RSC_User_Manual_01C12_01-20-21 Page 3of 45

TABLE OF CONTENTS

1INTRODUCTION---------------------------------------------------------------------------------------------------------- 6

1.1 Introduction -------------------------------------------------------------------------------------------------------------------------------------- 6

1.2 Features ------------------------------------------------------------------------------------------------------------------------------------------- 6

1.3 Specifications------------------------------------------------------------------------------------------------------------------------------------ 8

1.4 Ordering Code ----------------------------------------------------------------------------------------------------------------------------------10

1.4.1 Accessories ------------------------------------------------------------------------------------------------------------------------------10

1.4.2 Related Products -----------------------------------------------------------------------------------------------------------------------10

1.5 Programming Port-----------------------------------------------------------------------------------------------------------------------------10

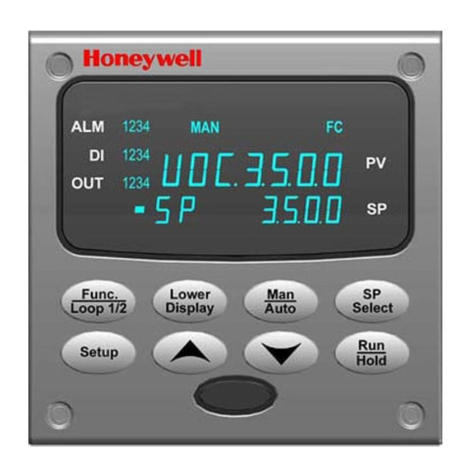

1.6 Display Board Keys---------------------------------------------------------------------------------------------------------------------------11

1.7 Menu Flowchart --------------------------------------------------------------------------------------------------------------------------------12

1.7.1 Basic Menu-------------------------------------------------------------------------------------------------------------------------------12

1.7.2 Output Menu (oUt) ---------------------------------------------------------------------------------------------------------------------13

1.7.3 Communication Menu (CoMM)------------------------------------------------------------------------------------------------------14

1.7.4 Manual Mode Menu--------------------------------------------------------------------------------------------------------------------15

1.7.5 Calibration Mode------------------------------------------------------------------------------------------------------------------------16

1.8 Parameter Availability Table ---------------------------------------------------------------------------------------------------------------16

1.9 Parameters Description ---------------------------------------------------------------------------------------------------------------------18

2INSTALLATION AND WIRING --------------------------------------------------------------------------------------24

2.1 Unpacking----------------------------------------------------------------------------------------------------------------------------------------24

2.2 Dimension----------------------------------------------------------------------------------------------------------------------------------------25

2.3 Wiring ---------------------------------------------------------------------------------------------------------------------------------------------26

2.3.1 Terminal Connection-------------------------------------------------------------------------------------------------------------------26

2.3.2 Power Wiring ----------------------------------------------------------------------------------------------------------------------------26

2.3.3 Sensor Installation----------------------------------------------------------------------------------------------------------------------27

2.3.4 Input Wiring ------------------------------------------------------------------------------------------------------------------------------27

2.3.5 Retransmission Output Wiring-------------------------------------------------------------------------------------------------------28

2.3.5.1 Output 1 --------------------------------------------------------------------------------------------------------------------------28

2.3.5.2 Output 2 --------------------------------------------------------------------------------------------------------------------------28

2.3.5.3 Output 3 --------------------------------------------------------------------------------------------------------------------------29

2.3.6 Digital Input Wiring ---------------------------------------------------------------------------------------------------------------------29

2.3.7 RS-485 Data Communication -------------------------------------------------------------------------------------------------------30

3PROGRAMMING --------------------------------------------------------------------------------------------------------31

3.1 User Security------------------------------------------------------------------------------------------------------------------------------------31

3.2 Calibration Password ------------------------------------------------------------------------------------------------------------------------31

3.3 Signal Input--------------------------------------------------------------------------------------------------------------------------------------31

3.4 Output Type -------------------------------------------------------------------------------------------------------------------------------------32

3.5 Retransmission --------------------------------------------------------------------------------------------------------------------------------32

3.6 Zero and Span adjustment -----------------------------------------------------------------------------------------------------------------32

3.7 Square Root function (SQRT) -------------------------------------------------------------------------------------------------------------32

3.8 User Calibration--------------------------------------------------------------------------------------------------------------------------------33

3.9 Digital Filter--------------------------------------------------------------------------------------------------------------------------------------33

3.10 Manual Control-----------------------------------------------------------------------------------------------------------------------------34

3.11 Factory Default-----------------------------------------------------------------------------------------------------------------------------34

3.12 Data Communication---------------------------------------------------------------------------------------------------------------------34

3.12.1 RS-485 Setup -----------------------------------------------------------------------------------------------------------------------34

3.13 Digital Input ---------------------------------------------------------------------------------------------------------------------------------34

3.13.1 Digital Input Functions ------------------------------------------------------------------------------------------------------------35