Part # FA501D –Gas/Odor Filter

Most process plumes contain several gases, some odorous –some not, some toxic at elevated concentrations

–some completely harmless regardless of concentration. To ensure employee safety the type and

concentration of pollutants must be determined. Please contact Fumex Engineering for filter selection

assistance. These filters utilize a blended activated carbon and activated alumina impregnated with KMnO4

filter to capture and treat gases/odors. This combination of materials provides protection across a broad range

of gases commonly found in industrial manufacturing processes.

GENERAL MAINTENANCE

1) The blower motor(s) is a sealed unit, 24,000 hr. MTBF rated. It is permanently lubricated and does not require

oiling –keep it free of dust accumulations to prevent overheating.

2) Remove any loose accumulations of dust/debris from the air filter chamber periodically.

“This product employs overload protection (fuse). A blown fuse indicates an overload or short-circuit situation. If

the fuse blows, unplug the product from the receptacle. Replace the fuse as per the user servicing instructions

(use only 20-Amp fuse) and check the product. If the replacement fuse blows, a short circuit may be present, and

the product should be discarded or returned to an authorized service facility for examination and/or repair”.

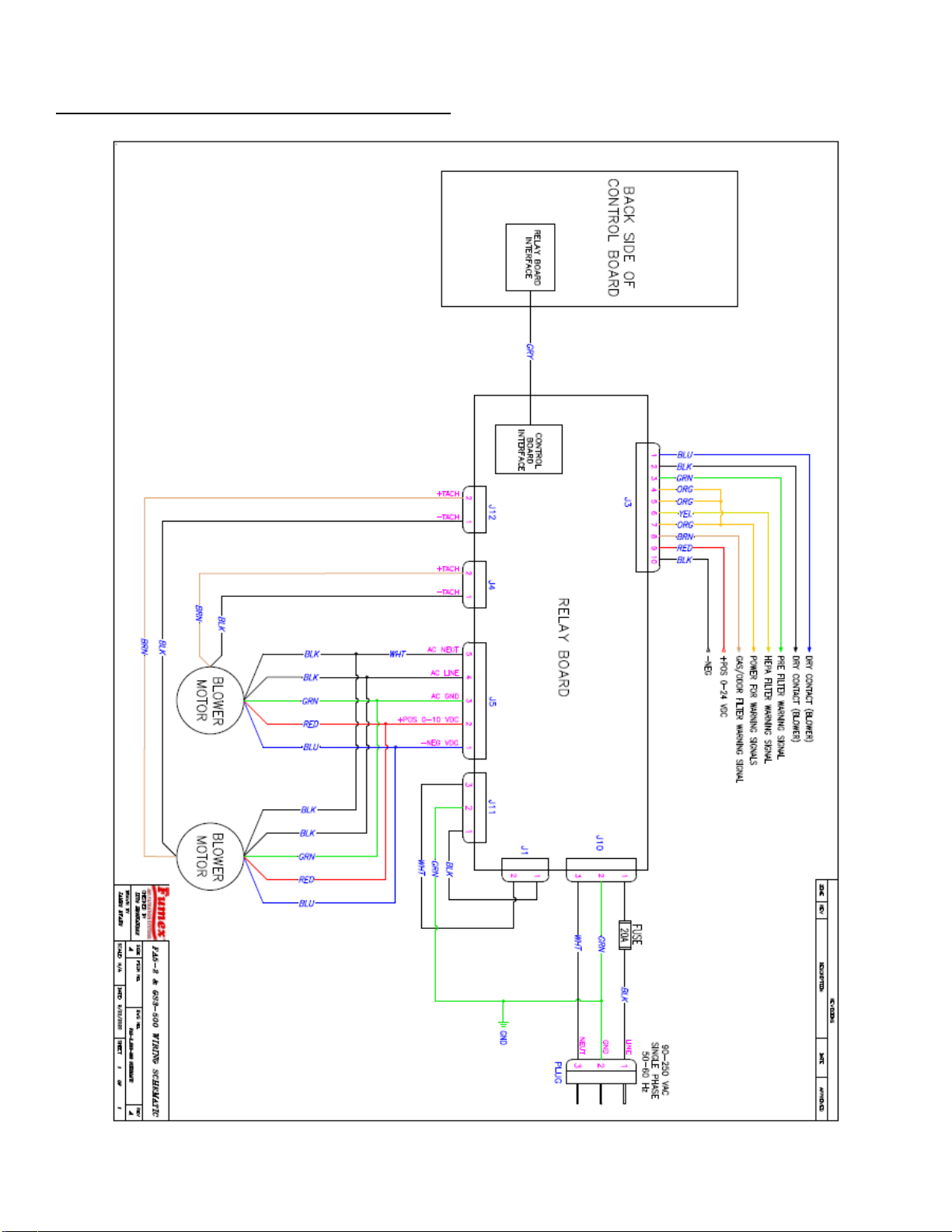

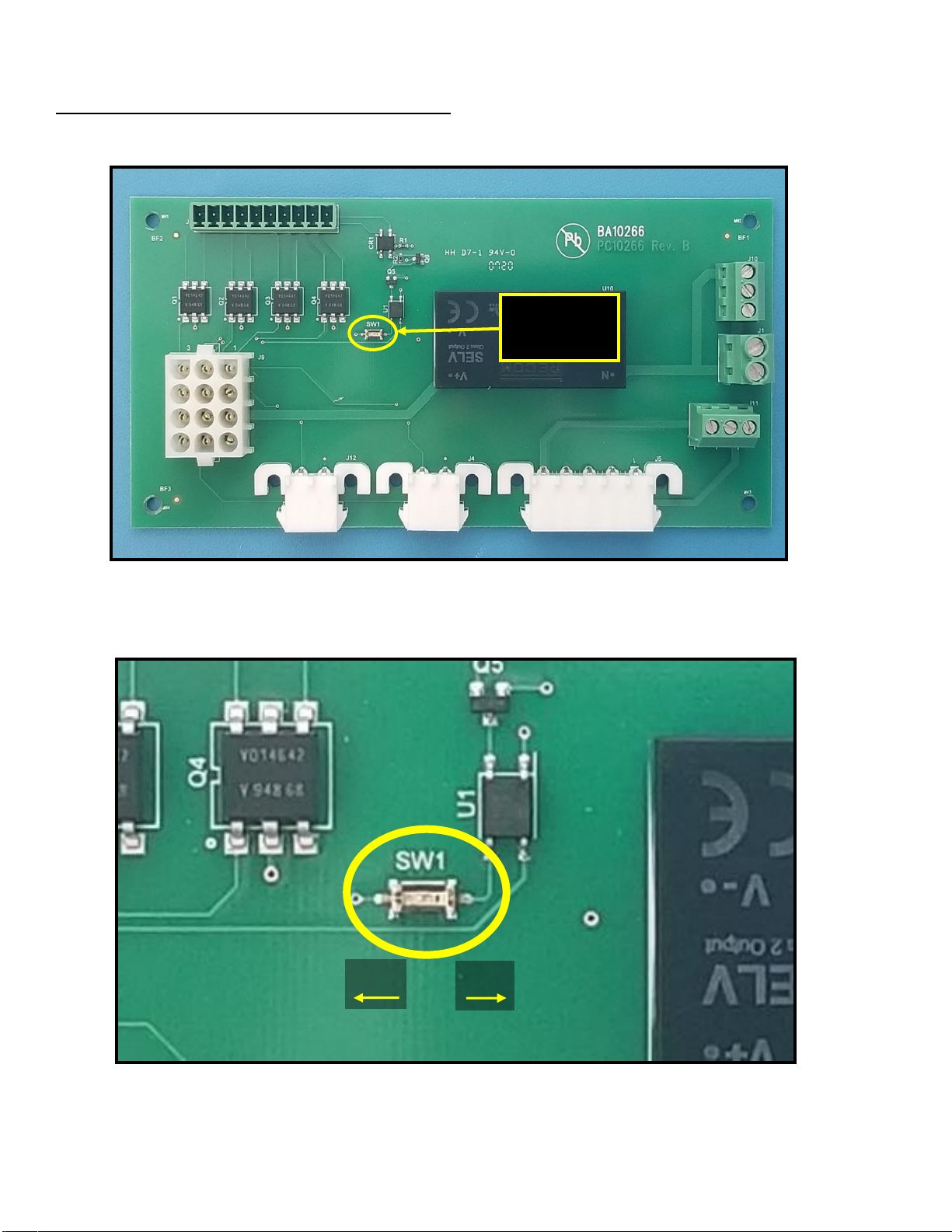

Remote Interface and Connectivity Function

The GS3-500 can be supplied with an optional interface package providing remote start/stop and filter monitoring

capabilities (Part # FA227). Please see instructions below for Relay Activation/De-Activation procedures and

refer to the drawing in Figure 1 for remote connections.

WARNING

“To Prevent the Risk of Electrical Shock, Connect Remote Interface

Cable to 24v, Class 2 Power Supply Only”

WARNING

“Disconnect from All Power Supplies Before Servicing”