3

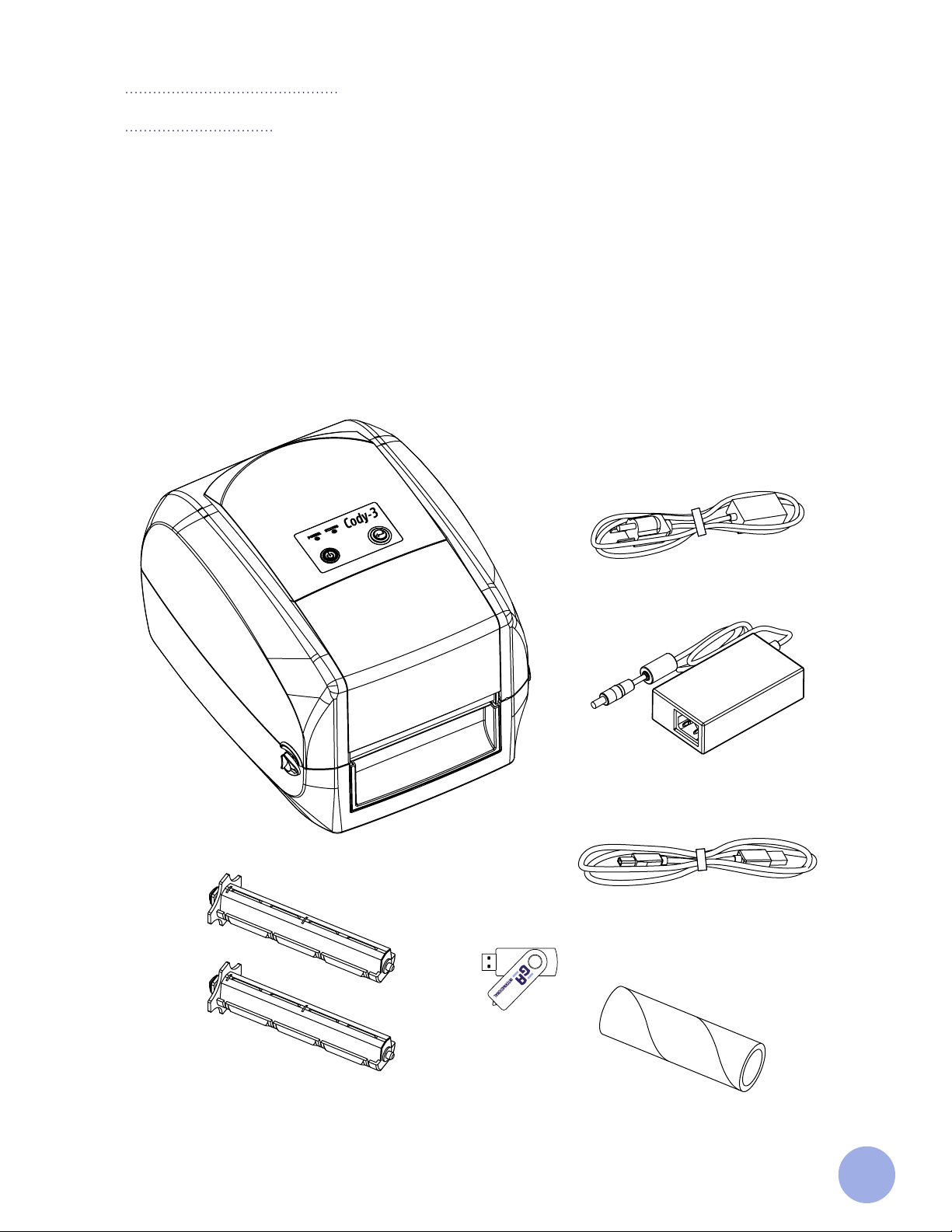

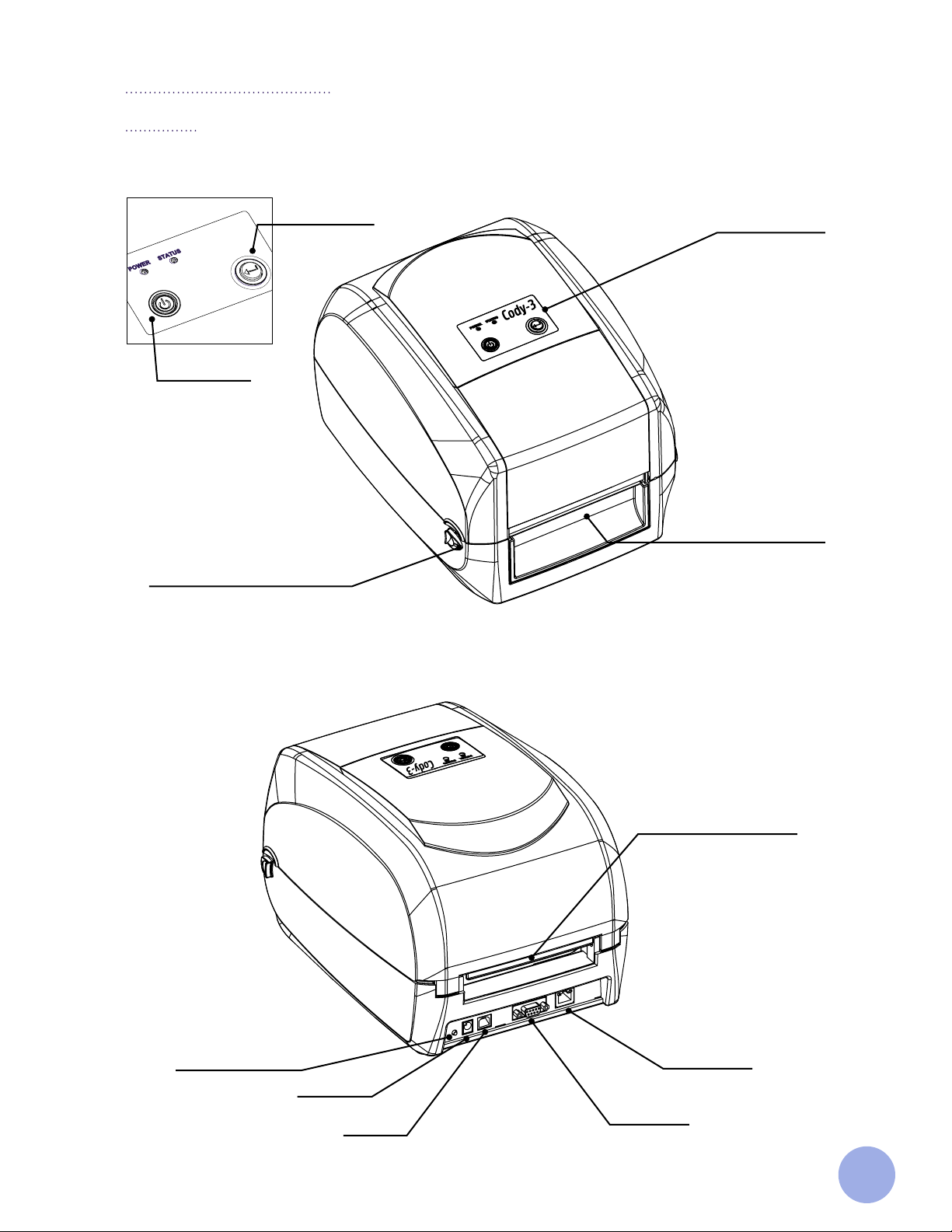

The Printer

Introduction

Thank you for choosing the Cody-3™ thermal-transfer and direct thermal printer.

This printer is built with two sets of gears to drive the motor and can handle 300 meters of ribbon and large

label rolls. The printer’s inner volume fits 5” OD (Outer Diameter) media rolls.

The Cody-3 is designed for real-time and batch label printing, with standard serial, USB, and Ethernet

connection ports. Thermal-transfer and direct thermal printing modes are both available so that you can

choose various kinds of printing materials.

Common 1D barcode and 2D barcode fonts are built into the printer. It supports 4-direction printing, and

characters can be enlarged from 1 to 8 times. The printer also supports eight dierent size bitmap fonts as

well as OCR-A and OCR-B fonts, making this printer the best choice among printers of the same class.

Instructions for Proper Use and Precautions

• The printer should only be used in a dry environment, do not expose it to moisture (sprays of water,

mists, etc.).

• Do not use the printer in an explosive atmosphere (under atmospheric conditions with a mixture of

dangerous substances in the air).

• The printer should not be used close to high-voltage power lines.

• If operating the printer with the cover open, ensure that any clothing, hair, jewelry, etc., does not contact

exposed rotating parts.

• Printer operation should be limited to only those actions outlined in the user manual. Work beyond this

may only be performed by trained personnel or certified service technicians.

• The printer should always be stored and operated under the recommended environmental conditions

(Please see page 5 of this manual).

• This product may cause radio interference, and users may need to take adequate preventive measures.

• The user must take proper care to avoid potential electric shock hazards.

• Precautions should be taken by the user to prevent possible burn risks (e.g., the printhead may become

hot and cause severe burns. Allow the printhead to cool before manipulating it).

• Care should be taken when handling the product to ensure it is not damaged (e.g., dropping the printer,

spilling liquids/chemicals into the printer, using dierent power voltage than specified).

• If care is not taken, the product’s electronics could be damaged by an electrostatic discharge (e.g.,

always observe proper electrostatic safety precautions when handling static-sensitive components

such as PC boards and printheads. Switch o all aected devices, such as computers, printers, and

accessories, before connecting or disconnecting them).

Limitation of Liability

In no event shall GA International Inc., its ailiates, or any of the parties involved in the creation, production, or

delivery of the accompanying product (including hardware and software) be liable for any loss, inconvenience,

or damage whatsoever, whether direct, indirect, special, incidental, consequential or otherwise (including,

without limitation, consequential damages including loss of business profits, business interruption, or loss of

business information/data) arising out of the use of, the results of the use of, or inability to use the product,

even if GA International Inc. has been advised of the possibility of such damages.