Laser Safety

The use of controls, adjustments, or the performance of procedures other than

those specied herein may result in hazardous radiation exposure.

Do Not stare into the laser beams.

Do Not disassemble the instrument or attempt

to perform any internal servicing. Repair and

servicing of this laser are to be performed only

by a Futtura authorized service centre.

This laser complies with all applicable portions

of title 21 of the Code of Federal Regulations se by the Department of Health,

Education, and Welfare, The Food and Drug Administration, the Centre for

Devices, and the Bureau of Radiological Health.

Warranty

LT-850 . 3

The Futtura LT-850 Laser is warranted to the original purchaser to be

free from defects in workmanship and material. Futtura will repair or

replace any defective part which may malfunction under normal and

proper use within a period of TWO YEARS from the date of purchase

without charge of parts and labor, once delivered and shipped prepaid

to Futtura together with proof of date and place of purchase. This

warranty is not subject to misuse, abuse, assignment, or transfer. The

exclusive remedy under any and all warrants and guarantees, ex-

pressed or implied, is limited to repair and/or replacement as provided

herein, and Futtura shall not be liable for damages from loss or delay

of equipment uses, consequential, or incidental damage.

Laser Safety

The use of controls, adjustments, or the performance of procedures other than

those specied herein may result in hazardous radiation exposure.

Do Not stare into the laser beams.

Do Not disassemble the instrument or attempt

to perform any internal servicing. Repair and

servicing of this laser are to be performed only

by a Futtura authorized service centre.

This laser complies with all applicable portions

of title 21 of the Code of Federal Regulations se by the Department of Health,

Education, and Welfare, The Food and Drug Administration, the Centre for

Devices, and the Bureau of Radiological Health.

Warranty

LT-850 . 3

The Futtura LT-850 Laser is warranted to the original purchaser to be

free from defects in workmanship and material. Futtura will repair or

replace any defective part which may malfunction under normal and

proper use within a period of Two Years from the date of purchase

without charge of parts and labor, once delivered and shipped prepaid

to Futtura together with proof of date and place of purchase. This

warranty is not subject to misuse, abuse, assignment, or transfer. The

exclusive remedy under any and all warrants and guarantees, ex-

pressed or implied, is limited to repair and/or replacement as provided

herein, and Futtura shall not be liable for damages from loss or delay

of equipment uses, consequential, or incidental damage.

14 . LT-850

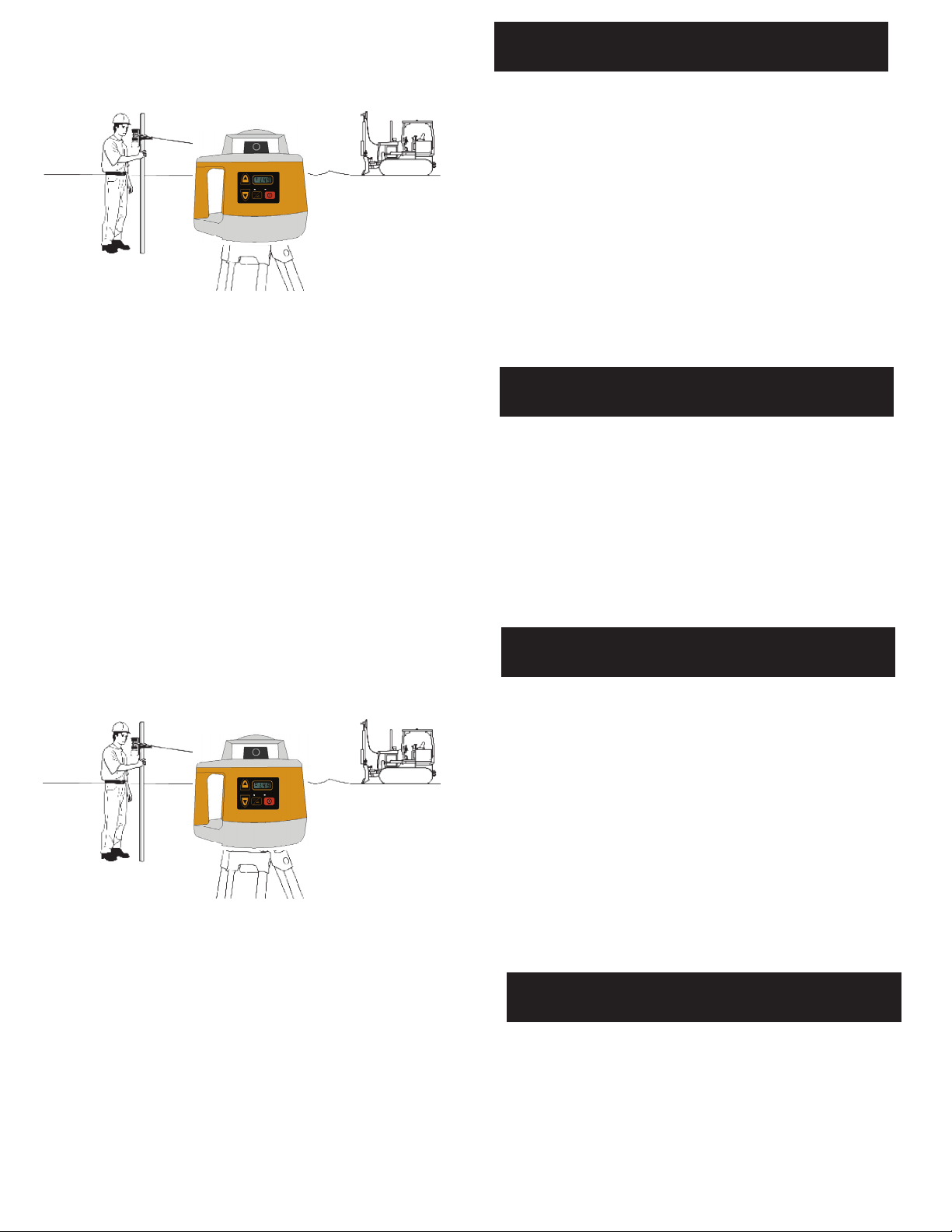

Calibration LT-850

Your LT-850 Self-Leveling Grade Laser is a sealed unit and is

calibrated to precise accuracies at the factory. However, if a cali-

bration error is present, we recommend you have your unit

calibrated at a certied Futtura Service Center.

Field calibration is possible if great care taken in following these

instructions.

Upright Position Calibration – X and Y axis

1) To Calibrate the X axis, mount the laser on a tripod or a level,

sturdy surface and place approximately 100 feet (30m) away from

a wall. Face the X axis of the unit to the wall.

2) Establish the new calibration point (C), following the instruction

in Calibration Test.

3) Turn the unit off, then turn the unit back on holding the Mode

Button.

4) The display will now read Co.1 or Co.2 and the laser beam

will turn on and the unit will rotate. Press the mode button until

the display reads Co.1. Now the display will alternate between

Co.1 and a calibration value, which can be a positive or negative

number.

5) Move the detector to the new calibration point (C). With the

Plus and Minus Buttons, increase or decrease the calibration

value until the laser beam moves to the new calibration point.

6) Press the mode button until the display shows Co.2. Repeat 4

and 5 for the Y axis.

7) Pressing the Power button once will store the new calibration

values and then put the unit into the Flat Mode.

8) Follow the Calibration Test instructions to verify the unit is now

calibrated.

14 . LT-850

Calibration LT-850

Your LT-850 Self-Leveling Grade Laser is a sealed unit and is

calibrated to precise accuracies at the factory. However, if a cali-

bration error is present, we recommend you have your unit

calibrated at a certied Futtura Service Center.

Field calibration is possible if great care taken in following these

instructions.

Upright Position Calibration – X and Y axis

1) To Calibrate the X axis, mount the laser on a tripod or a level,

sturdy surface and place approximately 100 feet (30m) away from

a wall. Face the X axis of the unit to the wall.

2) Establish the new calibration point (C), following the instruction

in Calibration Test.

3) Turn the unit off, then turn the unit back on holding the Mode

Button.

4) The display will now read Co.1 or Co.2 and the laser beam will

turn on and the unit will rotate. Press the mode button until the

display reads Co.1. Now the display will alternate between Co.1

and a calibration value, which can be a positive or negative num-

ber. When the laser has leveled itself, it will read Lo.1

5) Move the detector to the new calibration point (C). With the

Plus and Minus Buttons, increase or decrease the calibration

value until the laser beam moves to the new calibration point.

6) Press the mode button until the display shows Co.2. Wait for it

to level and read Lo.2, then repeat 4 and 5 for the Y axis.

7) Pressing the Power button once will store the new calibration

values and then put the unit into the Flat Mode.

8) Follow the Calibration Test instructions to verify the unit is now

calibrated.