Stainless steel transducer in a metal hull—To prevent

electrolytic corrosion, the stainless steel anti-rotation bolt must

be isolated from the metal hull. Slide the isolation sleeve over the

bedded anti-rotation bolt as far down as possible (Figure 6).

Apply a 2mm (1/16") thick layer of the marine sealant to the

outside of the sleeve.

2. Apply a 2mm (1/16") thick layer of marine sealant to the side of

the washer that will contact the backing block.

3. Push the anti-rotation bolt through the fairing and the hull.

4. From inside the hull, screw the washer (sealant side down) and

the nut onto the anti-rotation bolt.

Stainless steel transducer in a metal hull—Be sure the

isolation sleeve is between the anti-rotation bolt and the hull

(Figure 6). However, the isolation sleeve must be below the

washer and nut to prevent the sleeve from interfering with

tightening the nut.

5. Use slip-joint pliers to tighten the hull nut. Then tighten the nut

on the anti-rotation bolt. Do not over-tighten, crushing the

fairing or hull.

Cored fiberglass hull—Do not over tighten, crushing the hull.

Wood hull—Allow for the wood to swell before tightening the nut.

6. Use marine sealant to half-fill the hollow in the yellow triangular

plug. Apply a 2mm (1/16") thick layer of marine sealant to the

three sides of the plug that form the triangle. The sealant will

hold the plug firmly within the fairing and fill any gap between

the anti-rotation bolt and the plug.

7. The yellow triangular plug fits one way only. Push the yellow

plug into the recess in the fairing until it is FLUSH with the

outside of the fairing. This will squeeze out excess sealant. If

necessary, tap it into place with a mallet.

NOTE: If the triangular plug is slightly recessed within the

fairing, use sealant to fill the gap. The plug must be FLUSH with

the fairing for good performance.

8. When the boat is underway, especially at high speeds, water

will enter any gaps and push against the fairing with

considerable force, possibly rotating it. Fill any gaps between

the fairing and the hull with marine sealant. If there is any gap

greater than 3mm (1/8"), replace the fairing. Remove the

excess sealant on the outside of the fairing and hull to ensure

smooth water flow under the transducer.

Cable Routing & Connecting

CAUTION: If the sensor came with a connector, do not remove it

to ease cable routing. If a cable must be cut and spliced, use

Airmar’s splash-proof Junction Box No. 33-035 and follow the

instructions supplied. Removing the waterproof connector or

cutting the cable, except when using a water-tight junction box,

will void the sensor warranty.

1. Route the cables to the instrument being careful not to tear the

cable jacket when passing it through the bulkhead(s) and other

parts of the boat. Use grommet(s) to prevent chafing. To reduce

electrical interference, separate the transducer cables from

other electrical wiring and the engine. Coil any excess cable and

secure it in place with cable ties to prevent damage.

2. Refer to the instrument owner’s manual to connect the

transducer to the instrument.

Checking for Leaks

When the boat is placed in the water, immediately check around the

transducer for leaks. Note that very small leaks may not be readily

observed. Do not leave the boat in the water for more than 3 hours

before checking it again. If there is a small leak, there may be

considerable bilge water accumulation after 24 hours. If a leak is

observed, repeat “Bedding” and “Installing” immediately (see page 4).

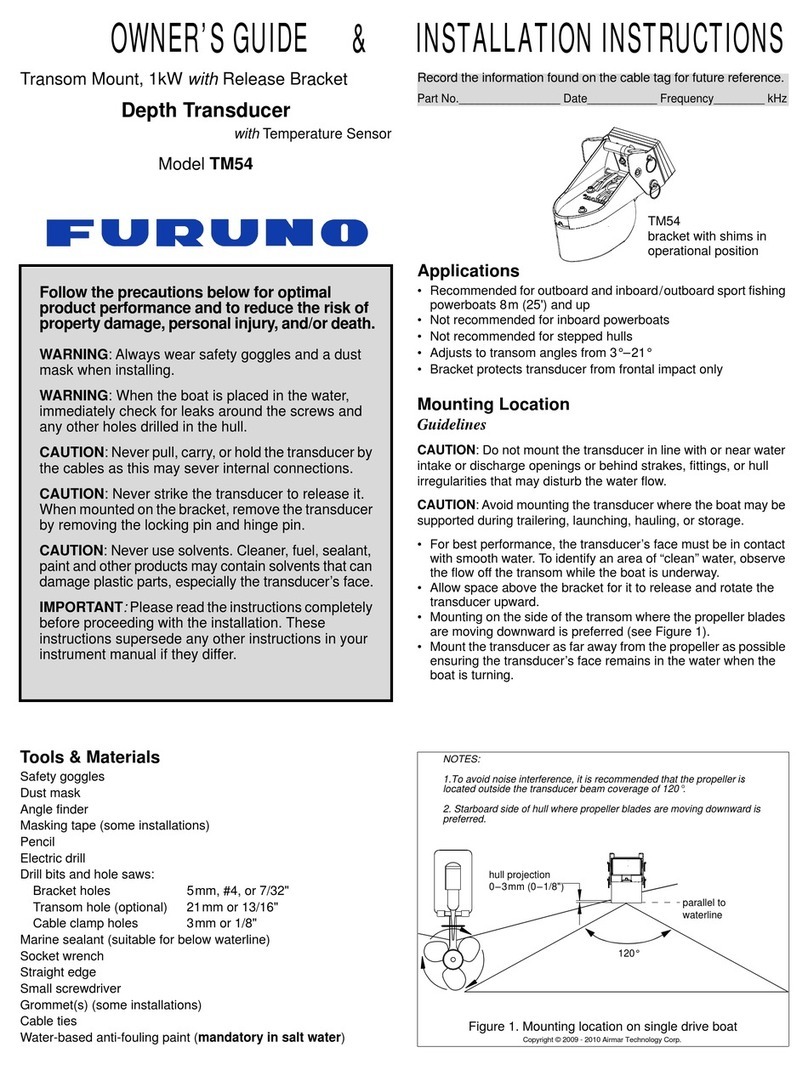

Installation in a Cored Fiberglass Hull

The core (wood or foam) must be cut and sealed carefully. The

core must be protected from water seepage, and the hull must be

reinforced to prevent it from crushing under the hull nut allowing

the transducer to become loose.

CAUTION: Completely seal the hull to prevent water seeping into

the core.

1. Drill a 3mm or 1/8" pilot hole perpendicular to the waterline from

inside the hull (Figure 7). If there is a rib, strut, or other hull

irregularity near the selected mounting location, drill from the

outside. If the hole is drilled in the wrong location, drill a second

hole in a better location. Apply masking tape to the outside of the

hull over the incorrect hole and fill it with epoxy.

2. Using the appropriate size drill bit or hole saw, cut a hole from

outside the hull through the outer skin only. Be sure to hold the

drill plumb, so the hole will be perpendicular to the water surface.

3. The optimal interior hole diameter is affected by the hull’s

thickness and deadrise angle. It must be large enough in

diameter to allow the core to be completely sealed.

Using the appropriate size drill bit or hole saw, cut through the

inner skin and most of the core from inside the hull keeping the

drill perpendicular to the hull. The core material can be very soft.

Apply only light pressure to the hole saw after cutting through the

inner skin to avoid accidentally cutting the outer skin.

4. Remove the plug of core material, so the inside of the outer skin

and the inner core of the hull is fully exposed. Sand and clean

the inner skin, core, and the outer skin around the hole.

5. Coat a hollow or solid cylinder of the correct diameter with wax

and tape it in place. Fill the gap between the cylinder and hull

with casting epoxy. After the epoxy has set, remove the cylinder.

6. Sand and clean the area around the hole, inside and outside, to

ensure that the sealant will adhere properly to the hull. If there

is any petroleum residue inside the hull, remove it with either

mild household detergent or a weak solvent, such as alcohol,

before sanding.

7. Follow the same procedure to prepare the hull for the anti-

rotation bolt. Repeat steps 1 through 6.

8. Proceed with the installation beginning with "Cutting the

Fairing" on page 3. Note that all holes are already drilled.

Anti-fouling Paint

Surfaces exposed to salt water must be coated with anti-fouling

paint. Use water-based anti-fouling paint only. Never use ketone-

based paint since ketones can attack many plastics possibly

damaging the transducer. Reapply anti-fouling paint every 6

months or at the beginning of each boating season.

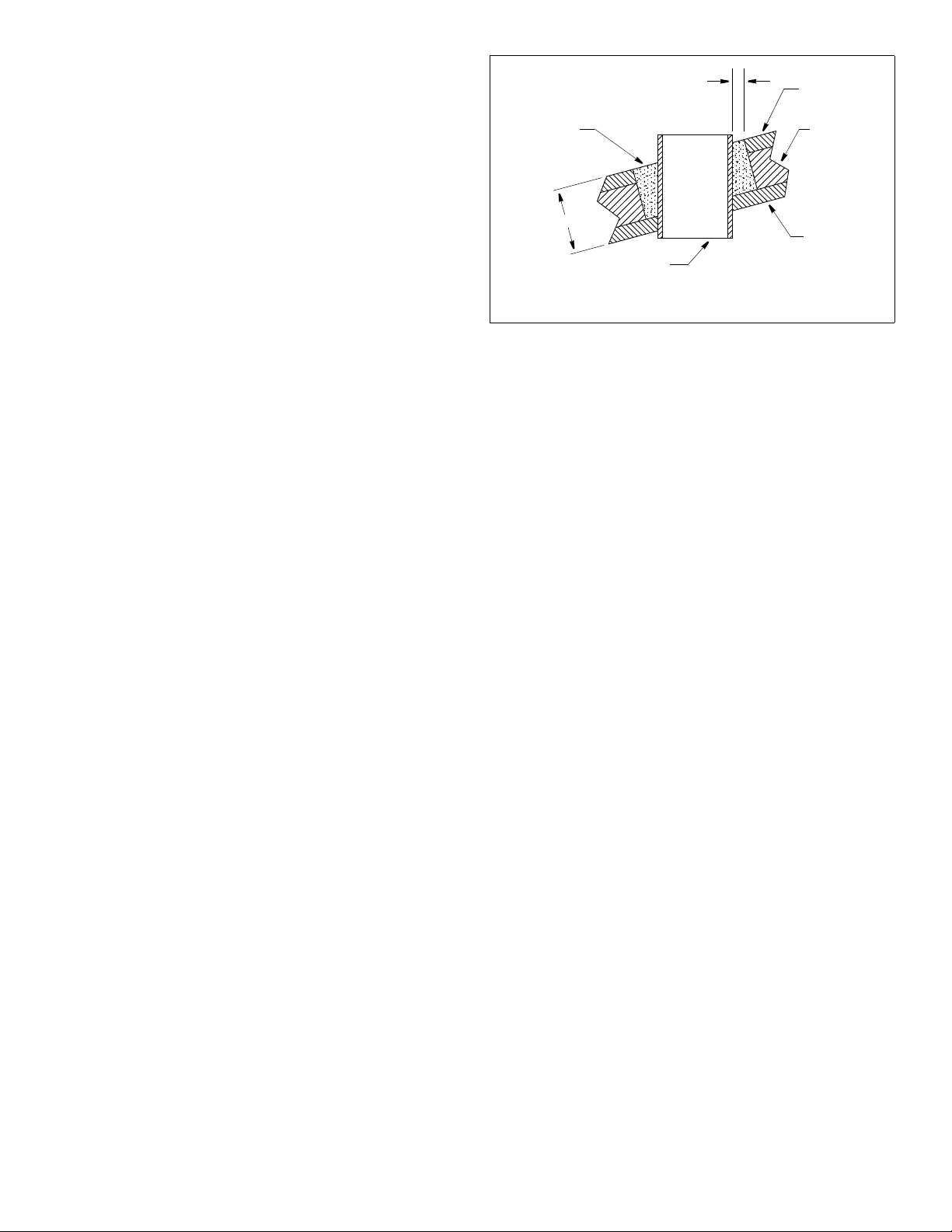

hull’s outer skin to

hull

outer skin

solid or hollow

cylinder

pour in

casting

epoxy

core

inner skin

Figure 7. Preparing a cored fiberglass hull

Dimension equal to

the thickness of the

ensure adequate

clearance

Copyright © 2005 Airmar Technology Corp.

5