1 THE MPI DC SERIES ..........................................................................................................................................................................................5

1.1 Field of application............................................................................................................................................................................................5

1.2 Models and versions .........................................................................................................................................................................................5

1.3 Components lay-out ..........................................................................................................................................................................................6

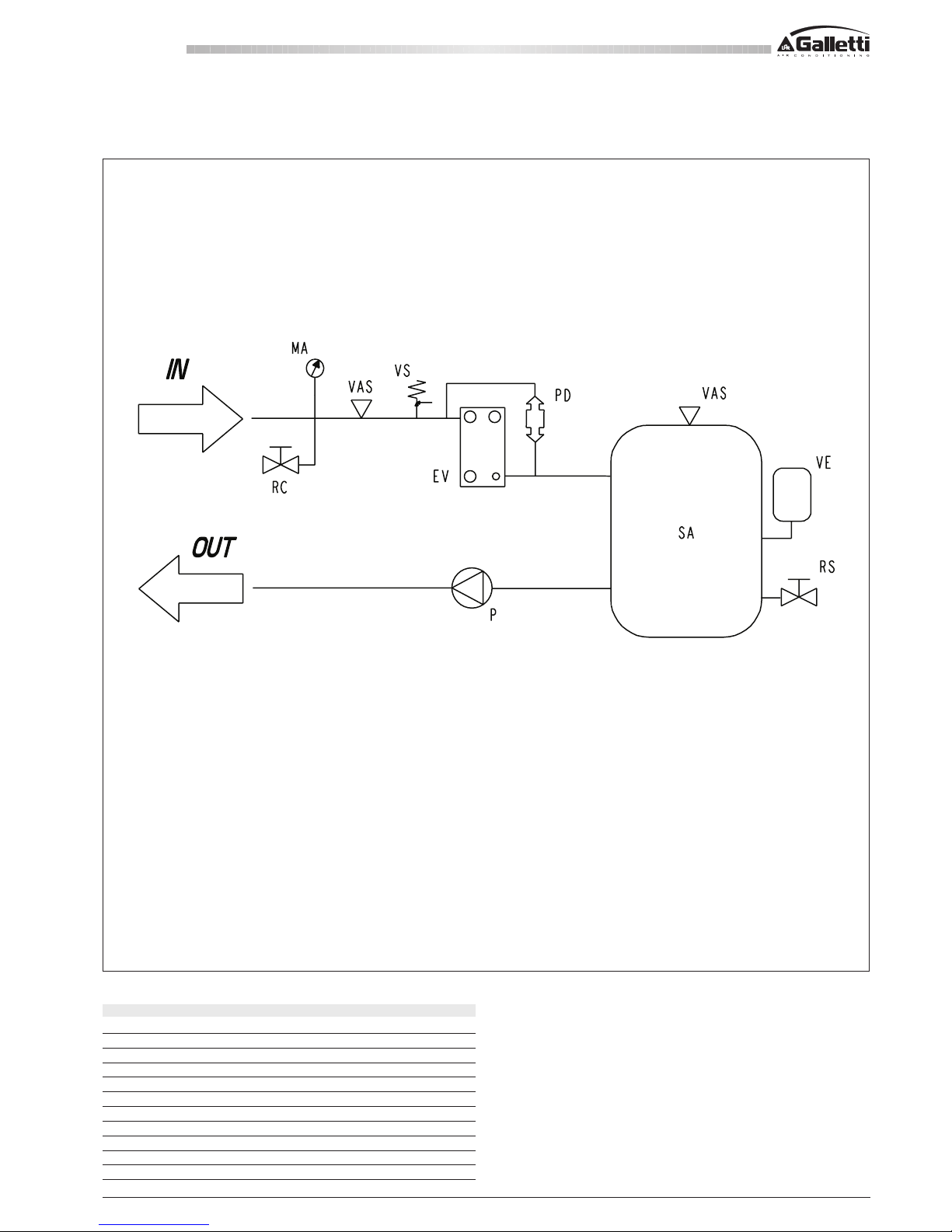

1.4 Water circuits....................................................................................................................................................................................................8

2 INSPECTION, CONVEYANCE DIMENSIONAL AND SITING.................................................................................................................................10

2.1 Inspection........................................................................................................................................................................................................10

2.2 Conveyance.....................................................................................................................................................................................................10

2.3 Dimensional ....................................................................................................................................................................................................11

2.4 Siting...............................................................................................................................................................................................................13

2.4.1 Installation clearance requirements ...................................................................................................................................................................13

2.5 Dampers siting................................................................................................................................................................................................15

3 PLUMBING AND ELECTRICAL CONNECTIONS .................................................................................................................................................16

3.1 Plumbing connection.......................................................................................................................................................................................16

3.1.1 Hydraulic connection........................................................................................................................................................................................16

3.1.2 Recommended water circuit .............................................................................................................................................................................16

3.1.3 Filling the system..............................................................................................................................................................................................17

3.2 Electrical connections .....................................................................................................................................................................................17

3.3 Electrical data .................................................................................................................................................................................................18

4 STARTING UP ..................................................................................................................................................................................................20

4.1 Preliminary checks..........................................................................................................................................................................................20

5 MICROPROCESSOR CONTROL ........................................................................................................................................................................21

6 OPERATING LIMITS .........................................................................................................................................................................................21

6.1 Operating limits in chiller mode ......................................................................................................................................................................21

6.2 Operating limits in heat pump mode ...............................................................................................................................................................21

6.3 Thermal carrying fluid.....................................................................................................................................................................................21

7 CONTROL AND SAFETY DEVICES ....................................................................................................................................................................22

7.1 Control devices................................................................................................................................................................................................22

7.1.1 Service thermostat ...........................................................................................................................................................................................22

7.1.2 Control device settings .....................................................................................................................................................................................22

7.2 Safety devices.................................................................................................................................................................................................22

7.2.1 High pressure switch........................................................................................................................................................................................22

7.2.2 Low pressure switch ........................................................................................................................................................................................22

7.2.3 Antifreeze thermostat........................................................................................................................................................................................22

7.2.4 Water differential pressure switch .....................................................................................................................................................................22

7.2.5 Water safety valve ............................................................................................................................................................................................22

7.2.6 Safety device settings.......................................................................................................................................................................................22

8 ROUTINE MAINTENANCE AND CHECKS...........................................................................................................................................................23

8.1 Checks to be performed by the user................................................................................................................................................................23

8.2 Checks and maintenance to be performed by specialised personnel..............................................................................................................23

9 RETIRING THE UNIT ........................................................................................................................................................................................24

10 TECHNICAL FEATURES....................................................................................................................................................................................24

10.1 Water chillers rated technical data .................................................................................................................................................................24

10.2 Heat pumps rated technical data.....................................................................................................................................................................25

11 COOLING CIRCUITS.........................................................................................................................................................................................27

12 TROUBLESHOOTING........................................................................................................................................................................................28

INDEX

The technical and dimensional data reported in this manual may be modified in view

of any product improvement.

TRANSLATION OF ORIGINAL INSTRUCTIONS

WATER CHILLERS AND HEAT PUMPS ARE IN ACORDARCE WITH THE

LAW 97/23/CE (PED) FILLING IN D1 FORM, APPROVED BY THE THIRD

NOTIFIED BODY ICIM N°0425.