L22/L62/L42 Process Limit Control

3

TABLE OF CONTENTS

1 Introduction ................................................................................................................5

1.1 Why Use a Limit Control?..........................................................................................5

1.2 Features....................................................................................................................5

1.3 Specifications............................................................................................................6

1.4 Ordering Code...........................................................................................................9

1.4.1 L42 Ordering Code ..........................................................................................................................9

1.4.2 L62 Ordering Code ........................................................................................................................10

1.4.3 L22 Ordering Code ........................................................................................................................11

1.4.4 Accessories ...................................................................................................................................11

1.4.5 Related Products ...........................................................................................................................11

1.5 Programming Port...................................................................................................12

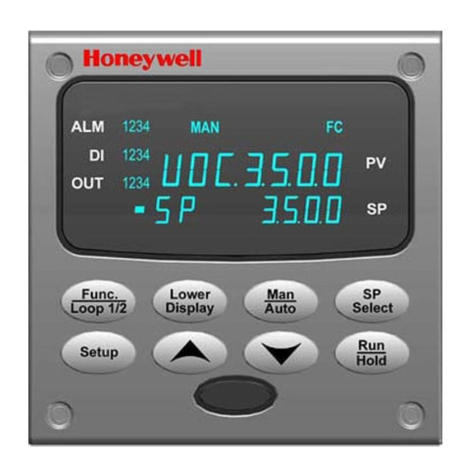

1.6 Keys and Displays...................................................................................................13

1.6.1 Keypad Operation..........................................................................................................................14

1.6.2 Display Operation ..........................................................................................................................15

1.7 Menu Navigation .....................................................................................................16

1.7.1 User Access Menu.........................................................................................................................17

1.7.1.1 Reference Data ......................................................................................................................17

1.7.2 Setup Menu ...................................................................................................................................18

1.7.2.1 Basic Menu (bASE)................................................................................................................19

1.7.2.2 Communication Menu (CoMM) ..............................................................................................20

1.7.2.3 User Select Menu (SEL).........................................................................................................20

1.7.2.4 Event Input Menu (EI) ............................................................................................................21

1.7.2.5 Alarm Menu (ALRM)...............................................................................................................21

1.7.2.6 Output Menu (OUT)................................................................................................................22

1.7.3 Calibration Menu............................................................................................................................23

1.8 Parameter Availability..............................................................................................24

1.9 Parameter Description.............................................................................................26

2 Installation and Wiring.............................................................................................32

2.1 Enclosure Guidelines ..............................................................................................32

2.2 Mounting .................................................................................................................32

2.2.1 L42 Dimensions.............................................................................................................................33

2.2.2 L62 Dimensions.............................................................................................................................34

2.2.3 L22 Dimensions.............................................................................................................................35

2.3 Wiring Precautions..................................................................................................36

2.3.1 L42 Terminal Connections.............................................................................................................36

2.3.2 L62 Terminal Connections.............................................................................................................37

2.3.3 L22 Terminal Connections.............................................................................................................37

2.4 Power Wiring...........................................................................................................38

2.5 Sensor Installation...................................................................................................38

2.5.1 Sensor Input Wiring.......................................................................................................................39

2.6 Limit Control Output Wiring.....................................................................................40

2.7 Alarm Wiring............................................................................................................41

2.7.1 Alarm 1 (Output 2) .........................................................................................................................41

2.7.2 Alarm 2...........................................................................................................................................41

2.7.3 Alarm 3...........................................................................................................................................41