IMPORTANT:

- INSTALLATION COMPLIANCE: Galvin Specialised products must be installed in accordance with these

installation instructions and in accordance with AS/NZS 3500, the PCA and your local regulatory requirements.

Water and/or electrical supply conditions must also comply to the applicable national and/or state standards.

Failing to comply with these provisions shall void the product warranty and may affect the performance of the

product (Refer to installation compliance sheet supplied with the product).

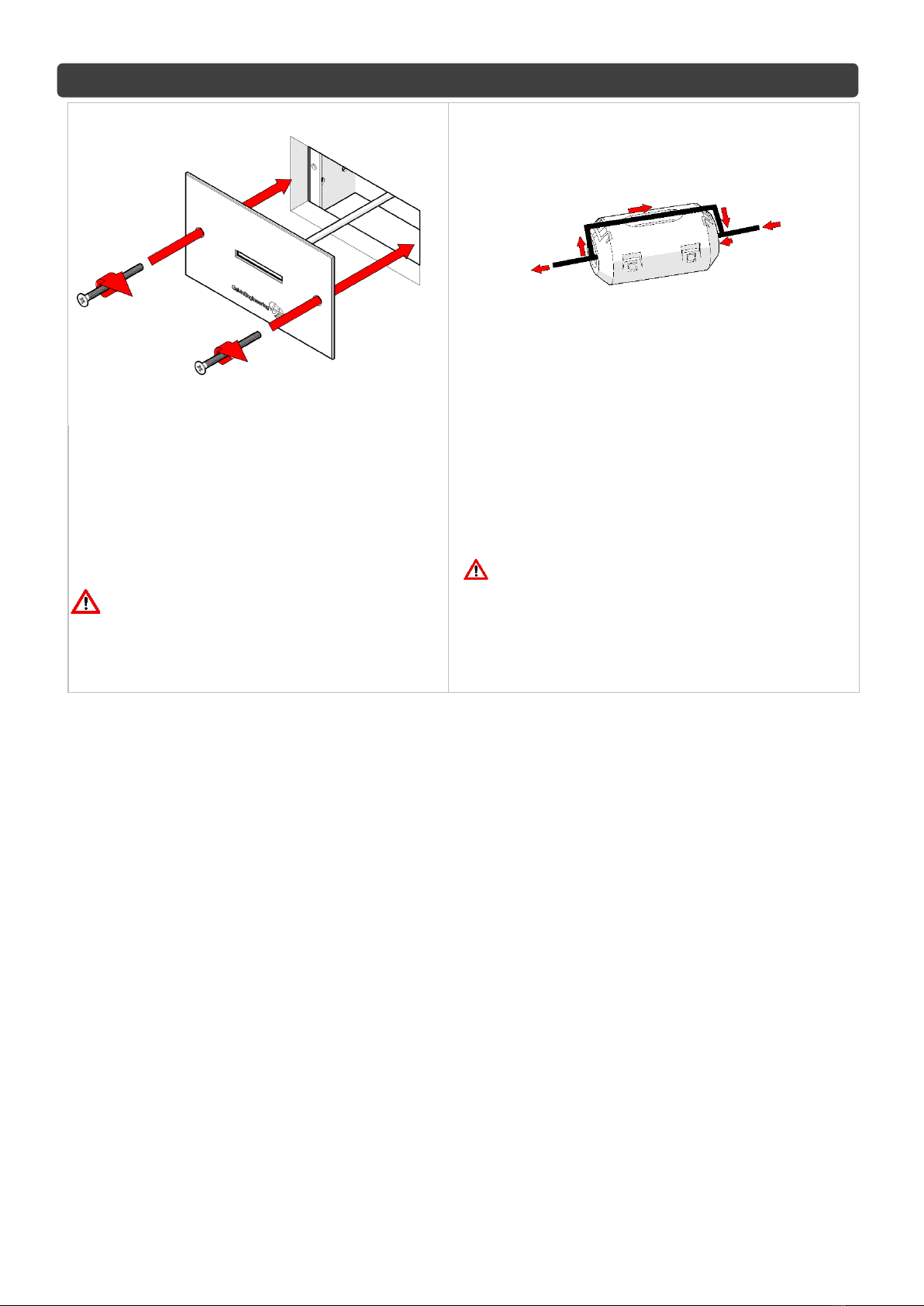

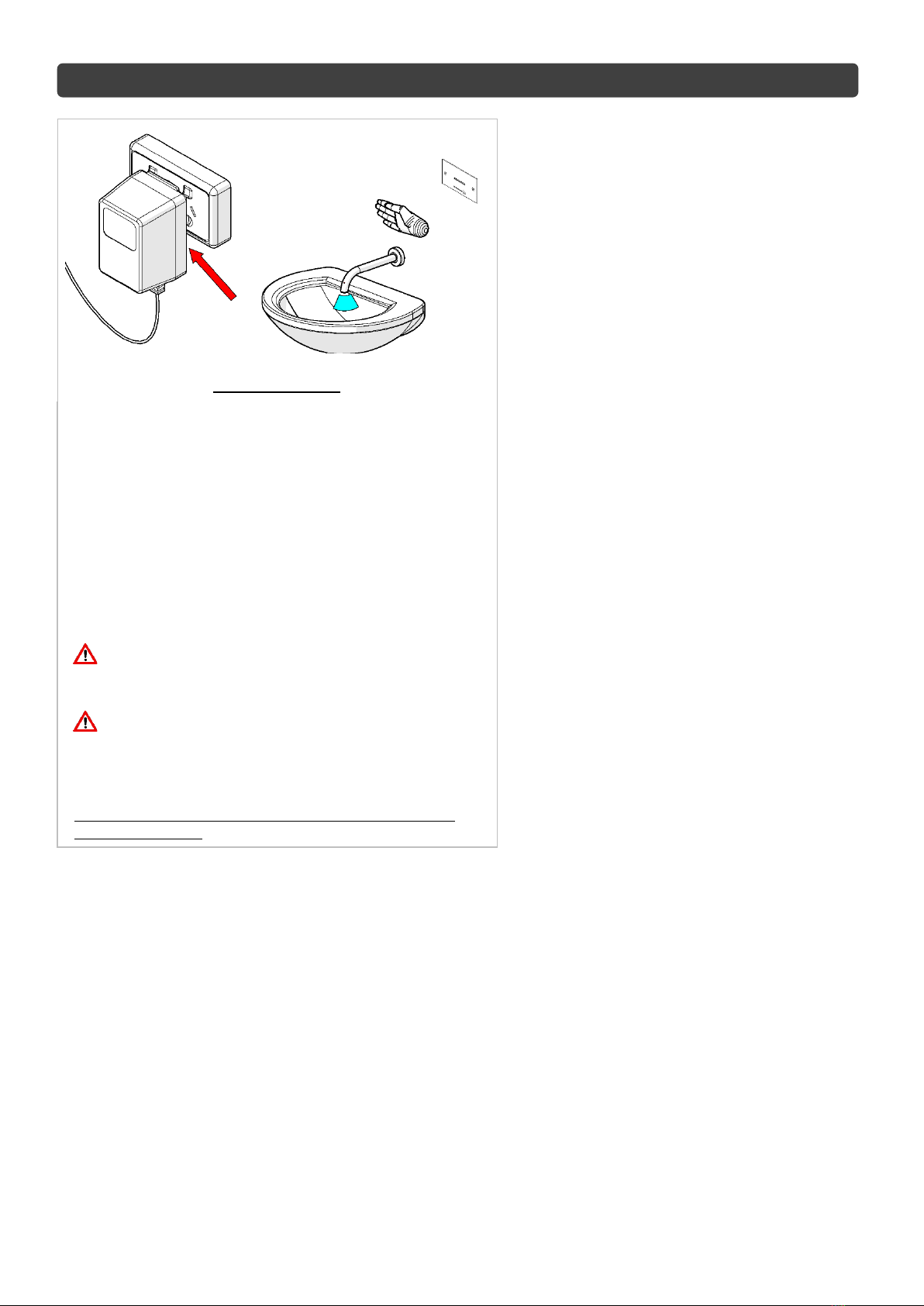

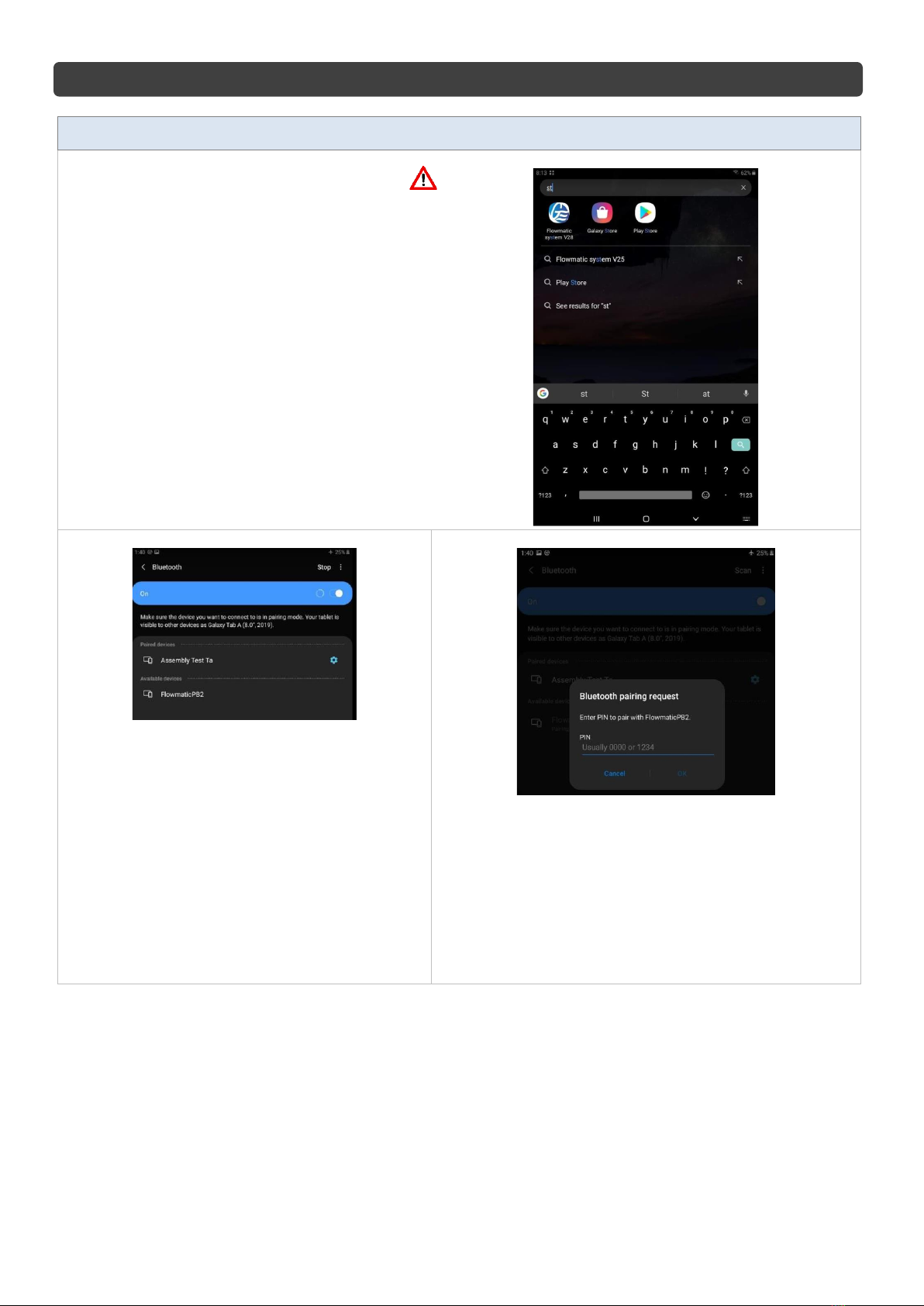

- Ensure that access to the sensor, solenoid valve and transformer/GPO is available for future maintenance when

installing the components. It is recommended that isolating valves be installed upstream to the solenoid valve to

allow for servicing. All wiring must be able to be removed when installed into cavities or walls, therefore, it is

recommended that a minimum of 25mm conduit be used to house the leads. The unit is supplied with 3 meters of

lead on the transformer and a 5 meters lead from the solenoid. Additional lead lengths may be accommodated up

to a length of 5m but must be ordered separately.

- Whilst our product designs take into account a broad range of installation types and surfaces, it is important that

surfaces which fixtures are mounted to are flat and free from defect. Additionally, ensure any protruding

connecting thread is square to the wall so that the outlet sits flat against the wall when installed. This is especially

important when installing product ranges that have been designed for correctional and health facilities, where

special attention is required to minimise ligature points and areas for concealment of contraband. In addition to

ensuring the products are fitted securely and in accordance with the following instructions, consideration shall be

given to the use of non-pick mastics such as BASF Sonolastic “Ultra” to ensure a high quality and safe

installation.

- Most installation problems are due to damage to the unit during installation or the selection of an inappropriate

installation location. Select the location carefully and take care with the installation, consider ease of operation for

the end user.

- It is advised that the sensor should not be positioned directly in front of reflecting surfaces, such as ceramic tiles,

stainless steel basins or mirrors. Any bright lighting reflecting off a highly reflective surface such as a stainless

steel basin, or a high visibility reflective vest, may interfere with correct sensor operation (Refer sensor settings

for operation and adjustment)

- Do not cut or extend the existing leads without using a correct lead extension from Galvin Specialised, as

this will void warranty.

- Suitable access to the service of all components must be provided.

- Do not apply heat near this product when connecting water lines. Heat generated by soldering could

damage plastic or electrical parts and seals, and will void the warranty.

- For personal installation assistance and spare parts, please call our head office on 1300 514 074 and

speak to our customer service staff.