6

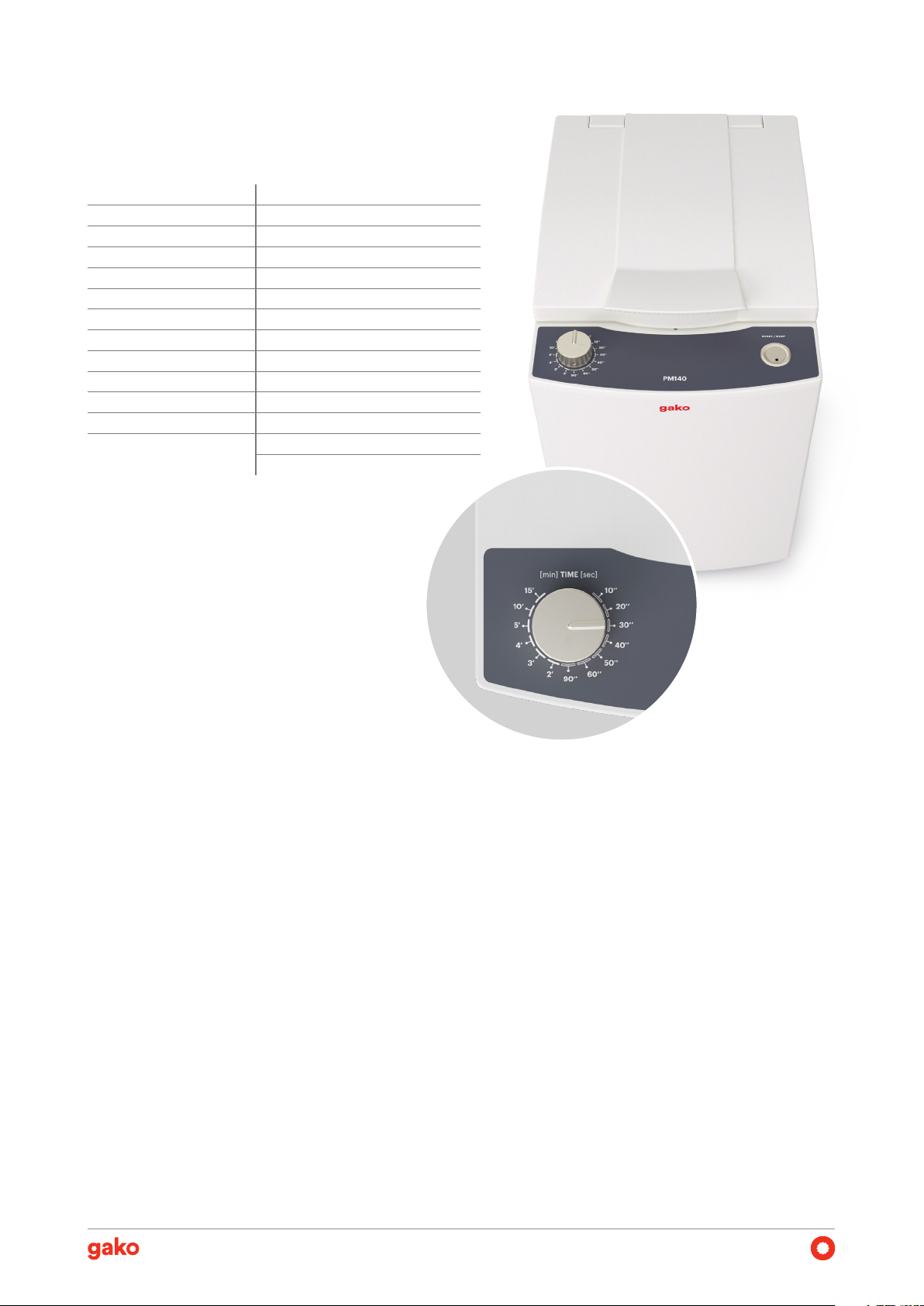

1.3. Key Features

Single-Step Process

The gako PM140 combines mixing, melting, and deaer-

ation processes in a single step. Therefore, it simpliies

the compounding of pharmaceutical preparations and

saves time while ensuring high-quality formulations. As

demonstrated in studies conducted by our scientiic ex-

pert team, the temperature rise is limited to 45°C, mak-

ing it suitable for most heat-sensitive ingredients.

Time-Saving

The high mixing speed of gako PM140 is ixed to 2800

rpm, allowing the preparation of formulations in less than

60 seconds.

Dosage Accuracy

In volume-dependent doses, as in HRT creams, a reliable

mixing process that deaerates the formulation improves

API distribution and ensures dosage accuracy for each

application.

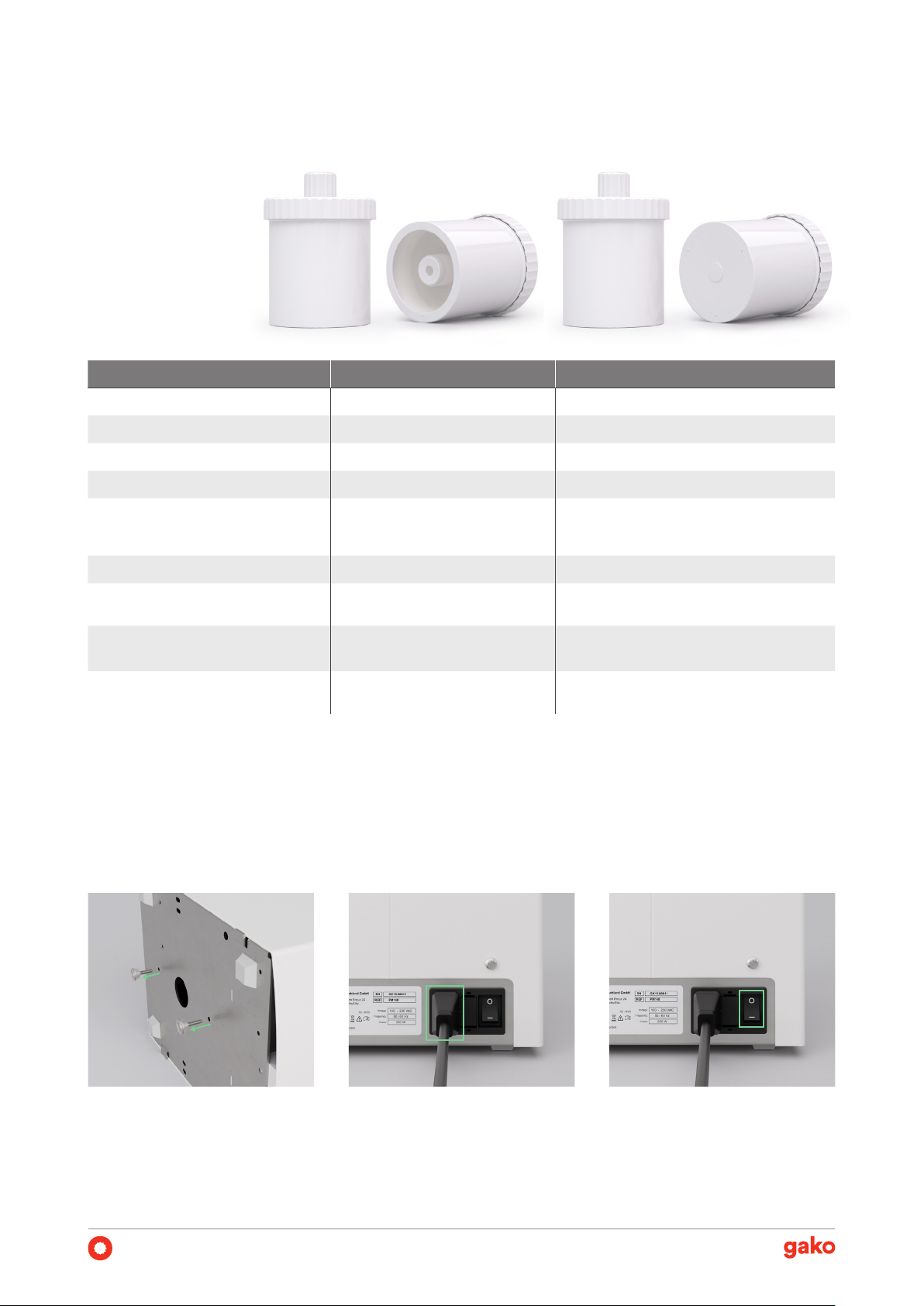

Material-Loss Prevention

In traditional mixing processes, material loss occurs dur-

ing the transfer to the inal package after mixing. Even if

the exact amounts are calculated and weighed, the com-

pounded preparation is never completely transferred

from the mortar into the package, especially when work-

ing with semi-solid dosage forms. To prevent material

loss, the gako PM140 is designed to mix the formulation

in a disposable PM jar, also used as a inal package to be

delivered to the patient.

Conservation of Resources

The gako PM140 contributes to water conservation, as it

does not require subsequent washing and rinsing steps

of spare parts such as blades and mixing rods.

Low-Maintenance

The gako PM140 is distinguished by quality materials

that allow for a low-maintenance and durable service,

improving cost-eiciency. Due to its compact and func-

tional design, the device can be easily integrated into lab

furniture or used on the workbench. It also eliminates

issues when compounding colored ingredients, such as

coloring the blades or wearing them out by changing

color and avoiding cross-contamination in a hormone

preparation through the edges.

Compounding Hazardous Drugs

The term “hazardous drug” (HD) was irst described by

the American Society of Health-System Pharmacists

(ASHP) in 1990 and has also been used by Occupational

Safety and Health Administration (OSHA) for compounds

that display the following characteristics: genotoxicity;

carcinogenicity; teratogenicity or loss of fertility; and

severe toxic manifestations at low doses in experiments

with animals or treated patients. An API is considered

hazardous if it features one or more of these characteris-

tics, and new APIs with structure and toxicity proiles that

mimic those of hazardous APIs are also classiied as HDs.

According to the United States Pharmacopoeia (USP),

pharmacists can be potentially exposed to HDs while

compounding when:

• Weighing or mixing components;

• Crushing or splitting tablets or opening capsules;

• Pouring oral or topical liquids from one container

to another;

• Constituting or reconstituting powdered or

lyophilized HDs;

• Withdrawing or diluting injectable HDs from

parenteral containers;

• Expelling air or HDs from syringes;

• Contacting HD residues present on Personal Protective

Equipment (PPE) or other garments;

• Deactivating, decontaminating, cleaning, and

disinfecting areas contaminated with or suspected

to be contaminated with HDs;

• Maintenance activities for potentially

contaminated equipment and devices.

The gako PM140 decreases the risk of exposure to HDs

as it works in a closed environment provided by the PM

jars. Additionally, the PM jars can be placed in negative

pressure cabinets, which increases safety for the com-

pounding of HDs.

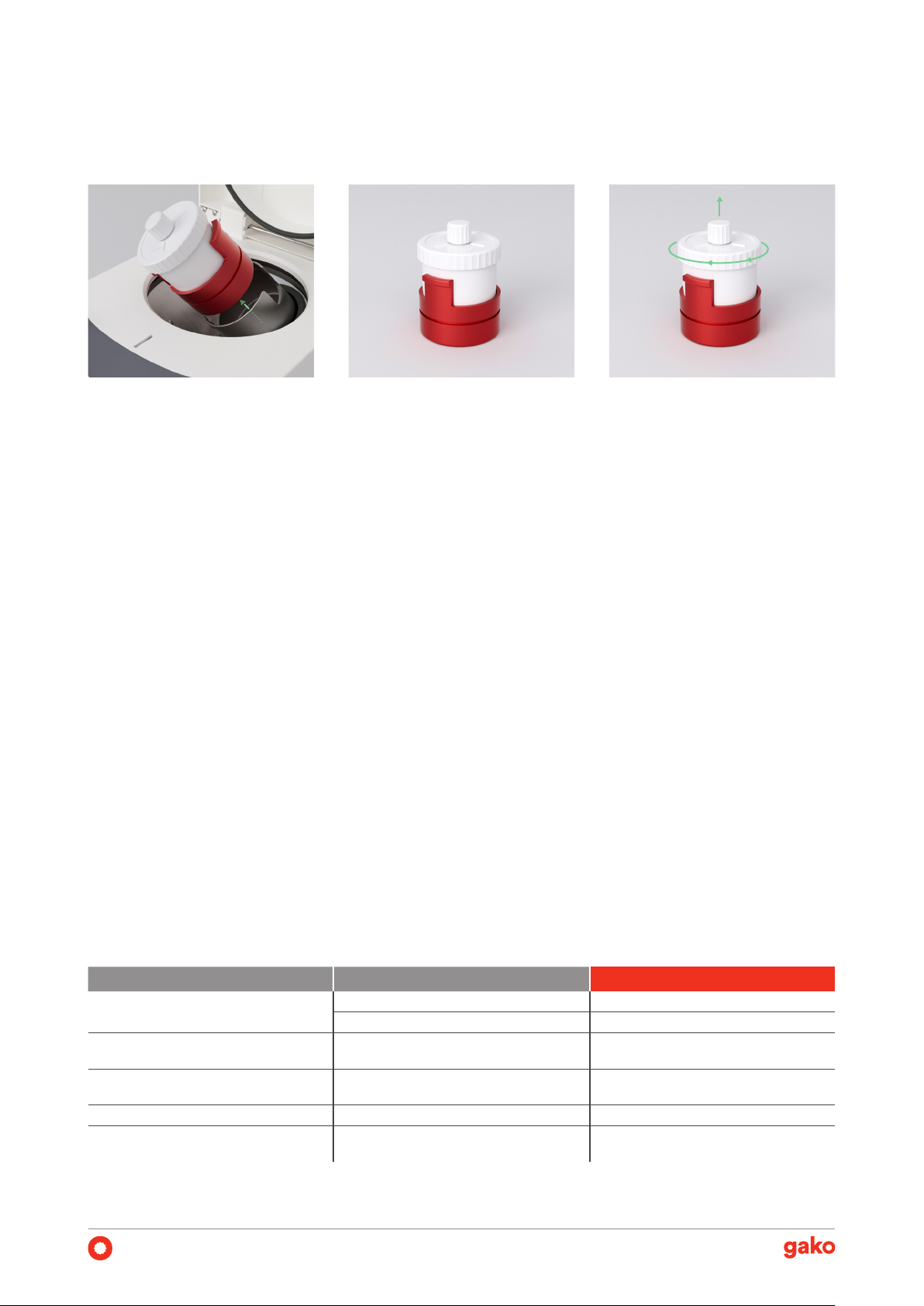

Volume-Adjustable Jar

For the preparation of smaller batches than 100 mL, the

gako PM jar 100mL HV enables the reduction of the jar

volume by pushing the bottom upwards after the op-

eration. This eliminates the requirement of acquiring

multiple jar sizes and additional jar holders/adaptors to

accommodate them with the device. Additionally, it min-

imizes air contact by removing excess space, resulting in

improved quality.