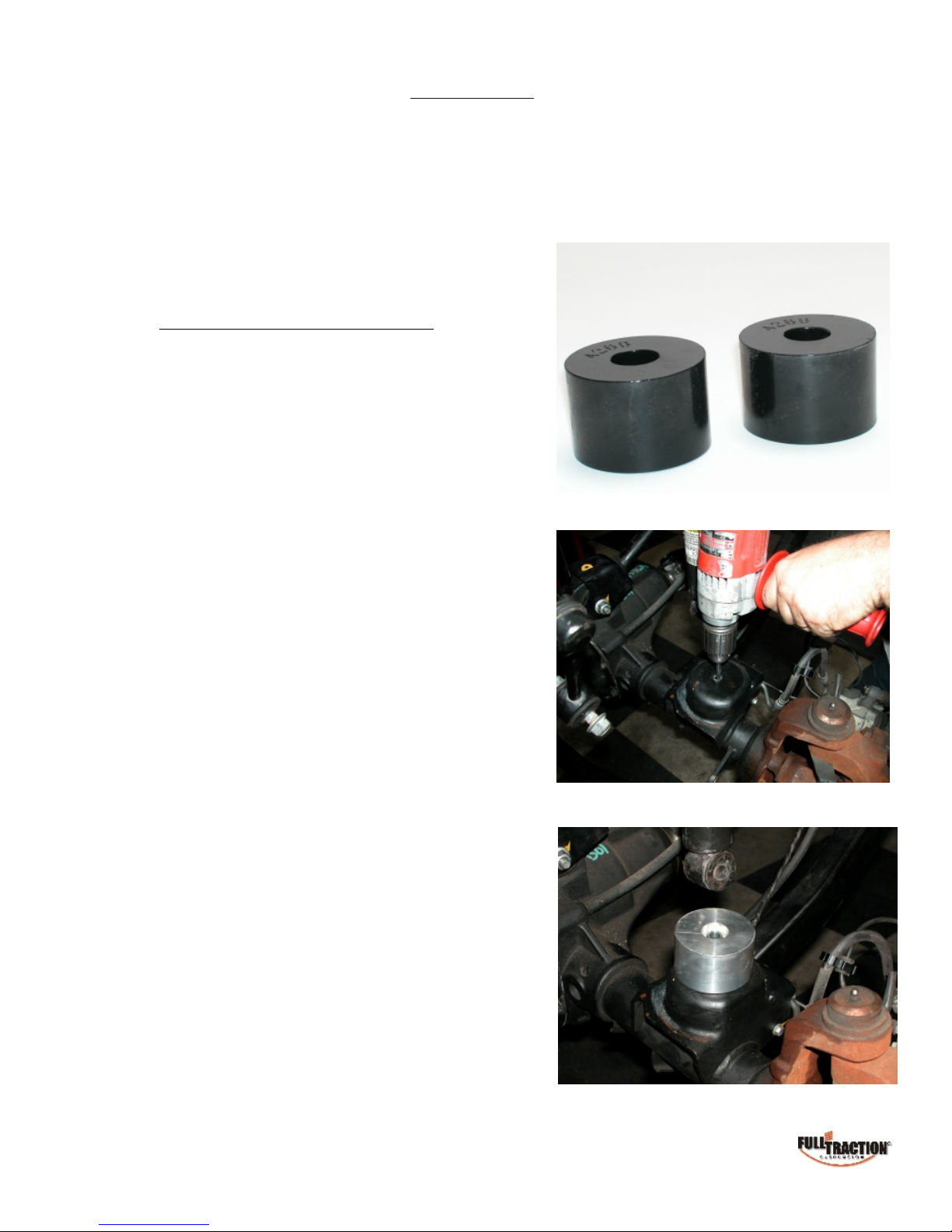

service procedures require the use of special tools designed for

specific procedures. The following common tools and supplies

are recommended for proper installation of this system,

However, not all of the items listed are required.

- Jeep Factory Service Manual

- Coil Spring Compressor

- Universal Steering Linkage Puller

- Ball Joint Separator

- Prevailing Torque Nuts (for steering linkage)

- Die Grinder

- Drill Motor

- Assorted Drills: 1/8” & larger

- Tie Down Strap

- Torque Wrench

- 1/2” drive Ratchet and Sockets

- Assorted Combination Wrenches

- Heavy Duty Jack Stands

- Wheel Chocks or Blocks

- Hydraulic Floor Jacks

- Center Punch

- File

- Large “C” Clamps, Bench Vise and Adjustable Straps.

- Hammer

- Hole Saw

- Wire Brush ( to clean mounting surfaces)

- Assembly Grease

- Tape measure

- Safety Glasses ( wear safety glasses at all times)

- Semi Gloss Black Spray Paint