★

★

If parameter identification is required, please pay attention that the rotating motor may injure

people, otherwise accident mayoccur!

Do not change the factory settings, otherwise the inverter may be damaged!

6. Running

★

★

★

Do not approach the equipment when restart functionis enabled, otherwise there will be danger

ofinjury.

Do not touch the fan and the discharging resistor to check the temperature, otherwise burning

mayoccur!

Non-professional person shall not measure the signalof a running inverter,otherwise there will

be danger ofinjury or damaging the inverter!

★

★

Do not let objects fall in a runninginverter, otherwise the inverter may be damaged!

Do not start and stop the inverter byon/off of the contactor, otherwise the inverter maybe

damaged!

7. Maintenance

★

★

★

Please do not repair or maintain the inverter withpoweron, otherwise there willbe danger of

electric shock!

Please repair or maintain the inverter after confirming the charge LED turns off, otherwise there

maybe human injury causedby the residual voltage of the capacitor!

Only qualified electrical engineer can repair or maintain the inverter, otherwise there will be

danger of human injury or damaging the equipment.

1.2

Cautions

1. Check the Insulation of the Motor

Whenthe motor is used for the first time, or reusedafterstoring for a long time, or in regular checkup,

the user must check the insulation of the motor toprevent the poor insulationof thewindings of motor from

damaging the inverter. The motor connection must be divided from the inverter during the insulation check.

It isrecommended to use a 500VMega-Ohm-Meter to check and the insulation resistance shall not be less

than5M .

2.Thermal Protection of Motor

If the rated capacity of the motor selected is not matching that of the inverter, especially when the rated

power of the inverter is bigger than that of the motor,make sure to adjust the parameters for motor protection

insidethe inverter or to install a thermal relay to the motorto guarantee the protection to the motor.

3.Running at Frequency Above Rated Frequency

The output frequency of this inverteris 0~600Hz. Please considerthe capability of themechanical

devices when the customer needs the inverter to run at the frequency higher than 50Hz.

4. Motor Heat andNoise

Since the output voltage of the inverter is in PWM wave with some harmonics,the temperature may rise,

the noise and vibration may increase compared with the inverter running at main frequency.

5.Pressure-sensitive Device or Capacitor at the Output Side of the Inverter

Because the inverter outputs PWM wave, the capacitor used for improving power factor andpressure-

sensitive resistor used forlightening-proof shouldn't be installed at the output side of the inverter, otherwise

the inverter may have transient over-current and maybe damaged.

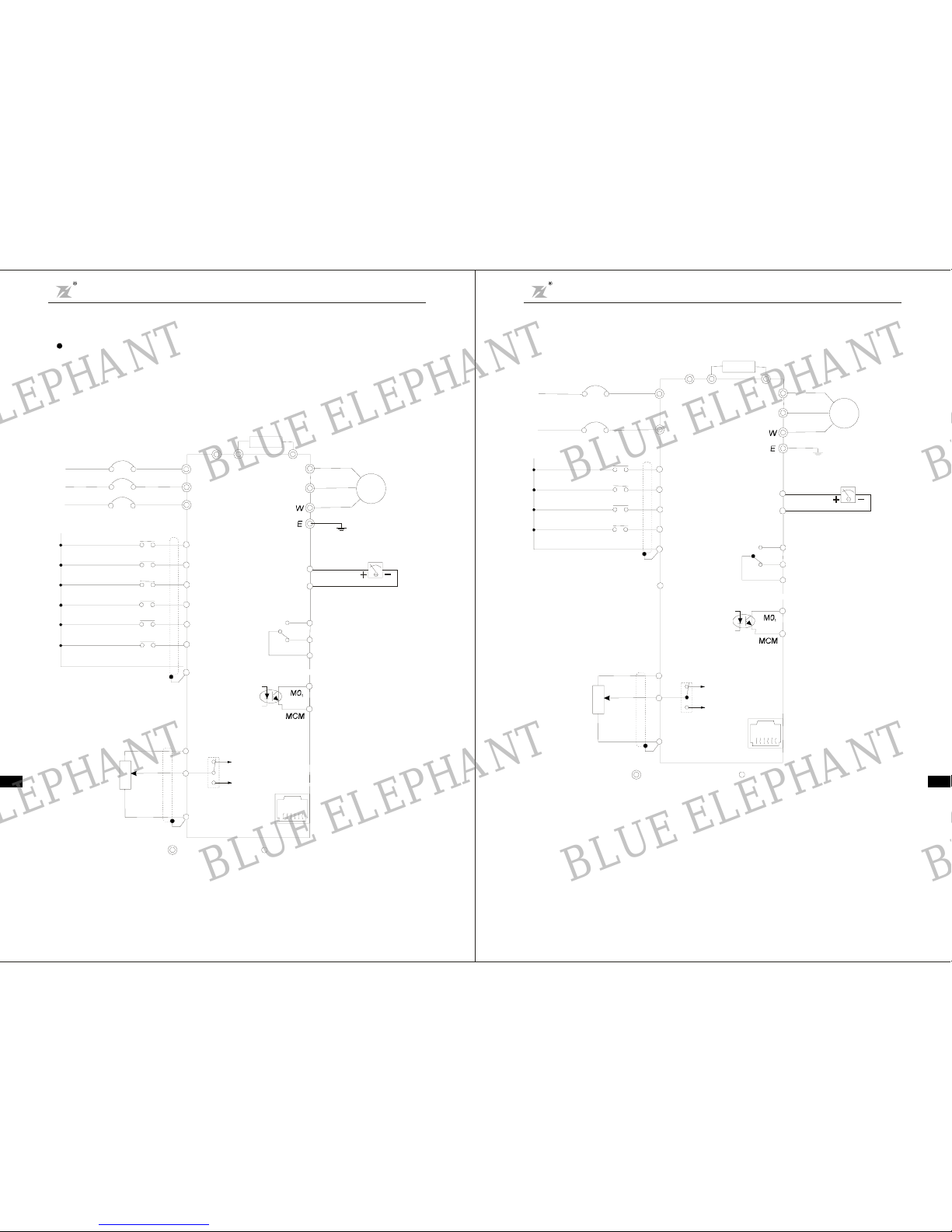

6.Switches Used at the Input andOutput terminal of the Inverter

If the contactor is required to be installed between the inverter and the power supply, it is prohibited to

start orstop the inverter with the contactor. Ifthe userhas to use the contactor to start and stop the inverter,

the interval between the start and stop shall be less than one hour. Frequent charging and discharging may

reducethe life of the capacitor. If the switches like contactors are connected between the output terminal and

the motor, make sure to start and stop the inverterwhen the inverterhasno output, otherwise the modules in

the inverter may be damaged.

7.Usage Outside the Range of Rated Voltage

The DZB series invertershall not be used out of the specified range of operation voltage, otherwise the

internal componentsof the inverter maybe damaged.If needed,please use corresponding voltage regulation

device tochange the voltage.

8. 3-phase InputModified Into 2-phase Input

The modificationof DZB series inverter from3-phase input to 2-phaseinput is not allowed,or fault may

occur.

9. Lightning Strike Protection

There are lightning protection devices inside the inverter, But the user should install other lightning

protection deviceat the frontend of the inverteriflightning strikeoccursfrequently.

10.Altitude and Deration

When the altitude is higher than 1000m, the cooling effect of inverter isdeteriorated because of the

rarefaction of air, the deration mustbe usedandplease consult our company for detailed technical support.

Ω

-3- -4-

Note

Note

Danger

Danger

DZB Series

Chapter1 Safety and Cautions

DZB Series

Chapter 1 Safety and Cautions

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT

BLUE ELEPHANT