CHECK CONTENTS

- Separate all parts from the packaging and check each part with the pack contents section.

- Make sure all parts are present before discarding any packaging material. If any parts are missing, do not

attempt to install your electronic faucet. Contact Galvin Specialised.

WARNINGS

- Do not install the system facing a mirror or any other electronic system operated by an infra-red sensor.

- To prevent reflection problems, it is recommended to keep a minimum distance of 300 mm between the soap

dispenser and any other objects.

IMPORTANT:

- Keep in mind that when using the faucet installed next to the soap dispenser, the user hands should not

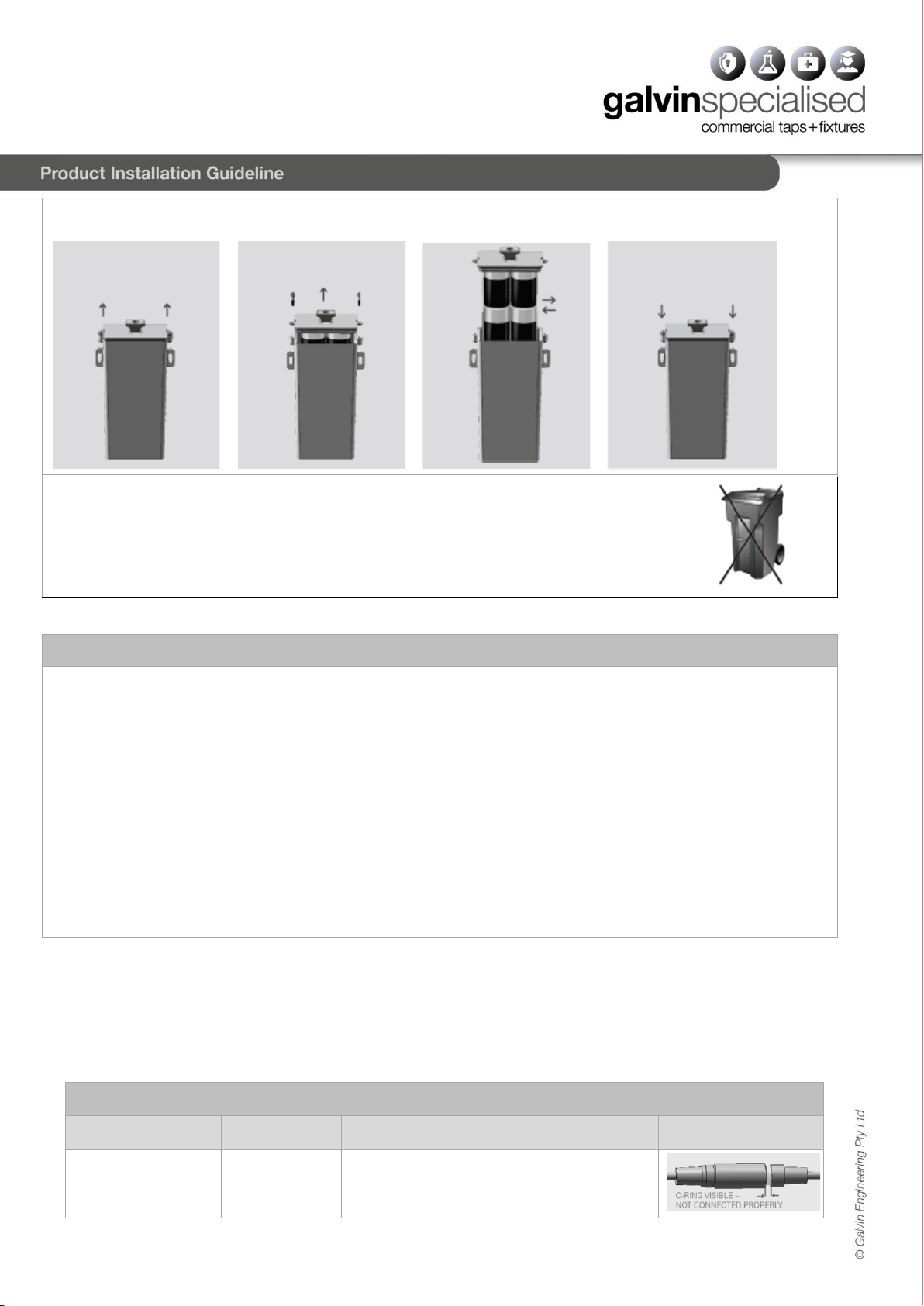

interfere with the soap dispenser sensor detection area. Liquid soap dispensers, with proper care, will provide

long term trouble free service. Quality liquid soap of recommended viscosity and pH levels are the main factors

for smooth operation of your dispenser. If needed, use a viscometer to verify the viscosity of your soap to

ensure maximum benefit. The recommended range for liquid soap viscosity is 100-3800 cPs. Thicker liquid

soap flows slower and inhibits the pump valve, causing strain and damage.

- Liquid soap dispensers are suitable for use with any generic liquid soap of the correct viscosity and pH. The

pH level of all soap used in our liquid soap dispensers should be between 6.5 to 8.5. Lower levels will cause

corrosion to the metal dispenser and even the rubber and plastic components. Higher pH levels will cause

swelling to rubber parts and degradation of plastic components over time.

IMPORTANT: Galvin Specialised products must be installed in accordance with these installation instructions

and in accordance with your local regulatory requirements. Electrical supply conditions must also comply to

the applicable national and/or state standards. Failing to comply with these provisions shall void the product

warranty and may affect the performance of the product.

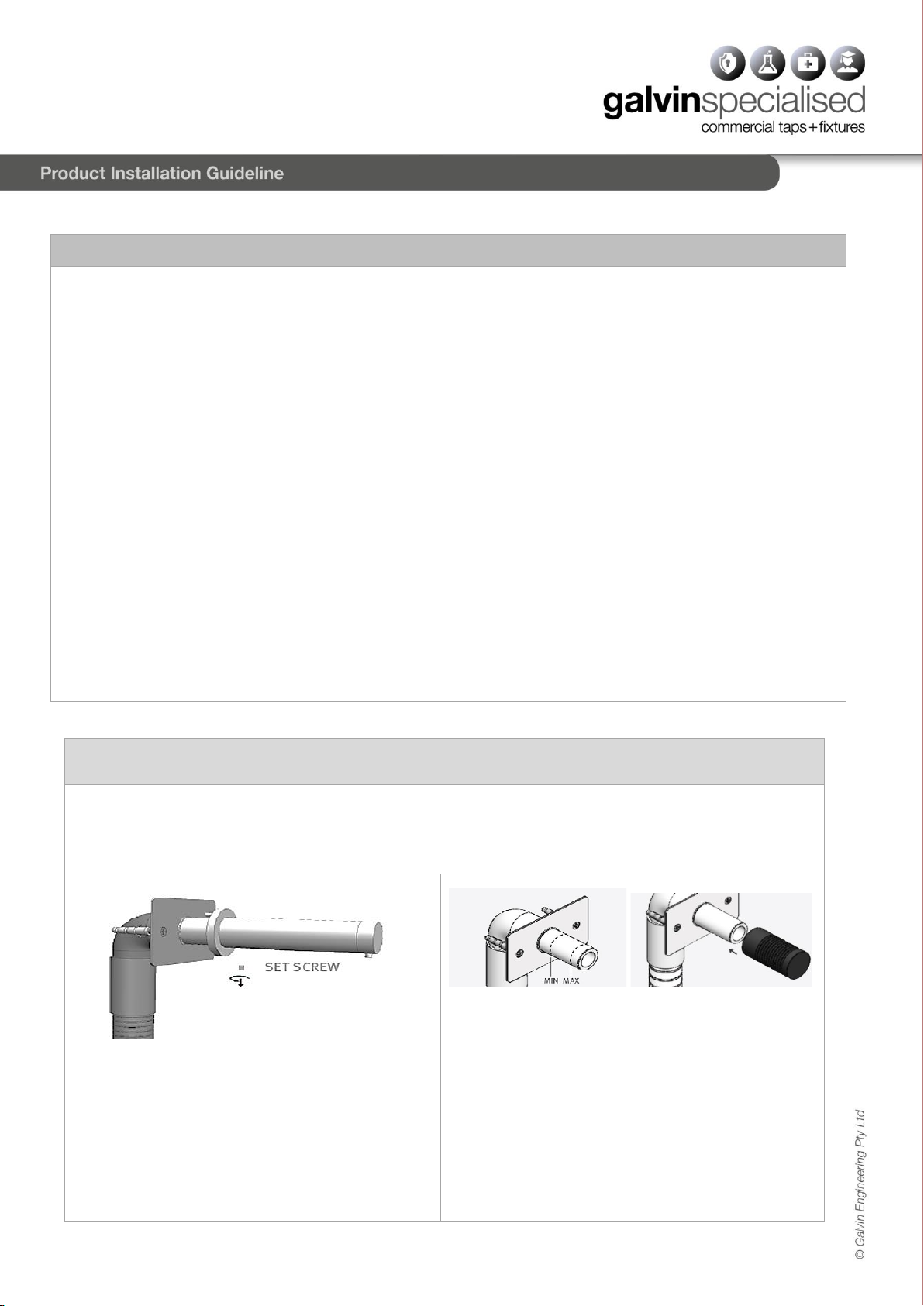

1. Drill hole & Disassemble body

- Drill a hole (23 to 24 mm) at the desired location

for the soap dispenser spout installation.

- Remove the hexagonal nut and the disk from the

base of the soap dispenser spout.

- Disconnect the soap dispenser body with the

rosette from the base by unscrewing the grub

screw.

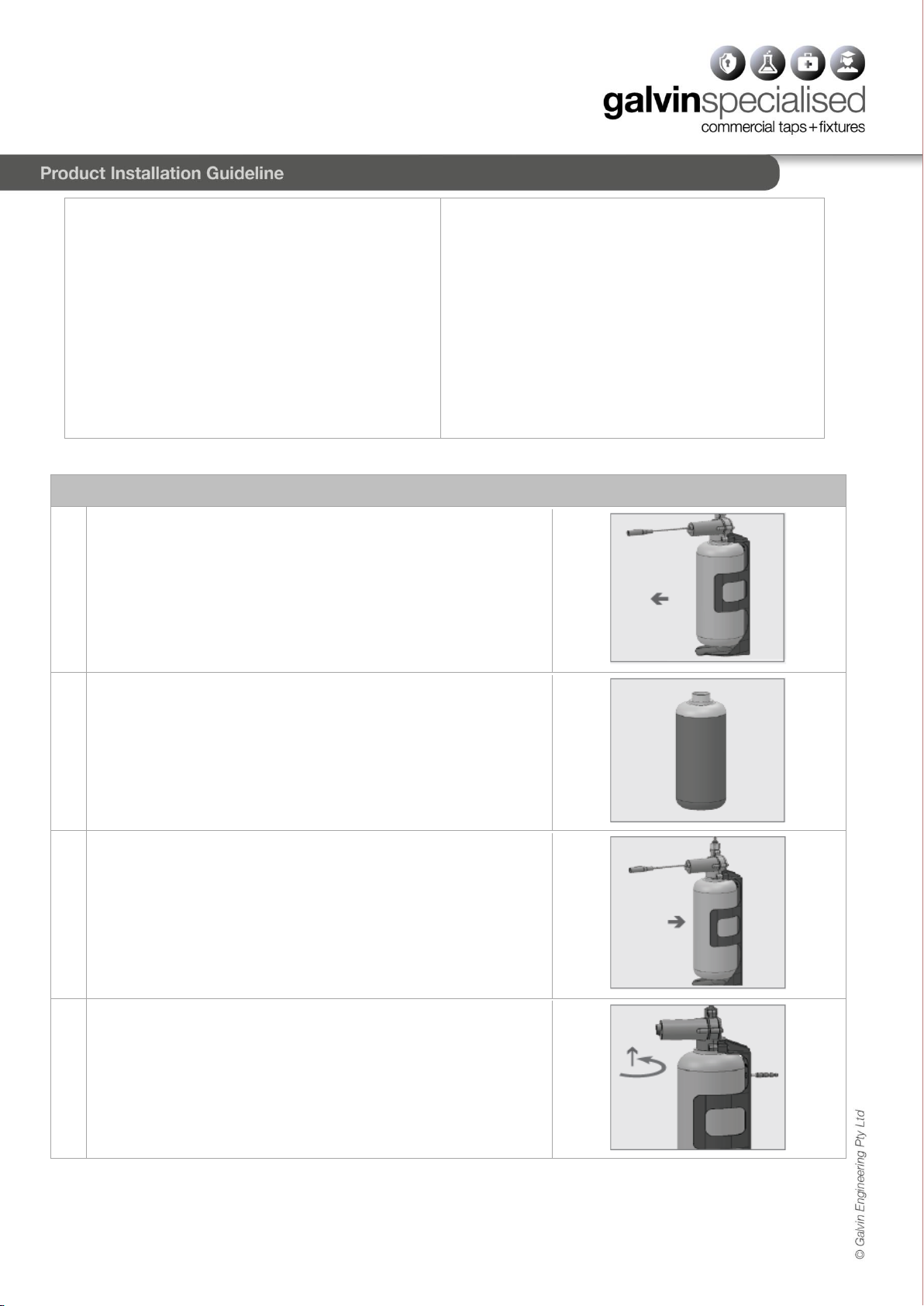

2. Mount Soap Dispenser

- Mount the soap dispenser base into the opening

in the wall and secure it using the anchors

provided in the package.

- IMPORTANT: The soap dispenser base should

be installed so that the outside surface of the

finished wall falls between the minimum and

maximum lines marked at the base.

- Assemble the temporary protective soap

dispenser base cover.