The limit control L41 is a microprocessor based high or low limit

safety device with a latching output. The relay contacts open if

an abnormal condition during the process is higher than the

high limit set point or lower than the low limit set point.

The unit is powered by 90-250 VAC or an optional 11-26

VAC/VDC power supply. It incorporates a 2 amp. form C relay for

limit control, a universal input which is fully programmable for

RTD PT100, thermocouple types J, K, T, E, B, R, S, N, L, 0~60mVolt,

Volt* and Milliamps*. Alternative main outputs are SSRD or Triac.

A second optional output is available. This output can be

configured for additional alarm or annunicator type output.

A DC power supply output option is available for external sensor

or transmitter excitation power. The standard event input can be

programmed for remote reset or remote lock signal input.

Ma/VDC retransmission option of Process variable or setpoint is

also available.

Digital communication RS-485 is available as an additional

option. This option allows L91 to be integrated with supervisory

control system.

Note; Retransmission and Communications is mutually exclusive.

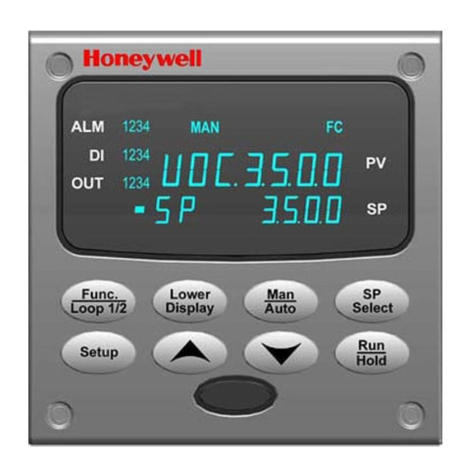

Two kinds of method can be used to program L91.

1. use keys on front panel to program the unit manually.

2. Use a PC and setup software to program the unit via

standard configuration port.

The input signal is digitized by using a 18-bit A to D converter. Its

fast sampling rate (5 times/second) allows the L91 to respond

quickly to input changes.

High accuracy, maximum flexibility, fast response and simple

user friendly prompts are the main features of L91.

NOTE: * Volt and Milliamp Inputs are NOT FM Approved.

L41

Two kinds of method can be used to program L91.

1. use keys on front panel to program the unit manually.

2. Use a PC and setup software to program the unit via

standard configuration port.

18-bit A to D

fast sampling rate

High accuracy, maximum flexibility, fast response

user friendly prompts

The unit is powered by 90-250 VAC or an optional 11-26

VAC/VDC power supply. It incorporates a 2 amp. form C relay for

limit control, a universal input which is fully programmable for

RTD PT100, thermocouple types J, K, T, E, B, R, S, N, L, 0~60mVolt,

Volt* and Milliamps*. Alternative main outputs are SSRD or Triac.

A second optional output is available. This output can be

configured for additional alarm or annunicator type output.

The input signal is digitized by using a converter. Its

(5 times/second) allows the L91 to respond

quickly to input changes.

Chapter 1OverviewChapter 1Overview

1-1 General1-1 General

5

UM L41-Rev 2